-

Posts

69 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by c.baum

-

@Glenn @swedefiddle Of course it's usually a matter of time, practice and patience. But you know, sometimes you're in a blind alley (is that the correct term?) and have to return to the beginning. See, it's sometimes really frustrating making really good tools and so on but not being able to make simple nails. And then you need a push into the right direction. And that's what this forum gave me thanks for that!

-

@ausfire cooling the nail in the header is a good hint. Thanks! @ThomasPowers Touching the edge of the pitchel hole. Could have find out that too @Glenn Thanks for the layout. It's the first time to see a nail header with a hour glass shaped hole. The problem is that i have taught my self everything about blacksmithing by watching videos, reading books and asking people. And most of the nail header tutorials tell to taper the hole from the bottom. I even saw a blacksmith making nails in an old hinge with a square hole cause he had no nail header at his fingertips. That's why i'm surprised but i will definitely try it. Thank you all so much for your help! I'll keep you up to date about my nail making progress.

-

Hello Community, I badly need some help! I'm at my wit's end. I already made so many things successfully. Tongs... Knifes... Axes in different sizes... And many other tools and things. But I'm currently not able to make a simple nail! I made several nail headers, drilled holes through 'em an drifted them to a square cross section tapered to the bottom side. I shouldered down the stock on two sides and draw out the tip of the nail. But every time i forge out the head, it's not centered. No matter what i try to move the metal in a direction.Also after "forming the head" i turn the nail header and the complete nail is crooked or just won't slip out the header with out brutal force. If there's one nail (out of ten) satisfying my image of a nail, it deforms while hammering into wood. I've got the feeling that i'm kind of deadlocked. So I want to start from the beginning. Are there any helpful hints about what i can do better? I would be very pleased if someone could help me find my way to a reproducible nail. P.S.: I tried to use the search function, but the search engine is not that helpful.

-

Nice work! And if it does the job every thing is fine. I made my flatter the "blacksmiths way", that means forging down a large piece of steel at one end, putting it into the swage plate and smacking the xxxx out of it with a sledge hammer. Works fine too and took me less than 1,5h, punching the handle hole included. Mod Note:Your images have been reworked from over 4 megs to less than 100K in size.

-

I wish I could afford to make charcoal

c.baum replied to Glenn's topic in Solid Fuels: Coal, Coke, Charcoal, Wood, etc

that's really a amazing video. All you need is some "mud", a bit of fibers for stabilizing the mud and wood. The videos shows that you definitely do not need much effort to make charcoal. I prefer a little bit more modern way with an old barrel using the TLUD process too. -

"...oh, the tire's got quite little air ... but only on the bottom..." When i got my power hammer (75kg ram, 3.5 tons in total) i had the same experience. I expected not more than 1.5 ton, so you can imagine how underdesigned the equipment was I'm looking forward to it! Just contact me when you're in Germany! I'll post a pic of the anvil, unfortunately i do not have any picture of my self engineered construct. I agree, i'm in contact with Refflinghaus, and he has never seen such an Anvil...

-

Uff, i do not have any information about the manufacturer since the anvil might be made in 1975 or so. The only mark is the 400 for the weight. I don't think it's a Refflinghaus, i think it's "just" a mass product from a soviet or GDR-mill. It's not that easy to read if it is meant in a sarcastic way or not, especially when just that one sentence is quoted. First thing i thought when i read the post was "oh, now they all think that you where pregnant with the anvil"

-

did i write anything wrong (i really have to improve my english skills)?

-

nice issue. Had to move my 881lb anvil when i got him. Never imagined how hard that could be. After he had been dumped on my yard i moved him with a chain pull into place, i built the stand, lifted him with a timbered frame and the chain pull, put the stand under the anvil and lowered the anvil. The rest of the shop was built around the anvil. p.s.: yes, i'm talking about my anvil as a person cause he's even got a name as all my heavy tools have one

-

-

What did you do in the shop today?

c.baum replied to Mark Ling's topic in Blacksmithing, General Discussion

a pair of goose neck tongs, made of AISI 6150. Not that bad in my eyes. But there's always something that could be done better. -

Show me your anvil stands

c.baum replied to pkrankow's topic in Stands for Anvils, Swage Blocks, etc

Yes it is. in german it is "steirische Form" (styrian shape?). Largest anvil you can by on the market as far as i know. It's been used in a smithy in a salt mine where usually tools were made. See the mentioned thread for the story how it followed me home (i wish it was that easy ). oh, there are some tiny ones. seems it has been used as a cutting and welding table. And the corner on the far side has a lot of chips. the base is about 730 x 470mm. The ties are about 230x150mm, but a good friend dressed them up on the planing bench. Don't know the original dimensions. engineer -

Show me your anvil stands

c.baum replied to pkrankow's topic in Stands for Anvils, Swage Blocks, etc

Do you need any specific information? The face is about 195mmx890mm incl. horn, hardy 44x44mm. I'll post a photo. -

