brianstucker

-

Posts

140 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by brianstucker

-

-

I will. It's unbelievable how on the ball these Chinese fellas are. They answer e-mails promptly and they sincerely want your business. Ive got bids from several different places right now. . I'm going to do this in 2-3 months depending on funds. I will keep you posted.

-

I'm gonna roll the dice. Ive actually lost more money in a poker game. It stings for a while. But you will eventually get over it. As far as the quality of the motors. I' m willing to take a chance. To be honest I hate buying Chinese.

-

Im gonna get a couple more quotes from different company's there. And do some mo research.

-

Thanks. That thread Chinese Hammer Differences is a good read.

On 3/16/2017 at 9:07 AM, CMS3900 said:Your doing your research man, and its smart to do. I had quoted a 165 from TZ Rufna, and found they had a similar price.

This is not the new Anyang design. They have that new hammer patented and will not sell to an individual.

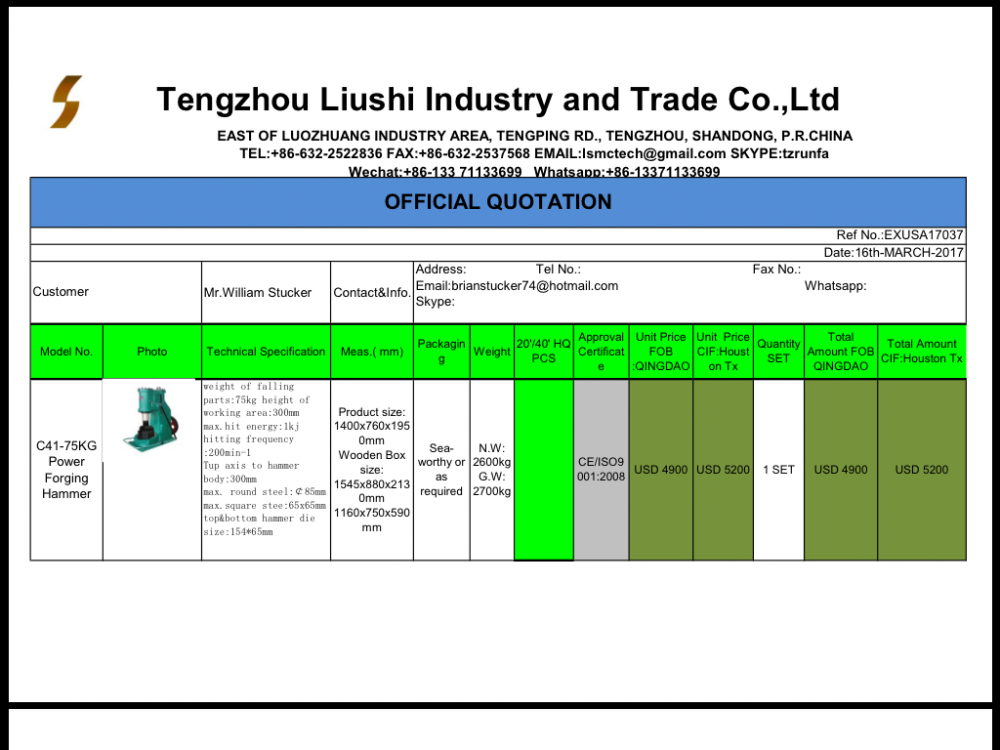

The hammer above has a 13 month warranty. But coming all the way from China I kind of expect the rear view mirror warranty. It does come with motor and all the belts. And everything to hook it up. I am getting a 40kg quote. I got a quote for a 150kg and a 75kg. These people are on the ball. Answering questions. Tempering dies to a certain Rockwell Hardness. Choice of die material used. Im thinking of getting a couple of holes drilled in my bottom dies. To set bolt on jigs. It will be a while before I pull the trigger. These quotes are good til July 15th.

-

-

Has anybody directly ordered from China through Ailbaba? If so how was your experience. Thx

-

I've been blacksmithing long enough to know if I want to get anything serious done I'm gonna need a Power Hammer. Any Anyang owners here? Would like some pro's and con's. Thank You.

