-

Posts

167 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Stitch

-

-

-

Perhaps a local CNC wire cutting service?

-

Beautiful, beautiful work 58er!!

-

Very nice stake Das!! By the way, I have a spot picked out for you to park your trailer on my property......

Permanently! Ha!

-

Nice repair Hans!! saved some $$$ too...

-

That is really cool Das! I will make one for dedicated radius bends for sure!

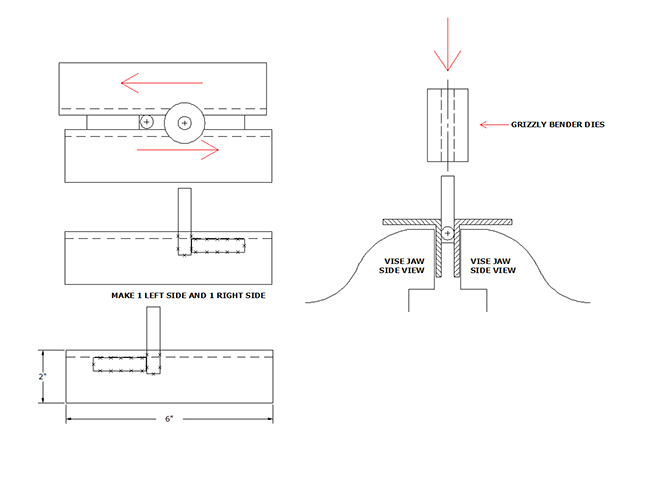

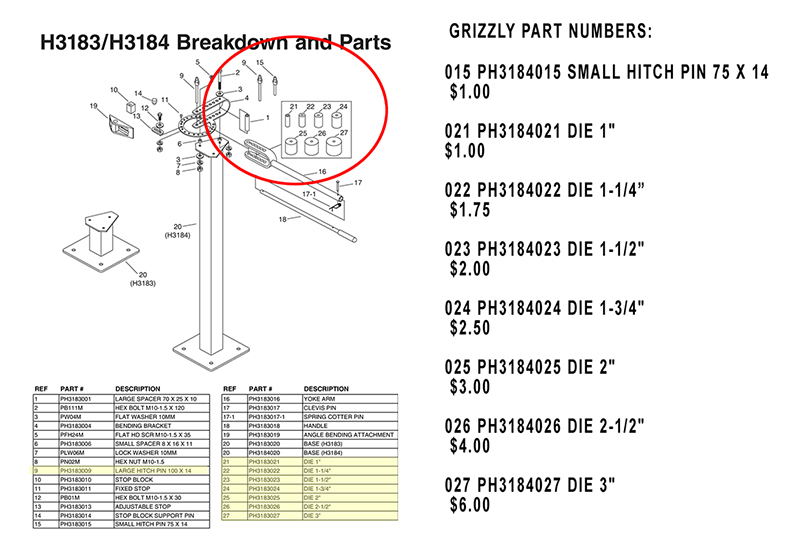

I made the sliding angle iron style one for bending various thickness of steel a couple years ago using

bender dies from a Grizzly Bender. Works great! I bought the roll dies cheaper than my brother could have bought the stock and machined them for me!

I didn't have a picture handy of the set up but here is a sketch and part numbers and prices:

-

Very, very nice!!

-

Das, John,

I am truly inspired I now have a great use for that Jackhammer bit John gave me!

-

I just love your Mantis's or Manti' Aus! I better not show the wife or I'll be trying to make one!

1 hour ago, jlpservicesinc said:Not sure how anybody else feels about it, but I have seen fires in a tight area from forging/forge welding..

I have contemplated the solar and battery storage in the trailer but decided against it because of having the batteries inside the trailer and the hydrogen vapors as well as a rogue hot ember/metal getting away without noticing..

I suppose if I wanted to buy a couple of those dry matt batteries which are vent less and can be turned any direction is wouldn't be much of a problem hydrogen vapor problem..

We used a boat battery box mounted to the trailer tongue. No problems that way!

-

Hey Das,

Put a H.F. 100 watt solar panel set up on the top of the trailer. My son did that to his and kept a deep cycle

battery charged up to run a bunch of LED lights, a 12v tire air compressor, cell phone chargers and some 12v doo-dads in his trailer.

It worked fantastic in his cross country move. Just suggesting......

-

Thanks Das! I like the Rasptlesnake idea. Hammer Monkey, That is a superb rasp tomahawk. Nice job!

-

58er' That is some cool artistry! You've got some patience buddy!

Well the wife wanted me to continue on the garden Snake theme..... So I decided to up the game and try a rasp Snake. Good use for a worn Farrier's rasp. The darn thing wanted to twist constantly while hammering it in the swage block.

Turned out OK for the first try though.

I have a real cool idea for my next Snake project. Starting tomorrow.....

-

Hey! All great ideas guys!

-

I can laser cut a custom gasket or washers for you John....

-

-

6 hours ago, Charles R. Stevens said:

When you are as hair brained as I am, bellows and crank blowers are a god send. I have found I like chain saw bar oil the best for the hand cranked blowers.

Thanks for that tip Charles! My brother just happens to have a 55 gallon barrel of it!

Looks like I'm going on a raid!

-

Really works great Das, Come over and try it!

-

First test of the new forge and Wow!! I can't believe how great it draws... I set some lump charcoal in it with a small wad of paper and it took off

like a F-111 in full after burner. And that was without using the blower! My buddy and I forged for 4 hours Sunday and I've never had a better

fire to work with. We hardly had to use the blower, only when we needed the extra heat. hat 36" tapered cone and 16" diameter stack must work like a super vortex.

Very happy with this project. Now on to the surface grinder/belt grinder project...

-

On 3/17/2018 at 1:02 PM, JHCC said:

On the way back from picking up my daughter for her spring break, I stopped at the Amish blacksmith supply and got a farrier’s rasp off the Sale table and a sack of blacksmithing coal. I haven’t forged with bituminous in years, so we’ll see how this goes.

(Also stopped at TSC for a couple of sacks of rice coal, just to be on the safe side.)

Once you go bituminous , you never go back! LoL!

-

Hey,

Thanks guys!

-

I scored another load of new hammer bits. Stopped in at my local industrial surplus place and found these babies.

48" long, 3/4" shafts new old stock. I got them pretty cheap. My spring time stock of new chisels and punches!

Probably summer, fall and winter for the next two years...... Stop in and get some JHCC!

-

I hear that! Going the this morning.. Got a great deal on a small blower.. $5.00 Picking up a welding table too..

-

Hey Das,

It's a big boy for sure! I have a pass through planned. I have to draw up the cut template..

-

Hi John,

Please tell me you made two sets and have an extra set up just laying there waiting for some needy local smith. Ha!

It followed me home

in Blacksmithing, General Discussion

Posted

I'D be interested in some of that 4140! LoL!