Show me your anvil stands

c.baum replied to pkrankow's topic in Stands for Anvils, Swage Blocks, etc

That's what i mean. The beauty weighs 400kg (about 882 lb). It's been quite a challenge to get it on the stand -

Show me your anvil stands

c.baum replied to pkrankow's topic in Stands for Anvils, Swage Blocks, etc

Made of old crossties (i hope, that's the correct word for it). I added some layers of tar paper between anvil and stand. Due to the size of the anvil i don't need any extra tool rack or so On the right side you can see the support for my hold down. -

Thx! My son is literally the best thing i ever made

-

Hi folks, i'm so sorry that i lost sight of this topic, but i've been in parental leave so i spend the time with my son. I hope you understand that. At first, many thanks for the links! Many nice ideas. Secondly: I've attached a picture of my current DIY dies. They work really fine for me. On the pic you see the 25mm radius fullering set. I use this set for "aggressive" drawing or large fullering. The base is a simple 10mm mild steel plate bent around the original die, installed with four M12 bolts. This is the first set i made, so i tried to make the bending easier by fullering the lines in the bend. It worked fine for the bending job, but unfortunately this caused the plate being bent open when fastening the bolts. So my next plates will be bend without the fuller. I also had the idea to make the plates of spring steel to prevent them from opening too. Further die shapes are planed too. The first set of 75mm radius dies is already made and waits to been mounted on the base plate. Smaller fullering dies like 15mm radius and axe dies are planed too. I'll keep you informed!! p.s.: one the pic you can also see the mounting tool for holding my spacers.

-

i really like the idea of the flip over spacers

-

tire hammer die heat treatment

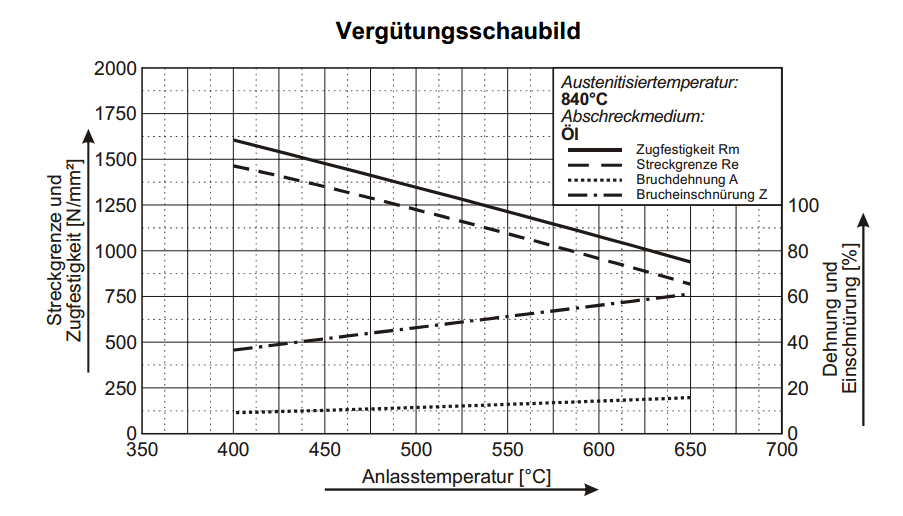

c.baum replied to canada goose's topic in Heat Treating, general discussion

That's exactly what i meant. But you can't say that every steel has to bee hardened slightly over Curie temperature and tempered at 200°C/400°F. The temps differ among the steel types and also depend on what you want to use it for. So the steel data sheet always should be consulted. E.g. spring steels become pretty hard when tempered at 200°C, usable for rough working-knives. But if you want to use it for a spring you need a much more complex tempering. -

tire hammer die heat treatment

c.baum replied to canada goose's topic in Heat Treating, general discussion

-

tire hammer die heat treatment

c.baum replied to canada goose's topic in Heat Treating, general discussion

of course the kitchen oven didn't reach 400°C/752°F (looking at the color something about 300°C/572°F). I just wanted to say that this worked though (165 lb power hammer dies). That's what i meant saying that this steel pardons a lot of mistreatment. 400°C/752°F is what the steel data sheet says to be the minimum temp. -

continuous cooling transformation diagram

c.baum replied to c.baum's topic in Heat Treating, general discussion

Of course Leidenfrost is a additional factor. But in my eyes even moving the tool in the quenching medium will show different cooling speeds at different diameters, not to mention the warming of the medium resulting a alteration of the cooling speed... -

tire hammer die heat treatment

c.baum replied to canada goose's topic in Heat Treating, general discussion

nice hint, unfortunately not available, neither at amazon UK nor amazon DE. -

that's an interesting statement. Which dimensions should the spring have at its cross-sectional area?I could imagine that the spring needs to be very very thin to support the movement of the top tool. 5mm thickness might be almost too thick in my eyes.

-

Hi Alan, thanks for your post! I've got a similar system to mount my spacers (pics following, thought I had some on my phone..). I already thought about using the spring fullers often shown in several post. But don't they have just exactly one point (equals one distance) where the faces are exactly parallel?! Yeah, seems to be a general problem. Many interesting posts lost most of the pics.