wolfshieldrx

-

Posts

447 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by wolfshieldrx

-

-

-

Ridgewayforge: Thanks guy! A couple years ago my son graduated from college and we paid off our house. That's when the finest woman who ever lived said "Build that blacksmith shop you've been yacking about...". Nothing fancy. 4x4 posts sided with T-111. Dirt floor. Tin roof. I built a brick forge around a centaur forge cast iron pot. Champion 400 blower. 12 X 12 feet of solitude nestled in a wooded corner of our little half-acre.

Glad you liked it. I'll see if i can find some pix of the not-so-neat interior. Bart -

Almost, sorta, kind of like this?

Bart -

Trip...

1/4 square for the sconce. Candle cups are copper water pipe split and opened up and are about 2 inches in diameter. The trivet is 1/4 inch round stock. Thanks for looking. -

Forged a pair of box jaw (hope thats what they're called) tongs and a little punch. Tongs are forged from 1/2 inch square stock. Punch from a tire tool. Used the punch to make holes for rivet in tongs. Thanks for looking...comments encouraged...bart

-

A friend of mine has a junk removal business. He was driving past yesterday, saw me working outside and stopped. He was on his way to the scrap yard to drop off a load, but asked me if I had any use for this odd vise before he scrapped it.

I don't really know anything about it, but its obviously meant for sheet metal / thin plate.

The jaws are 9" wide, but only open 1/4". It was free, and bound for the scrap, so I'm sure I can find a use for it.

Dont try to clamp anything "too" thick. If you do, you run the risk of cracking it since cast iron does'nt have much "give". (Dont ask me how I know this... :unsure: bart) -

I remember reading somewhere (here?) that the crank handle should be at shoulder height at its highest point. Thats how I installed mine and it seems to work well that way. However, as one of the other posters pointed out, it may be a very personal subjective thing, so that height may need to be tweaked a bit. bart

-

I like the lamp, and the hammer. Did you forge the head of the spike into the ball on the hammer?

Thanks on both accounts! Forging the head of the spike into the head of the hammer would seem the logical approach, right? But I had difficulties when I tried that...folding, quilting, cold shuts, etc. In the end, I just cut the head off, upset the end. Then forged a ball on the end. The spike was held in the vise while I shaped the head. Hope that made sense. bart -

I decided to make a dedicated hammer for sinking lamps, candle cups, etc into my swage block:

Made from HC railroad spike...comments encouraged. Bart -

Made another today :-)

