-

Posts

50 -

Joined

-

Last visited

-

Well if I want to have forge welding heat at my altitude then that’s kind of what I have to have. Trust me I’ve tried xxxx near every kind of burner. You have a naturally aspirated ribbon burner? How does that work? Do you have any pictures? Because that sounds very interesting?

-

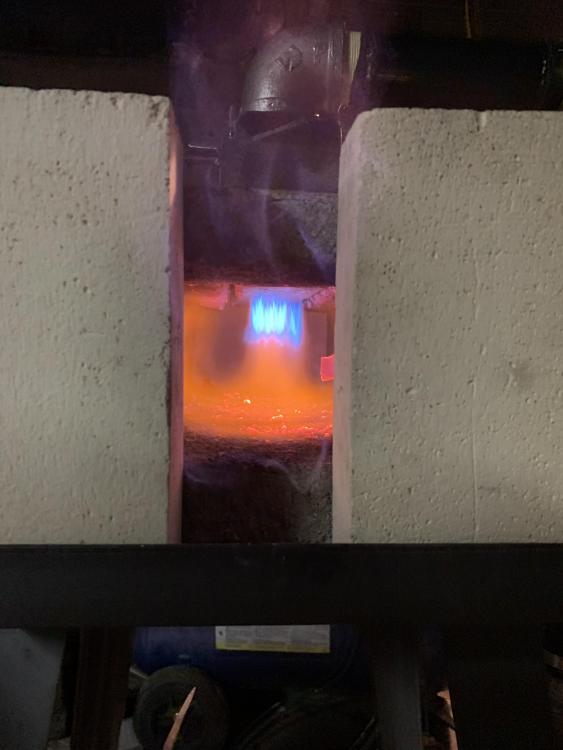

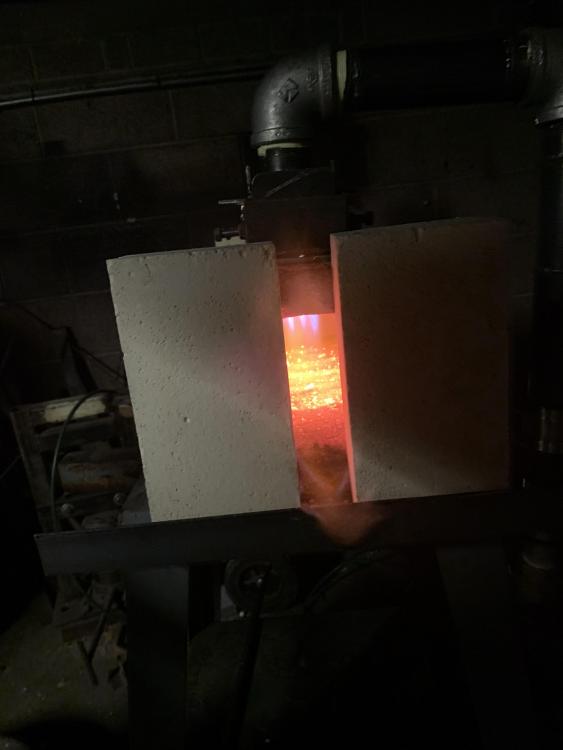

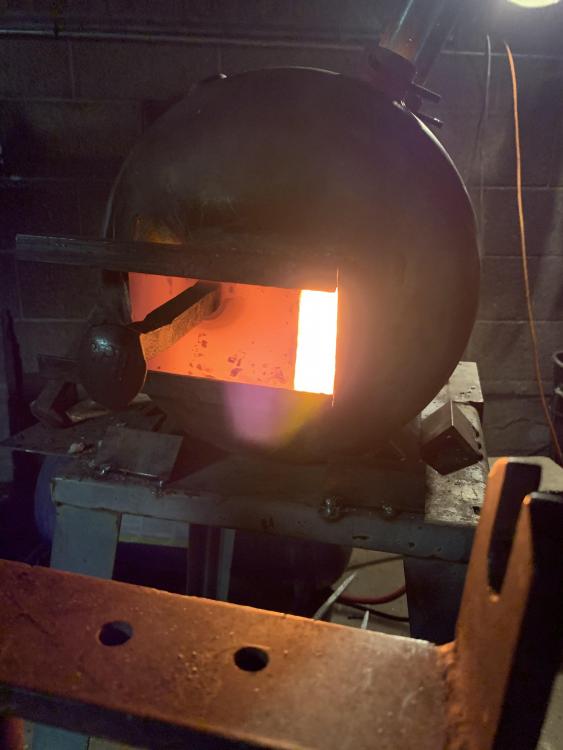

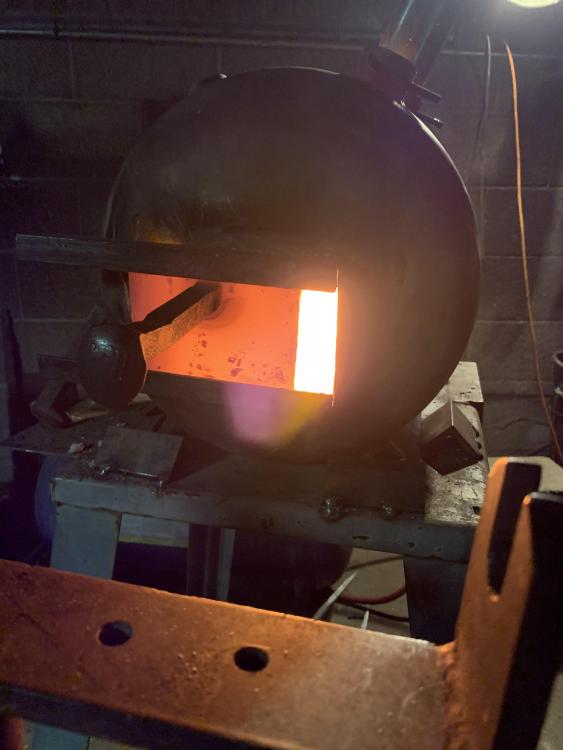

I was happily forging away in my new ribbon burner forge and as I was working all the sudden my forge went POOF! I need to say it scared the xxxx out of me. I tried to adjust a little bit and it did it again a couple more