brianstucker

-

Posts

140 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by brianstucker

-

-

I've been reading and studying Jim Batson's book. Instead of making a 24.5 ton press I want to build a 49 ton press.I have a question. If I use 2 cylinders. Would I have to double the Hp? Thanks

-

What kind of satanite coating?

-

Yes I put quick disconnects on them. I've got the small one painted. Still have to wire in the thermocouple. With the small fan on it it will roughly get to 1850 degrees. I could put a bigger blower on it and easily get to forge welding heat. But I'm gonna just leave it alone and strictly use it for just getting metal to temp to forge. And use the bigger one for forge welding.

-

Very nice.

-

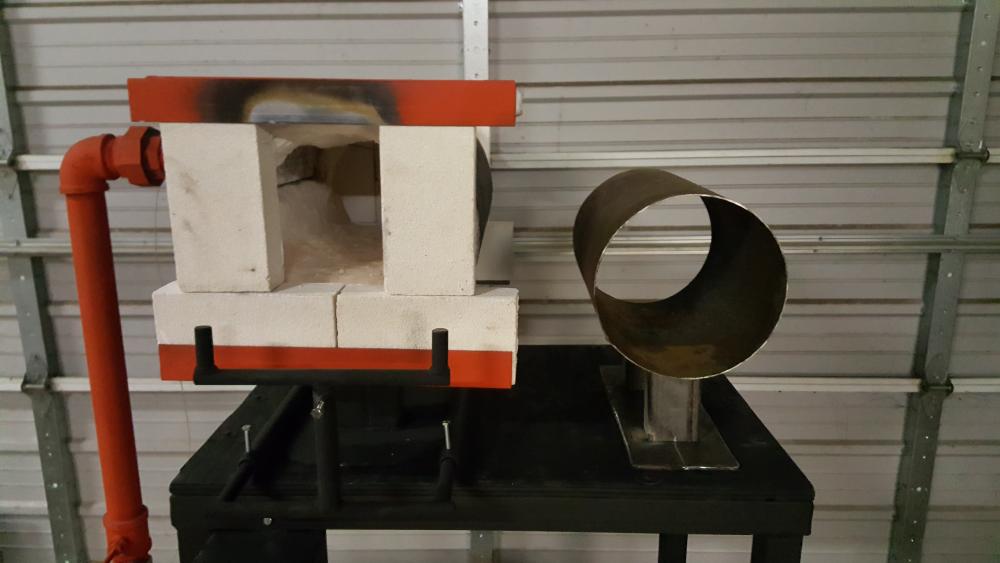

Here is Jr. He's running like a champ. Still have to coat the inside with the matrikote 90. And a few touch ups. The inside diameter is 5.5 inches. 15 inches long.

-

Just scored a 200gal propane tank from my propane guy. It was 250$. He's gonna come set it for me in the next day or so. I figured by the time I fiddle fart around with getting these smaller tanks and getting them filled. I won't have to worry about it. And plus he will come and fill it when I need it. We use propane in our house and pre buy it in the summer and its a lot cheaper.

I got the small forged with Kawool and rigidizer. Gonna line it with mizzou tomorrow. Looks like the ID will be around 5.5 inches. Sorry for the repost of the video.

-

-

I am using a 164 cfm blower from blacksmith depot. I am in the process of testing the small 11 hole ribbon burner. I think its getting a little too much propane. I used a 1/8 in bit on that mig tip. I think Im going down to 1/16th in on the mig tip. I got the air diffuser idea from some of these homade foundry burners. They are simple to make. I will take some pics of the one I build tomorrow.

-

-

I want the smaller forge for better fuel efficiency.

-

I also coated the firebrick with matrikote 90.

I'm also getting ready to get a 250 gal propane tank. So I don't have to mess with these bottles. I'll just get my propane guy to fill it up.

-

I just ordered 2 safety solenoids 1 for each forge.

-

I'm gonna put a safety solonied in my system. I just have to order them.

That matrikote 90 is also a hard coat but is is weak compared to the mortar. I coated the entire inside forge with 2 heavy coats. And matrikote is also helps retard flames.

It was a Long testing process with this set up. I feel confident with it. I tested the burner relentlessly. Must of had it apart and assembled 20 different times. I made it to where it can be totally disassembled accept for the cart I made.

-

I used an old 100lb propane bottle cut down to 21 inches for the forge body. The internal dimensions are 8.5 in tall and 9.5 inches wide. The pid I used is programmed to read temp. I think I got around 70$ into the homemade pyrometer. It is lined with 2in kawool . The bottom and sides is cast with mizzou. And it has a couple of heavy coats of matrikote 90 ac on it. It does great but goes through the propane. Im in the process of building a mini 11 hole version. I have already cast the the burner head. And almost have the forge body done. It was already a planned build. Its gonna go next to the big mamma version.

