-

Posts

159 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Jay.bro

-

Well I intend on teaching her the first aid stuff I learned in the Marines and what my grandpa taught me cause he was a logger and didn't believe in hospitals unless it was really bad I mean he had me use dental floss and a curved sewing needle to stitch up my own leg a long time ago and taught me starting fluid is basically ether it will stop most bleeding he taught me a lot and I plan on passing it down to her idk how to repair tendons but I can teach her basically the stuff he taught me and how to stabilize someone.

- 30 replies

-

- charcoal forge

- side blast

-

(and 1 more)

Tagged with:

-

Lol that sounds about right

- 30 replies

-

- charcoal forge

- side blast

-

(and 1 more)

Tagged with:

-

Well I'm just thinking aluminum cause it's light and I'm gonna experiment with turning my 55 drum forge into a foundry for aluminum and brass and maybe copper so I was thinking why not melt a bunch of cans and cast her an anvil and hammer with it so it's a small experimental thing I may melt some bullet casings and try that too for when she gets a little bigger but it's just an idea for now. I know how that goes charles. she's already picking up a lot of bad habits from tv idk why but she slaps and punches and if you tilt your head forward just slightly she will headbutt you really hard she chases our cat around hitting him with books and he's missing a leg already the bad habits are easy to learn but the good ones take a bit to set in.

- 30 replies

-

- charcoal forge

- side blast

-

(and 1 more)

Tagged with:

-

I may have to try that seeing as how my daughter has started copying me a little bit but she copies her mom a lot more than me and she curses every time she sneezes so I can hardly say it would only be my fault but I agree with you guys we don't need her cursing so I'll give the alternative curse words a go it'll take some getting used to though

- 30 replies

-

- charcoal forge

- side blast

-

(and 1 more)

Tagged with:

-

See I'm not so worried about the thing with it being bad but depending on what happens you know...anyways she's a tough little girl she rarely gets hurt but the sudden impact of stuff scares her a bit and I have a bit of a problem filtering my cursing when I work I don't throw tools often but I have been known to drop an atomic f bomb from time to time while working but mainly I don't want something to happen and her see blood spurting everywhere you know I get the cutting my hand and her seeing it get cleaned up I just don't want her to see the reason for a major er visit I'm actually considering making her a little hammer and anvil set once I get my foundry set up out of brass or aluminum just so she has something to play with since she now beats on our table with her toy hammer

- 30 replies

-

- charcoal forge

- side blast

-

(and 1 more)

Tagged with:

-

I probably did mess up the spring it doesn't stay locked so I may have to get a new spring it's a really small pair anyways it's just what I had and I only wear a glove on my non hammer hand unless I'm doing hot filing then I wear it on both. I have an old awning roller bar that looks like fairly high chromium steel I've seen a tong design that I can make out of it and they will suffice until I build a better pair I know it's kind of small stock for tongs but it's what I'm working with sonce drain out the tire iron didn't go as planned last time (burned steel). But if the weather permits ill link a video to this thread this weekend of the first fire were supposed to get some rain but hopefully not.

- 30 replies

-

- charcoal forge

- side blast

-

(and 1 more)

Tagged with:

-

Well I'm probably not gonna have her record the whole forging session just me tending the first fire in the new forge to see how it does and heating the first piece of metal in it to see how hot I get it. I don't have a set of tongs yet I broke my pair of vice grips last forging session by getting them too hot so now all I have at the moment is channel locks but I'm going to fix that very soon providing the weather allows it. I always wear my ppe. I don't have an apron yet but that is in the works. I don't actually grind anything so I don't use a face shield just safety glasses. I don't wear ear plugs since my anvil doesn't ring much at all and I have a pair of welding gloves I use when I'm handling longer stock and using my channel locks but that's all I really have besides my steel toes. I am extremely cautious while forging cause my 16 month old daughter loves watching me forge from a distance so I don't want her to see me get hurt.

- 30 replies

-

- charcoal forge

- side blast

-

(and 1 more)

Tagged with:

-

I may have my wife record me using it this weekend and upload a video of the initiatin fire into its life of forgehood

- 30 replies

-

- charcoal forge

- side blast

-

(and 1 more)

Tagged with:

-

Hey guys I finished my new jabod this weekend and it just dried up good today since it just rained here a lot last week and I dug in the mud to fill it up I need to adjust the tuyere height since its only about an inch above the bottom of the fire pot I used 2 bricks to make the fire pot since that's what I had and it seems adequate I haven't got to fire it up yet but this weekend I'm gonna get in some time with the forge. Let me know what you guys think. Oh the second pic has my first 55 bottom blast forge in the background. The brick is for size reference.

- 30 replies

-

- charcoal forge

- side blast

-

(and 1 more)

Tagged with:

-

Lol I figured I could test it on one and possibly build 2 jabod forges if it works great with the tile and make a trench box forge in the second one with it.

-

I actually didn't have the concern so much until I read through your jabod thread and seen where you mentioned smoke from under the forge isn't a good thing lol. That's where I came up with the idea of using the tiles we were cleaning out the storage room when I was reading through it and I seen the tiles and it came to me that those would keep me from punching through and if I did punch through I'd hear it break they are basically 1/4 inch thick tiles and I think 2 ft x 2 ft.

