-

Posts

155 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Tommie Hockett

-

i have one exactly like the top one I was told it had something to do woth horseshoeing/farrier work but that could be very wrong so dont take my word for it.

-

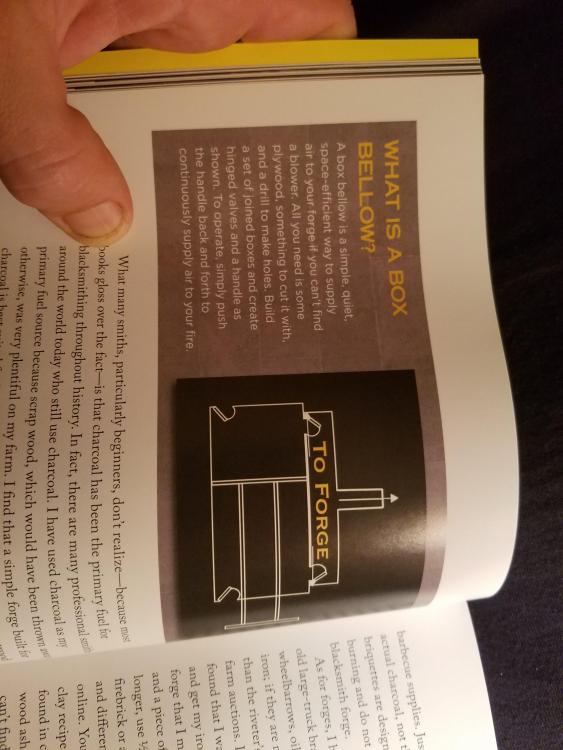

allrighty then sorry I havent been on much yall they had me busy on my off week. gotta live the oilfield... I need a raise haha. Anyway I did find time to get most of my honey do list done and got the forge built. I didnt cut holes in both sides I figure if I need to I can always do that later. Im back out in West Texas for a week but when I get back the homemade refractory cement should be cured. I used clay, sand, wood ash and perlite. I also embedded some volcanic rock in the sides to help reflect the heat. I dont know how well it will work but it sounded like a good idea haha. anyway you cant see the holes in tuyere but i promise they are there about every half inch give or take. Im gonna try and rig up a homemade blower from the diagram that i posted. I will have to do some tweaking to get it to work with mine but I think it can be done. Anyway let me know what yall think!!!!

-

Haha I would have but I didnt realize until I was through it that it was where you lived. But who knows with the way my work is going I may be in Oklahoma off and on for awhile

-

Also that is a dang good lookin forge thats hot

-

thanks guys Thomas you are absolutly correct I overthink alot of things haha, my bad. I will be home early in the morning so after I finish my regular chores I will start on building the forge and let yall know. thanks for having patience with a newbie. As a side note to Charles I just drove through your town

-

well I saw one made using the shell of a bbq grill. So that got me to thinking I have a very old homemade gas grill that is made from 1/4 inch plate steel. we havent used it in years and I dont trust the homemade gas ports, but what I was thinking is making my own refractory cement with clay wood ash and sand. anway making a trench forge out of it amd using the existing gas pipe for the tuyere just drilling put the ports a little wider for better airflow. I would have to cut out the side to get the stock into it. should I cut out both sides of it like tim lively's forges. I have decided to use charcoal because of the advice yall have given me on trench forges and the availability. also what I have read is that bottom blast is good for forging but not great for forge welding. So what I was thinking is maybe putting a pipe in from the back and just alternating the airflow depending on what Im doing. I need some advice on that please. Also please excuse any typos I try to go back and proof read but I have big thumbs and a small phone haha.

-

thats awesome you only live about 4 hous south of me.

-

holy crap so I have been looking at tim lively's stuff this entire time. and I ran across several different variations and some information on how to properly use a rail road rail as an anvil... I have alot of things to think about but I already have a plan in my mind and I will share it with yall on the morrow. goodnight yall

-

Thomas sir so far you are a scholar and a gentleman I appreciate you sharing your knowledge with me.I am going to look up the tim lively forges right now. Thanks again.

-

Haha thats awesome guys thanks for the offers I may just have to take yall up on at least the visiting part of it. where abouts are you from little blacksmith?