times almost back to back. I should everything down immediately and got on this forum to find out what that could be. I know one thing I do not want to get blown up. Here is a picture of my set up. Chris

-

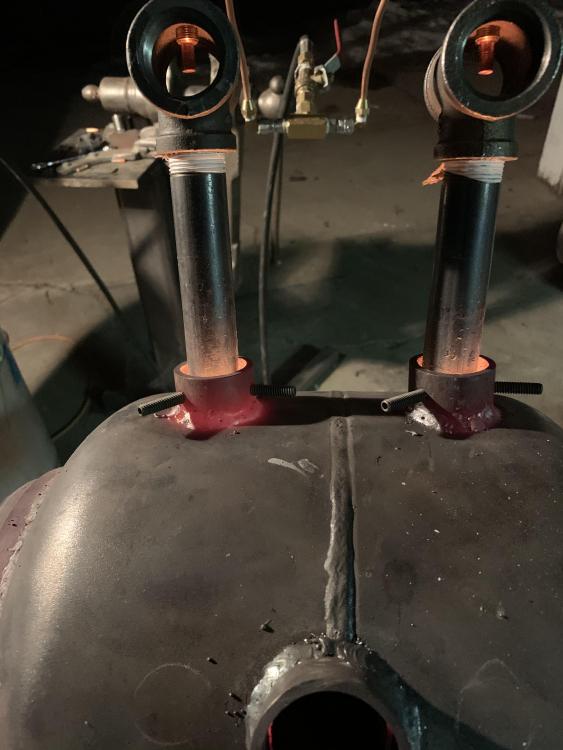

Ya know, between me and you, I broke the burner because of the bolts. As I was trying to put the plumbing together I thought I had the set screws tight ( I did) and the burner wouldn't move. I'm pretty sure it did push on the side cracking the bond. It just fell right out of the burner body. Thanks for the advice. I will do that. Hopefully the tabs that I have on there will be good but I know that the metal should absolutely not protrude into the forge body.

