Rsparozi

Members-

Posts

14 -

Joined

-

Last visited

-

Tempering 1095 blades to blue

Rsparozi replied to Rsparozi's topic in Heat Treating Knives, Blades etc

I’ve got some spare 1095 from the original blank, I think I’m going to chop it up and try different methods for treatment. I’ll give the soak a try Steve, thanks for your suggestions. For the sake of science I went thru every knife I’ve ever made since I started a few years ago, turns out heat treating mystery steel yields highly inconsistent results, even if they were all made from files. I got hardness ranges from above the 65 file down to between the 40 and 45 files. No more mystery steel for me. -

Tempering 1095 blades to blue

Rsparozi replied to Rsparozi's topic in Heat Treating Knives, Blades etc

Good Evening, I hope I’m not dragging this thread along, but I thought it would be a good update. I purchased the hardness testing files from flexbar and tested the knives from the original post, the ones that tempered to blue. Looks like they tempered somewhere between the 50 and 55 files. Great recommendation to go for the hardness testers, will help me to refine my heat treating process. -

Tempering 1095 blades to blue

Rsparozi replied to Rsparozi's topic in Heat Treating Knives, Blades etc

Good evening everyone, hope you had a productive weekend. Just following up, I tempered another stock removal blade from 1095 this evening. As was recommended a few weeks ago, I purchased an oven thermometer to confirm what temperature range my oven would cover over the course of the 2 hour temper. I set the oven to 400F, brought it up to temp, put the blade and the probe in. The results were nothing short of shocking. Over the two hour time frame, the oven ranged from 387F up to 458F. I can’t imagine those fluctuations are anywhere near acceptable. Needless to say, from here on out I will do what Buzzkill recommended and fill a pan full of sand to add thermal mass to help stabilize the temperature fluctuations. Thanks for everyone’s input, great advice all around. -

Tempering 1095 blades to blue

Rsparozi replied to Rsparozi's topic in Heat Treating Knives, Blades etc

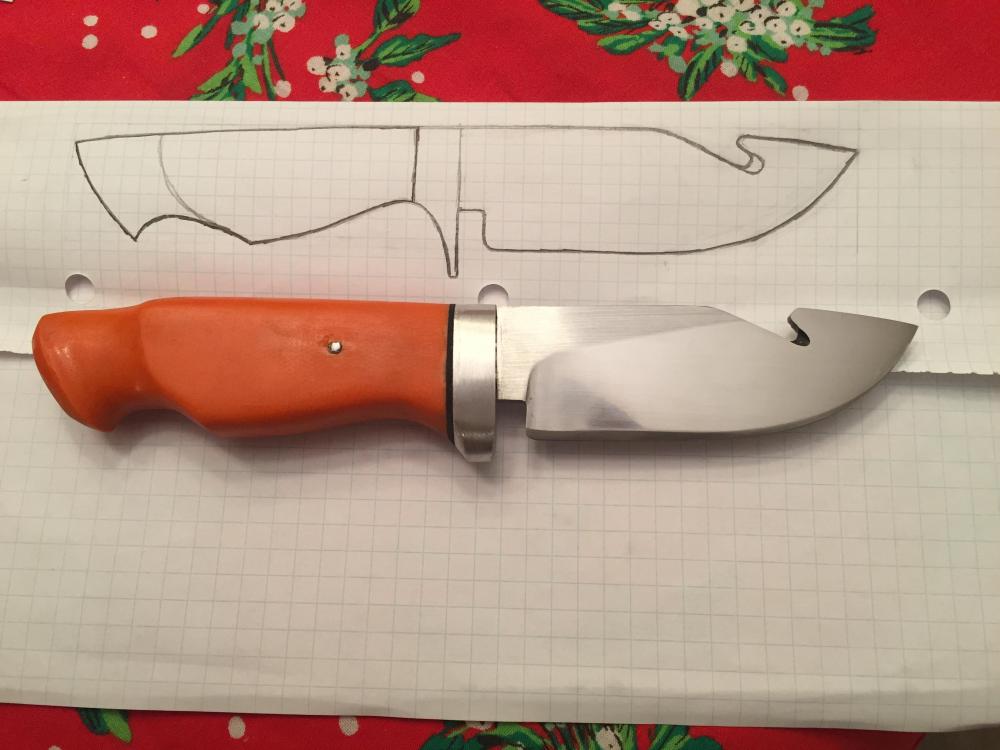

Good Morning All, I thought it would be nice to post a pic of one of the finished knives in question from my original post. For me personally in my novice state, its not a bad knife, it’s probably my most technically complex to date with the gut hook, differential heat treat, and pinned hidden tang with the contoured G10 handle, and for that I’m very proud to create something that was better than my last blade. I had to add the black spacer which was unplanned due to some wobble, but I like it as an accent piece. It is far from perfect, but Rome wasn’t built in a day, and neither will my skills as a knife maker come to full maturity over the course of making a single knife. I can’t crush myself for not producing a flawless knife when I’m just still very much a noob. I’ve acquired a lot of new skills I plan carrying forward, and intend to improve on each of them on the next knife. Thank you to all the took the time to comment and offer up advice, it’s really appreciated, and has not fallen on deaf ears. Happy Holidays! -

Tempering 1095 blades to blue

Rsparozi replied to Rsparozi's topic in Heat Treating Knives, Blades etc

-

Tempering 1095 blades to blue

Rsparozi replied to Rsparozi's topic in Heat Treating Knives, Blades etc

Yes I’ve heard about those as well as the knife hardness files. Seems as though they are a worthwhile investment, especially if the intent is to one day sell knives as a source of income. If anyone knows of a good product from a reputable source for either I’d be interested to hear, otherwise it’s USA knife Maker or Knifekits.com! -