-

Right in Thomas thanks for the advice.... I almost hate to ask but do you have anything for me on the dimensions on the fire pot? Also glad yoj said that about the cement I wasnt going to use actual cement but that was my train of thought about the lime haha. So I will definetly leave that out

-

wow you live around where I work sometimes. done alot of work around El Paso our man camp is about 2 hours north east of that in Pecos Texas

-

no I've never heard of Dalhart before the nearest big city would be Ft Worth and it is just a little over an hour South of me.

-

Thanks for the info Charles. Thomas its my bad I need to be more specific... I reckon since its been done by alot of people for decades then it would be a good idea. my actual questions are should I make it side blast or bottom blast? which one would be best? And I was wondering if there is a magical measurement that everyone uses for their firepots. i.e. length depth and width. Also thanks for the tip on the neo tribal smithing I will have to look it up tonight, headed back to the hotel now. I have one more qyestion rattling around in my head.... So in some modern adobe buildings they use lime to help stabalize the structures. I am also fairly sure that lime is costic in powder form. if I added it to the clay and sand mixture would it help prevent heat checking and if so would it put off toxic fumes when heated?

-

as far as coal being better I meant to say that I have read that coal is better... I have no proof of good or bad quality of either one. I am solely going on what I have read on the internet and a few grit magazine articles. Awesome news on the rig cable!!. I have had my eye on the foxfire series for awhile I just havent bitten the bullet and boight them yet. I think they would be very interesting and handy, there is alot of nearly forgotten knowledge in there.

-

Good to hear from yall guys. Thanks for the warm welcome. Fristy as far as tge firge I am going to start on it on my off week. which was supposed to start minday morning but we have a big job about to pop off so its looking like I wont be home until tuesday night. I am thinking avout building a jabod forge out of a #2 washtub that I have I posted a thread asking advice avout that i. the solid fuel forge catagory. I am hoping to use coal.... Ive read that it is better than charcoal or wood and I dont have the expertise or money to build a propane forge. As far as what I want to make..... of course I want to learn hiw to make a knife or three.... (who doesn't haha) but i also want to learn to make hinges because whenever I am building something I never seem to have the right size or only one of a particular size and I would also like to learn to make nails. I think that it would be very gratifying to build aomething drom lumber that I have milled my self with nails that i forged and maybe uaing a hammer that I forged haha. My anvil until I find a proper one is a very long piece of railroad iron that I acquired a few years back. Thomas thank you for the book referencea, I will have to check them out. The work I do in the oilfields is reatraing ground iron for frac sites and cement pipes when they set in the casing. also we lay out containments to catch any spilled chemicals and make epa happy haha... so no scrap for me. :(. However I do have around 300 ft of 3inch drill cable that i thought would make an awesome pattern if it is hardenable...??? my dad bought aome land here while back and it was an oil field graveyard so there is alot of stuff there. Also thanks for the refernce to the school Texarkana is only 3 hours away from me I live in the texoma area about 10 miles from the river. I wil see if I can edit my original post to include that in my header. Thanks again for the warm welcome and if yall have time check out my post in the solid fuel forge section.

-

Howdy yall. So as promised in my intro here is my first question. I am just getting started and I plan to build a coal forge. I have an old number 2 wash tub and I was curious on what yall thought about maybe putting a pipe in the middle of it and sculpting a fire pot into it with clay. also I have seen forges with and without hoods do I need one and does a hood help with heat retention. my forge will be basically outside I have a back patii with 3 foot pony walls and a tin roof over it. thays where my forge will be.

-

howdy yall! my name is Tommie... obviously haha. I am just a beginner and I reckon I will make a lot of mistakes in my quest to become a blacksmith. But I will do my best to learn from them and to listen to the experienced hands here so that I do not make quite as many. My wife Chellie will also be joining me on this journey, however she probably wont make a login... other than to read the news and do research she does not play on the internet very much because we have very bad signal at the house and we live so far out the only thing available is dial up or satellite (expensive).. Anyway I work in the oil field so I travel alot and have down time to just be on my phone sitting in the truck so yall will probably hear alot from me. My job has a lot of hurry up and wait going on. Anyway I jave a lot of hobbies I am an accomplished wood worker and I build my own rifles and reload my own ammunition and cast my own projectiles. my ultimate goal in life is to own my own land and be a homesteader. Recently My wife and I have became very interested in blacksmithing and I have alot of questions but I will post them in the appropriate categories. Anyway now yall know about all there is to know about me and I hope to hear from all if yall soon. yall have a blessed evening!