Thanks for all the comments! Bart -

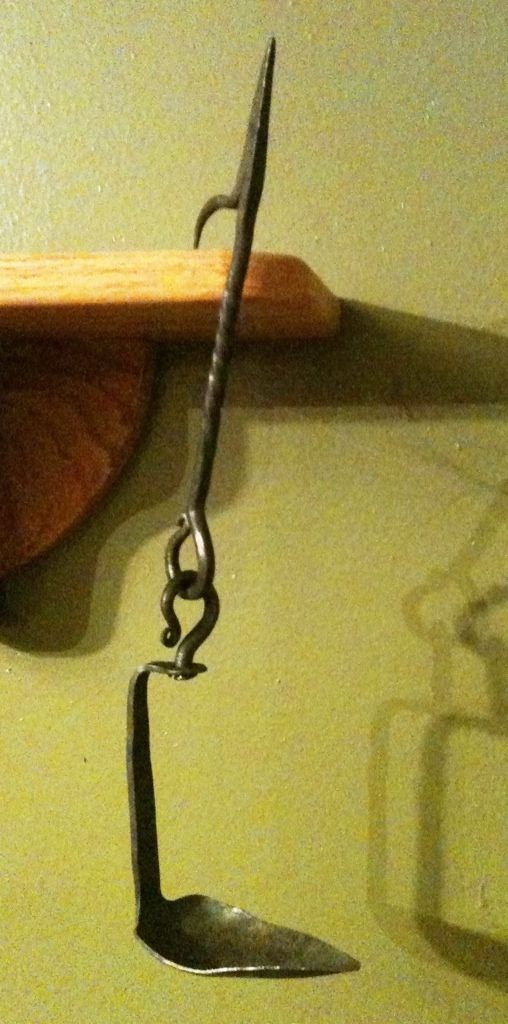

The pan is filled with bacon grease, animal tallow, or wax. A wick, usually made of rolled cotton cloth or string, is rubbed with the fuel and placed in the pan. When the fuse is lit, the fuel is liquefied, and as it burns, more is drawn up from the reservoir through capillary action.

What he said :-) bart -

I absolutely love this kind of knife. Looks great! bart

-

Looks great! Head and sholders above my first tongs. Keep making them...each set gets a little better. bart

-

Hey! I like that trivet;will it scratch wooden tables ?

Did you rivet the bowls on the wall sconce?

Thanks for sharing.

The "legs" are just rivet heads. I backed them up when peening the top side so they are pretty smooth, but dont know if they will scratch wood?? The bowls are riveted using 3/32 copper rod. By the way, the sconce is larger than it looks in the picture...weird camera angle made my thumb look huge! Thanks for looking guys...bart -

Thanks for looking. Comments encouraged. Bart -

Nice lamp whatever it's called Bart. I'd make Deb one but I get all antsy with something like that burning in the house, earthquakes aren't uncommon at all. Still. . .

Yeah, dont like open flames outside the forge or campfire...wife is using one of those battery powered led tea lights in hers. A little of the old...a little of the new i guess! Bart

Frosty The Lucky. -

Thanx for the comments! I've not tried it with grease. Wife using a candle in it. Glen: I'm no expert but from what I've read a betty (english corruption for german word for "better") lamp has a cover. Thus it is a "better" lamp than the open crusie lamp. Have also seen open top lamp called a "slut" lamp. Slut is an old word for mud. Makes sense when you think of what the mixture of various animal fats, waxes and oils being burned probably looked like!

-

I made a little grease lamp yesterday. Dont think i got the proportions just right but i'm pleased with my first try. Plus my wife likes it!

Thanks for looking. Comments encouraged. Bart -

Thanx guys. Gonna b there mon-wed next week. Been there before. Thought there might b something i missed. Bart

-

Takin a lil trip with my wife to Pigeon Forge/Gatlinberg next week. Any must-see blacksmith sites in area? Thanks. Bart

-

Hay rake tooth/tine. Thanks for looking! Bart

-

I thought this one turned out particularly well:

Thanks for looking...bart -

Just finished restoring this drill. Completely disassembled, replaced bearings, painted and mounted on a nice board. I think it is the smallest one Buffalo made so is portable. It can be held in a vise ir clamped to a bench usung the angle-iron bracket i mounted on the back of the board. All in all a really sweet little drill. I plan on using it at demos.

-

I am just starting out making friction folders and this is so beautiful I could weep with envy. Please tell me how you do the brass or perhaps you could post a diagrammatic sketch? I don't sell BTW. So if I imitate it would be sheer flattery.

Thanks for the encouraging words! Just my second friction folder and was kind of a seat-of-the-pants project. Brass liners were cut to rough shape with fret saw then riveted to bolsters. Next the liners/bolsters were rivet to the scale material. Finally the whole shebang was riveted together and filed/sanded to shape. Hope this helps. bart

Small smithy plans?

in Building, Designing a Shop

Posted

Inside pictures as promised:

Hasp and staple locking the door:

...holding the door open:

...looking into my mess:

Clockwise starting at the left as you enter:

125 pound columbian anvil:

Post drills, small Millers Falls for up to 1/4 inch, buffalo for larger holes:

Thanks for looking. Questions and/or comments encouraged.

Site administrator: feel free to edit and or delete any of this if pix are too large, etc. bart