-

Posts

1,966 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Mark Ling

-

-

he wants something that he can display. not so much a tool.

littleblacksmith

-

On 2/13/2016 at 11:51 PM, Scrambler82 said:

I like the looks of a Vulcan Anvil !

It is a cast iron with a steel plate but I still like the looks.

Tap around on the top plate, listen for any thuds, may indicate a top plate that isn't secured.

If it sounds all the same, it could still have life in it !

I agree it reminds me of the older London pattern anvils that were "stubbier" . really good price that you paid for it. it will work heck I used a sledge hammer head as my first "anvil"

Littleblacksmith

-

my first anvil was a sledge hammer head, then a railroadplate, then a piece if railroad track, then I borrowed an anvil from a farrier I know, and finally I found a hundered pound Trenton anvil and is what I currently use.

Littleblacksmith

-

I cant really help

but was just wondering how much you paid for them? was it all four in the pic that you bought.

but was just wondering how much you paid for them? was it all four in the pic that you bought.

littleblacksmith

-

so I know someone who has a ball peen hammer that he wants me to "repurpose" or make something out of it for him. I told him that I could make a tomahawk/or hatchet out of it, but he said that he wants something more decorative or something he can use daily and be able to say " yea, this was my fathers". got any ideas of what I could make. pics would be great.

thanks in advance,

Littleblacksmith

-

wont be long till you make a 4th!

-

sounds good!

Littleblacksmith

-

definitely one of the more quality tool racks that I've seen. great job!

Littleblacksmith

-

so why use wrought iron. I mean, it sounds like its more difficult/frustrating than mild steel (splits, frays, hard to weld, etc) is it just preference? why use it?

Littleblacksmith

-

That's a "sharp"

looking knife.

looking knife.

Littleblacksith

-

I know this isn't what the thread is about, but the anvil stand you might want to build it up around we're the feet are going to be so that it doesn't slide/bounce around. The side blast looks really good. I can't imaging how much welding and grinding that must have taken. Look nice,

Littleblacksith

-

that's a beautiful handle-better than any ive seen in any hardware store. like the design of the head. wow, amazing!

Littleblacksmith

-

I love when people go with the "rustic" historic look in their shop. my dream shop.

Littleblacksmith

-

The "extended" horn would be helpful for making small curves/circles.very interesting-I like it!

Littleblacksith

-

why didny you just use the body frome the Chinese junk ones and just switch the moters ? im sure that its an obviose reason, but that im to "dumb" to realize it right now.

Littleblacksmith

-

meant to say roof-think yall knew what I meant. this isnt gano make any sense 'cause its going to merge my posts.

Littleblacksmith

never mind it didnt

-

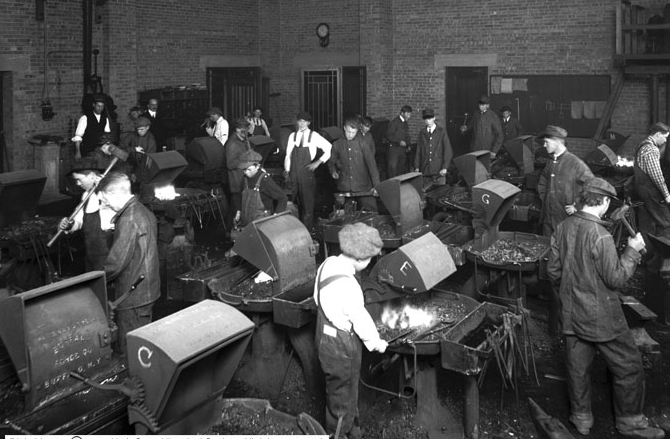

it said they were in a high school class- mybe a shop class

Littleblacksmith

quick question, where does all of the smoke go- I mean theirs no pipe going up out the roop

-

found a picture on google desmato of the forge in action- actually quite a bit

-

id be worried that the haybales might catch on fire. that would be pretty bad

Littleblacksmith

-

id hang it up on my wall!

littleblacksmith

-

its not perfect but close to being. I know that I would be pleased to own it. did you just fold over the socket or did you also weld it. forge welded or electric? sounds like a challenging project not to completely melt it if you forge welded it.

Littleblacksmith

-

another POSSIBLE problem could be if a coal falls on the nylon strap than it might burn through it and everything comes crashing down-that would be a bad day.

Littleblacksmith

-

LOL Charles, Bhutton, looks very portable and simple. like the others are saying a side draft is better than an overhead hood, because the hood doesn't create as much of a draft typically, and if there is a breeze than the hood is almost useless. But if your forging outside than its not as neccisary to have a hood/side draft but it does/can help.

Littleblacksmith

-

if you could find a brake roder than that would probably be shallower. one thing that you can also do to make your fire smaller is to wet the area you don't want burning with some water. Just a couple suggestions.

Littleblacksmith

So i got this 2.6 kg cross peen

in Hand Hammers

Posted

that's a big hammer. very unique.

Littleblacksmith