-

Frosty, It is basically Mizzou 3000. The Blacksmith and Farrier supply shop that I get alot of my supplies fro sells 55lb bags. I have experience using this refractory as I've had great results in the past. I'm just basically wanting to know if I would crack my burner if I didn't let it cure for the 3 days recommended in the plans for the ribbon burner plans that I printed up from Pine Ridge Burners. Honestly , I don't think I want to go off from the directions. They are written as such for a reason and I don't want any issues with this burner. I was just being impatient. The thing is, The refractory used for the burner is 3" thick so curing time is critical. Here are a few pics of my progress. That burner broke though. I dropped it. Oops Number 2. Lets not brake this one Chris...

-

chris freeman changed their profile photo

-

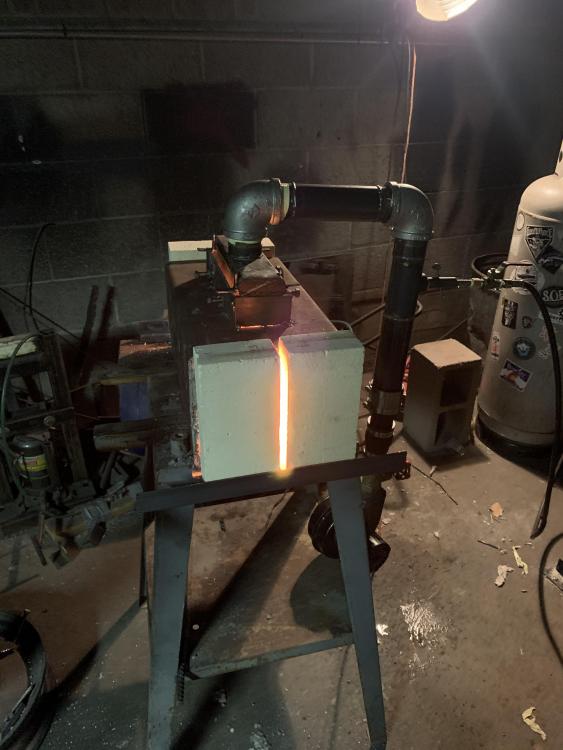

So I built a new forge from scratch. It's a ribbon burner forge and everything has gone smooth. Except the fact that I broke my burner as I was assembling the last tube and just about to fire up. Anyway, I have been firing the kao-wool & refractory floor, walls and ceiling every night after letting sit for 6- 8 hours in my oven starting at 195 degrees for 3 hours and then 300 for 3 hours. Of course that has only been 1/2" of cement too. I am curious to know if anyone has fired a ribbon burner after letting sit for less than 3 days. Yes I'm impatient. Especially after almost being done once. I was wondering how long it would actually take for 3 inches to set up and be ready for firing. I'm assuming 24 hours per inch, but has anyone done it sooner? Chris

-

Honestly It seems that I’ve tried every variation and modification and nothing seems to work. It’s seriously throwing me for a loop. I’m gonna go over everything one more time and like you said take notes and see if I can figure it out. Very frustrating. I’ll get it though.