-

I'd imagine that would work great as a bottom for it to keep from punching through and probably reflect a little heat too

-

I have those too I was just trying to find a use for these we don't have tIle in our house and they were just here when we moved in and there's no use for them

-

I actually have a couple of ceramic tiles I appreciate planning on putting in the bottom of the box between the wood and dirt thinking it will work to keep me from punching through to the wood while I'm cleaning it

-

This vido was one where they used a plastic flowe pot I think the video said simple backyard foundry for melting aluminum cans and he used an empty fire extinguisher in the center it was an interesting video but he only used plaster of paris and I've read that mostly POP isn't what you wanna use

-

The main plan for the foundry was aluminum and brass or bronze maybe some copper eventually for a future project idea I seen a video of someone using a flower pot as a foundry but she is the one that suggested the 55 drum forge as one and I'll have to look into the bloomer idea

-

Honestly she loves Watchung me try to forge lol she's 26 weeks pregnant but she always has to listen to me talk about the forge and I told her I wanna build a small foundry months ago and she said a couple of days ago that since I am gonna build a new forge I could turn that into a foundry. As far as the new forge I have a table I'm not using that's about the right height and I have considered a more portable one our of a cat litter bucket

-

Thanks tp this was actually the reason I asked if I could be pushing too much air through it. I knew I wasn't blowing it out but at the same time I wasn't getting a ton of heat either. Thank you Charles I have decided on making a jabod forge seeing as how the forge I have needs modifications or I can keep it a bottom blast and have 2 different styles my wife mentioned turning the bottom blast into a form of foundry set up or blast furnace which I enjoy the thought of but much more research would be needed on that front. I will definitely try the hand pump seeing as how I was looking at finding the materials to make a box bellows

-

I was actually really happy the first time I used the forge I got it to a bright yellow orange and I felt very pleased with that seeing as how it was the first time I had done anything with the forge at all but I know I can use this experience to work on future projects

-

I have considered a conversion to a side blast but I was planning on building another forge as I got my beginner practice done with this one but I hadn't considered the breaking up the charcoal into smaller pieces I had searched and everything I had read was to add more air to make it hotter but it seems like more air was hurting me in this case I had kinda bent a piece of jack handle for a twist jack the other day into a coal rake by heating it as a short test of how well it heated and it achieved a nice yellow heat the first time using charcoal then I tried today and I was trying to see how hot I could get the steel with some tool steel and I know it wasn't anywhere near forge weld heat so I thought I'd ask. Thank you frosty

-

Hello all I seem to be having some problems with my charcoal 55 drum bottom blast forge. I can get the iron to an orange color almost yellow but I can't achieve a yellow/white color on the iron. I have been running my hair dryer on high with the turbo button pushed trying to get more air and I was wondering if it's possible that I could be pushing too much air into the forge or is it more likely that my hair dryer isn't pushing enough air?

-

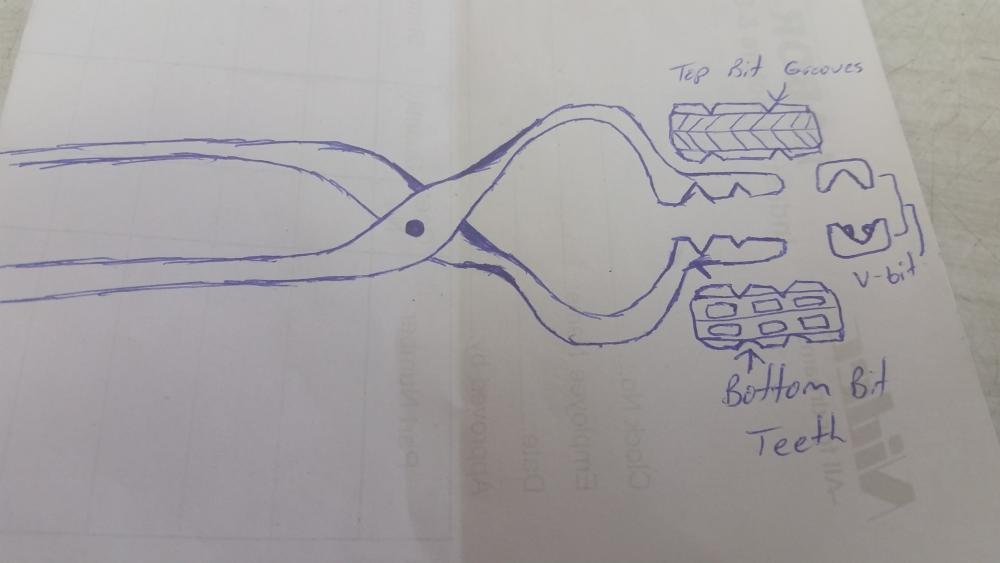

I like those I was actually thinking the cross slot on top and bottom though and make them different sizes on front and back so it can accept at least 3 sizes of stock. I was actually thinking that the grooves would assist with the heat loss into the tongs by creating spots where it doesn't touch the steel so less heat transference into the tongs from the work piece. Does the cross slot help with holding stock for scrolling?

-

Well this was just a idea I had seeing as how I see tons of threads on here about people wanting to know what the best set of tongs to make for versatility and I continuously read reply saying bolt tongs and the other half I read generally say wolf jaw so in my mind if the 2 designs could fuse then it would be a very good tool for people to start out with if someone sells them already I was more throwing my quick sketch out there as a reference for what I was talking about and some ideas I'd had for people to give feedback on for example the teeth on the bottom bit may be counterproductive and someone has tried it before and may save me an hour or so of filing those in or someone may say they never tried it and it inspires someone to make a similar version of their own. I was thinking more general use tongs though.

-

So I have been reading through a ton of tong threads and I have my material picked out and I have came across several discussions that refer to bolt and wolf jaw tongs as the 2 most universal tongs I have been wondering if anyone has tried to make a hybrid tong between the 2 and if so we're they a success or were there detriments to using them? I've attached a rough sketch of my idea if you guys wanna critique it and let me know what you think.