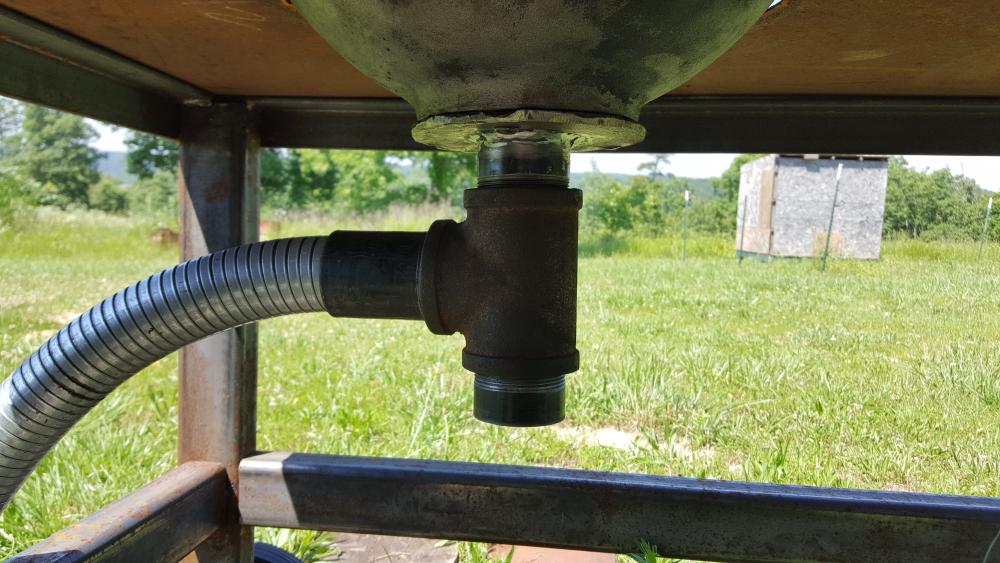

The propane delivery orfiace is a reducing T to accept a 1/8th in schedule 80 pipe nipple. The pipe nipple it tapped to accept a mig tip. I dont recall the tap size. The mig tip is drilled to a 5/64ths. I will take photos of the next one I do.

-

Here is the finished forge.

-

-

2 hours ago, littleblacksmith said:

did you paint it?

Littleblacksmith

No. I just put some pb blaster on it. It's a penetrating oil. I popped that nut out of the hardy hole. And it also cuts rust.

-

-

-

10 minutes ago, littleblacksmith said:

I told you you would find one! Aren't you glad you didn't buy any of the other ones you thought about getting? I'm almost as exited as you are! Now get hammering!

Littleblacksmith

Thanks Lil blacksmith. I feel like I was a kid on Christmas morning. I'm working this week. But I'm gonna try to finish my forge and get started this weekend.

-

-

I'm gonna meet with him Tuesday. I'll let you know how it goes.

-

30 minutes ago, Frosty said:

Making a counter offer is hardly "beating the bloke down on the price" In the real world it's just saying, "I'm not a sucker." And don't tell me about hard to find blacksmithing tools, around here that old beauty would've been sold before the ink dried on the craigslist add.

Weld beads on the side don't mean a thing. The nut driven into the hardy might be an issue or are you good with a cutting torch? Even with one of my eyes wonky I could zip that out without warming the face.

That's a good price but don't be bashful about making a counter offer in person and keep on smiling. Ever do a rebound test? A ball bearing or small ball pein hammer will tell a lot about it. I recently replaced the 3/8" ball bearing in my pocket for a 1/2" one I got in a bucket at a yard sale last summer. No need for a really big one I just find the larger ones easier to find when they take a wild bounce.

Frosty The Lucky.

I've never done the rebound test on an actual anvil. But I got a piece of die hardened steel I'm turning into an anvil and done a rebound test on that with a a ball peen hammer. I am new to this just trying to learn the right way. And actually he wanted 400$ for it and I got him down to 350$ over the phone. I buy sell and trade all the time. It's just part of the game. Some people enjoy a little haggling back and forth. That just makes it more fun. I expect people to throw a counter offer back at me. It doesn't offend me if I'm selling or buying. Where is the best place to find ball bearings?

-

I'll be working over the road for the next couple of weeks. The guy is no hurry to sell it. I can't meet with him for at least a couple of weeks. He said it wasn't going anywhere. So as soon as I can meet with him. I'm gonna go check it out and pick it up.

Forge Press Question?

in Presses

Posted

I appreciate the info. Does anybody know what size pumps are on these built by Carolina Knives,