Tempering 1095 blades to blue

Rsparozi replied to Rsparozi's topic in Heat Treating Knives, Blades etc

Great advice guys, thanks. I checked them with a file, skated right over. Went back to the annealed piece of 1095 for a reference feel and can easily feel the difference. Not worried about these being hard anymore, so I’m gonna finish them. I bought a cheap oven thermometer at WalMart today that goes up to 500F, from here on I’ll be double checking my oven temps like you recommended. Really appreciate everyone’s input, thanks again. -

Tempering 1095 blades to blue

Rsparozi replied to Rsparozi's topic in Heat Treating Knives, Blades etc

Thanks for the reply Sly, for clarification I didn’t quench the normalizing heats or the temper. The normalizing heats I allowed the blade to go to black heat, and on the temper - I only did one so far - I pulled the blade from the oven and let it cool wrapped in a blanket down to room temp. I also find it interesting how there’s such a distinguishable color line at where the clay covered the blade. The dark straw at the spine would have been my preferred color, but it seems the color is independent of blade thickness and more related to the steel type. While all this leaves me scratching my head a bit, I have to admit it only pulls my fascination with blades and metallurgy a lot deeper. Looks like I’ve got some reading to do. -

Good Evening all and Happy Holidays... I have a concern regarding two 1095 blades I recently heat treated. I’ll give a little background on the process I performed so you get a more complete picture. Both blades are stock removal from 0.156” 1095. I attempted creating hamons on each blade using high temp furnace cement. After grinding the blades to shape, I normalized four cycles from non magnetic working the temps down to a very dull red almost black heat. Once cool to the touch, I applied the high temp furnace cement and let sit for nearly two days. For the quench, I used warmed canola, took the blade up to non-magnetic, let it sit for another ten seconds, and quenched. Files skated, blades hardened to my level of satisfaction. Here’s where I’m concerned that I screwed up. Preferring a more durable knife and willing to give up some hardness, I set the tempering oven to 475F, and left the blades for an hour and a half. The photo below shows my colors after the hour and a half. My concern is, I’ve never taken a tempering cycle to blue, I usually prefer dark straw at the edge. Did I over-temper these? I was looking for a hardness around 59-60 RC. Any advice or experience would be greatly appreciated. Best, Rick

-

soldering guards on a knife how do you do it?

Rsparozi replied to RLKC001's topic in Finish and Polish for Knives

This is a great topic. I was searching the web to see if anyone has experience with welding a guard onto a full tang knife prior to heat treatment, but this seems to be the preferred method. I would think welding a steel guard on, grinding down excess, and then heat treating would work as well, as long as your welds do not cause any warpage in the blade. I'll have to test this method first before I roll out my welder. Thanks for the great thread, you can learn so much if you just take some time to read. -

Frosty that's great advice...Thus far I've only used fast setting epoxy -gorilla glue fast setting - which advertises a 30min setting time in which the blade is not to be handled, with full weight bearing capabilities in 24 hours. After an hour or so I will begin to do the sanding on the handle. I'll poke around on here and see where I can pick up the longer curing and will use that on the blade I'm currently working on. Thanks. Mr. Powers, that is a fair point, thank you for the correction. I've made it a point that knives I give away are only to be crafted from aged Nicholson files, feeling somewhat naively confident I guess that what I was using was quality steel. I'm sure there are many threads on here that speak to this topic, so it appears I have reading material for the rest of the evening! Once again, I thank you for the correction.

-

This was my first attempt at what I would refer to as a tanto. 1095, as are most of my blades since I come across files quite often due to my wife's business. I etched my friend's initials at the base of the blade, and completed the handle with zebra wood scales and steel pins. He's very pleased with the blade, but I perceive that it likely never gets used. As you can see the base of the blade right above the handle is a bit rough, and scales are uneven. Comes from a mix of impatience and excitement to complete it, something I need to work on. Biggest struggle I continue to have is fit and finish around the base of the blade. The grinder can take the smallest amount of epoxy and wipe it entirely across the face of the knife. My own fault for not taking the time to sit with a piece of fine grit sand paper. Still quite happy with it. Feel free to comment and critique; any helpful advice is always greatly appreciated. Best Regards, Rick

-

Thanks gents, appreciate the kind words. I purchased it online off Bell Forest Products. The wood was a beautiful piece with a lot of character, and sanded nicely to a polished finish. This photo was taken after I hit it with some mineral oil so that's what gave it the great shine.

-

Good Evening IFI community, I've been a member for about a month now, quietly reading the massive wealth of information available on the forum, and I wanted to take the opportunity to introduce myself finally, and thank everyone for sharing their experiences and knowledge. I am I guess what people would refer to as a weekend warrior, not by choice, just a busy newly wed trying to keep a job. I've been tinkering in metal for about 18 months now, and it has become a real passion of mine. I have a small setup with a single burner propane forge I crafted, and a 106lb anvil, and a 42" belt grinder. While I enjoy welding and blacksmithing little trinkets, sculptures, and other forms of metal art, I've fallen hook, line, and sinker for the art of making blades. In the coming days I will begin to post some of my work, and I look forward to conversations with many of you, as well as any suggestions or critiques on how to improve my skills. For now, attached is my favorite to date, a small hidden tang grafting knife made from 1095 that I created for my dad, with a thuya burl handle. Once again, thank you to everyone in advance. Best Regards, Rick