-

That's nice bro.

-

On March 8, 2017 at 7:04 PM, tdriack said:

I can't seem to find my notes / calculations at the moment - but it was calculated within the ranges everyone has suggested - 1-2" a sec. Obviously the single ram option will be way faster than the 2 in parallel - when it's finished I'll be able to give more than theory calculations.

BeaverNZ as for hoses and returns ... I'll be using size 16 hydraulic hoses that are tugboat steering ram used/ scrap surplus hoses (but still new and in good shape to most) - I'm pretty sure that a 1" will cover my return speeds from my experiences.

Once I finish my build (hopefully over the next few months - if work/free time allows) I'll post a new thread of my build.

I interested to see it. I'm gonna start one at the end of summer. Pretty much the same set up as your working on. I was gonna build a hammer also. But the more I read. I want to do it right the first time. I don't want to constantly be fixing the silly thing o get it to work. I've got a line on an good used Anyang 88.

-

Thanks LB

-

Hey lil blacksmith, If you purchase this online course can you watch it as many times as you want? How does it work? Thanks

-

Nice

-

On December 31, 2016 at 11:21 AM, tdriack said:

I'm building a press currently - although time is limited so it's going slow..... Here's my thoughts:

I'm aiming for lower noise after reading a ton of links and watching videos with 3450 rpm motors screaming in the background.

My build is using a 7.5 hp 1750 rpm single phase motor with a 28gpm two stage pump (since it will be running at half speed to give me close to 14gpm). I'll be using two 5" x 16" rams in parallel - it was way cheaper to go with two 5" rams instead of a single 6". I will be building a H frame with the rams on the bottom and there will be 3 clevis pin holes - 2 for using double rams and one centered for using a single ram (if I decide I want more speed with 1 ram and and a little less tonnage).

What kind of speed will you get with that setup? Ty

-

Enjoyed the build.

-

-

2 hours ago, swedefiddle said:

Good Morning,

Most shafting is about 1045. I looks like you didn't finish the Hammer face, you need radius edges and NOT a flat face (unless you are making a Flatter). You will learn how to make Hammers after you have a bunch. Using mystery Metal is a waste of your time, equipment and energy.

Be careful when using 4130, 4140, 4330, 4340. Look up in the Heat Treating Data for Temper temperatures. They are "Blue Brittle"!! When the data sheets say to not temper to a certain temperature, there is a reason.

Neil

I appreciate the advice. And I agree with you. I was just researching radiusing hammer faces. I thought I had a radius on it. But mine is more like a bevel with sharp edges. I am going to find some good steel for hammers. I really hate mystery steel but it was what I had on hand.

-

I spark tested the metal. It's some kind of high carbon steel. Then I file tested it after the quench. The file skated right off the metal. What's a good hammer making steel?

1 hour ago, Lionel h said:Looks good , I want to make one myself ,I'm gonna use an axle for mine . How hard was it to drift the handle hole, I've never tried to drift a hole in that thick of steel?

I drilled a couple of starter holes first. And connected them with a die grinder. That made it easier. But it still was a chore. I also made a drift out of some other mystery high carbon steel.

-

I'm only getting around 50% rebound. I heated the whole head to non magnetic. Quenched in oil. Then tempered 2 cycles ar 425. Its mystery steel. It's a shaft from an old sawmill. The part that holds the circular blade. Is that normal for a hammer of this type or should it rebound more? It does work. I used it on a blade I'm forging. There is no dents or chipping to the face. Thanks in advance.

-

-

Very nice. Enjoy watching the build.

-

What single stage pump could I run on with a 10 hp 1700-1800 rpm's. And get descent speed out of the ram. Maybe 1.5-2 ips. Thanks.

-

From what I understand you have to have an air compressor putting out a minimum of at least 17cfm. I bought the plans. I like the design for simplicity. But I don't want to spend 1500$ on an air compressor.

-

Get the mark 2 design version.

-

Very nice.

Nimba anvil

in Anvils, Swage Blocks, and Mandrels

Posted

I would love to have that 450lb Gladiator. I have dreams about that one.