-

Posts

7 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

East TN

-

Interests

Custom trucks, beer, metal fabrication

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

Building my own power hammer

renaissance man replied to renaissance man's topic in Power Hammers, Treadle Hammers, Olivers

but like most videos on YouTube, there is no video that I could find at the time of him using it on metal. -

Building my own power hammer

renaissance man replied to renaissance man's topic in Power Hammers, Treadle Hammers, Olivers

With the red hammer build the builder used a 16 pound sledge head for his hammer. If I build that type of hammer I would definitely go for more weight. As far as the treadle hammer goes, that is very interesting and I might build that as well. Can't have enough tools right? That is a good point, and I half expected to get that many responses. I have started reading the thread but like you said there is a LOT of information. I will come back with either a better question or my decision. -

Hello I forge family, As I've previously stated I am an amateur blacksmith. I have a few projects under my belt. Since I started on this journey I've wanted to build a small power hammer, just to aid in the busy work of drawing out material and whatnot. I guess my question is which power hammer design does everyone prefer? I have included a few photos, I'm leaning towards the red hammer design but I'm also interested in the foot power design. I'm sure there's already a thread that covers these but I couldn't find it. Any help is grateful.

-

Beginner anvil

renaissance man replied to renaissance man's topic in Anvils, Swage Blocks, and Mandrels

I live in Morristown. After getting a piece of it cut into two smaller anvils with different horn sizes I think I'm not going to weld anything on top of it. After reading a lot about turning the rail straight up on its side I stumbled across an image of an anvil cut out of a piece of rail, welded to the top of a rail on its side. That's my next attempt. For now I'm going to use what I have. I'm learning as I go. Thank you for the advice! I was able to get the rail for free and cut at work for nothing. I know eventually I'll get a real anvil but I hope this will help me get started. -

So I'm sure this is gonna cause quite a stir, but please be gentle, I'm new to blacksmithing. I can't afford to buy an anvil right now, but I was able to obtain, legally, several pieces of railroad rail. As shown in the pictures I'm planning on cutting one piece in half to make two anvils as an experiment. I've read about people using a leaf spring and welding it on top for the flat and hardened surface, then throwing it in a fire to slowly heat up and then dropping in water to harden. I guess my question is, I also obtained a piece of steel they use to attach the rail to the tie. It has square holes already in it, and it the length of my anvil from the horn to the end of the face. Can I use this in place of the leaf spring? Later on I plan on cutting another piece in half and welding the two pieces together to form a wider anvil, with a piece of hardened steal welded on top. I forgot to mention I plan on using one of the square holes hanging off the back side of the anvil as a hardy hole. That way I don't have to drill any holes into the rail itself.

-

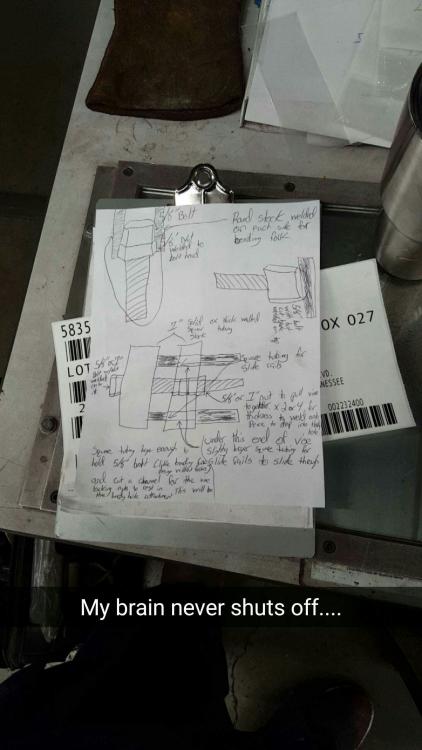

The drawings are very crude, but here are some of the things I'm planning. My anvil is a long piece of railroad rail attached to a 150 pound tree trunk, so I don't have a hardy hole. I was going to drill a 5/8s hole and weld a nut underneath, using 5/8 bolts for all the hardy hole tools. However I also obtained, legally, a piece of iron they use to hold the track to the railroad tie and the square holes in it are 5/8 also. This has me thinking of anchoring that plate on another stump and drilling a 1" wide hole under it for the hardy tools to fall into through the plate. I'm undecided on the direction I'm going right now. I forgot to mention I saw a guy on YouTube using a pair of vise grips welded to a plate and the plate was welded to a hardy hole piece which he used to hold his round stock while he worked it. I might try that first for the anvil, and the vice contraption on the hardy hole plate I mentioned earlier.

-

renaissance man changed their profile photo

-

I just became a member so please forgive the few year late response, but I don't currently have a vise and need something to hold while twisting smaller metal right now. I just drew up a hardy hole vise while at work that I will be making shortly. I would love to be able to look at the pictures previously posted for better references or design but unfortunately they won't load anymore. I'll try to upload pictures when I get mine compete.