-

It’s wool with refractory I apologize for sounding and acting to clueless about all of this. This is the first time I’ve built, ran or even owned an NA forge. It seems to me that I’ve tried everything but obviously I haven’t. Obviously I keep changing everything up all at once. Thanks for the help. Merry Christmas Chris

-

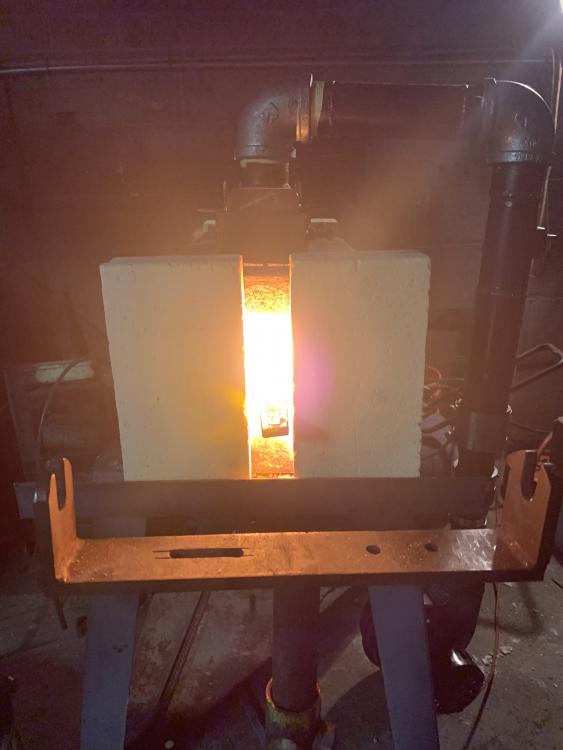

If that bad? That’s at 7.5 psi. I’ve said before like on my last post that yes I know my forge does not hold in heat worth a darn. I’m wondering if I should close those holes that the nipples are going into off completely.

-

-

OK I have a feeling that my Forge is losing way too much heat and that’s why I cannot get up to welding temperature because my forge will not hold in heat. Also I finally got my Venturi burners working and I think their tune pretty OK. Again I still wish I had somebody here that can help me in person but it is what it is. I am using .025 tips cut down about 1/16” so that the Meg tip is about halfway through the T. Whenever I run it on about 8 to 10 psi flames shoot up through the holes that the nipples are in but they’re not going up into the tease at least. They are trying to sputter every great once in a while though. I am still thinking about usingWhenever I run it on about 8 to 10 psi flames shoot up to the holes that the nipples are in but they’re not going up into the tease at least. They are trying to sputter every great once in a while though. I am still thinking about using trying the .030 tips just to see. Monday I will be going to the blacksmith Monday I will be going to the blacksmith and farrier shop to get Either more wall either more kao wool or some bricks or both. I’m thinking about squaring off the inside of the forge. Anyways, more to come and more to forge. Chris

-

OK I have a feeling that my Forge is losing way too much heat and that’s why I cannot get up to welding temperature because my forge will not hold in heat. Also I finally got my Venturi burners working and I think their tune pretty OK. Again I still wish I had somebody here that can help me in person but it is what it is. I am using .025 tips cut down about 1/16” so that the Meg tip is about halfway through the T. Whenever I run it on about 8 to 10 psi flames shoot up through the holes that the nipples are in but they’re not going up into the tease at least. They are trying to sputter every great once in a while though. I am still thinking about usingWhenever I run it on about 8 to 10 psi flames shoot up to the holes that the nipples are in but they’re not going up into the tease at least. They are trying to sputter every great once in a while though. I am still thinking about using trying the .030 tips just to see. Monday I will be going to the blacksmith Monday I will be going to the blacksmith and farrier shop to get Either more wall either more kao wool or some bricks or both. I’m thinking about squaring off the inside of the forge. Anyways, more to come and more to forge. Chris

-

I didn’t change the length of the length of the mix tubes to a different length than from the plans I actually cut them down to the length in the plans. 8” to 6”. I’ll send some pics. Basically one of the flare tubes that go into T and receive the mig tips is stripped out. So it not being tight is messing things up. That particular burner is burning way too rich. I switched back out to a.025 and it was worse that with .030. I’m thinking I should try a.035 trimmed down tomorrow after I get a new T and flare. I’m hoping the actual T is not stripped out but I think I threaded it too deep and it made the whole too big since the tap is tapered.

-

I Know , gimme a bit to figure this computer thing out and I;ll re-send everything.