metal99

-

Posts

362 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by metal99

-

-

I would love a big anvil, here in sask most of them are around 100lbs.

-

^ he is correct XD

-

Sparky, that anvil is in really nice shape. Don't worry about it at all.

Or... Actually it's terrible and you should let Rob take it ;) -

Looks darn good, I'd grab it if the price is fair.

-

Ahh yeah now I think I have dropped the hay buddon idea. The photos of the Samson you shared have changed my mind.

-

I want it! :)

-

Well, Google ain't perfect, but Google and Wikipedia can give you a headstart.......

The Guelph Civic museum gives you the name of a bunch of foundrys in the area, and a lot of cool documents if you search their collections. Found one wooden anvil casting pattern that looks a little similar to yours, but that beat up, hard to say for sure. There's also contact numbers if you wanted to call them to help you out.

http://guelph.ca/museum/?page_id=377

The big ones for the area (although) it looks like there was at least around 10 founders for the area were Callandar Foundry and Manufacturing Company Ltd., Wellington Foundry (or Wellington Mills), Mills and Melvin Iron Founders (at some point also Mills and Goodfellow Foundry) and Robertson Foundry.

Callandar looks like it was mostly cast iron wood working tools, saws, drill presses, that kind of thing until it was bought out by Rockwell pre-WWII, Wellington made farm implements, and Mr A. Robertson apparantly did all kinds of general castings, and during the American civil war was heavily involved in making cast iron munitions/weapons for the South! Google will find you all kinds of old advertisements, town histories, etc.....

NTK, you may not find everything on the internet, but it's still a fun journey, and the info and pics on the sidetrips and dead ends are fascinating......

Thanks for the info man! I appreciate it. -

That's most likely the problem or perhaps not properly normalizing and then quenching a little hotter then it should be. I lost a couple forging a from W1 that way.

-

Could it be an air hardening steel maybe?

-

GoldenBear, that is a very nice hey buddon anvil you've got!

-

Very relaxing video, thanks for sharing it. Your work is too notch!

Darn I wish I would have noticed my little typo before the edit option went away lol.

Basher, your work is really nice.got it for ya

-

Very relaxing video, thanks for sharing it. Your work is top notch!

-

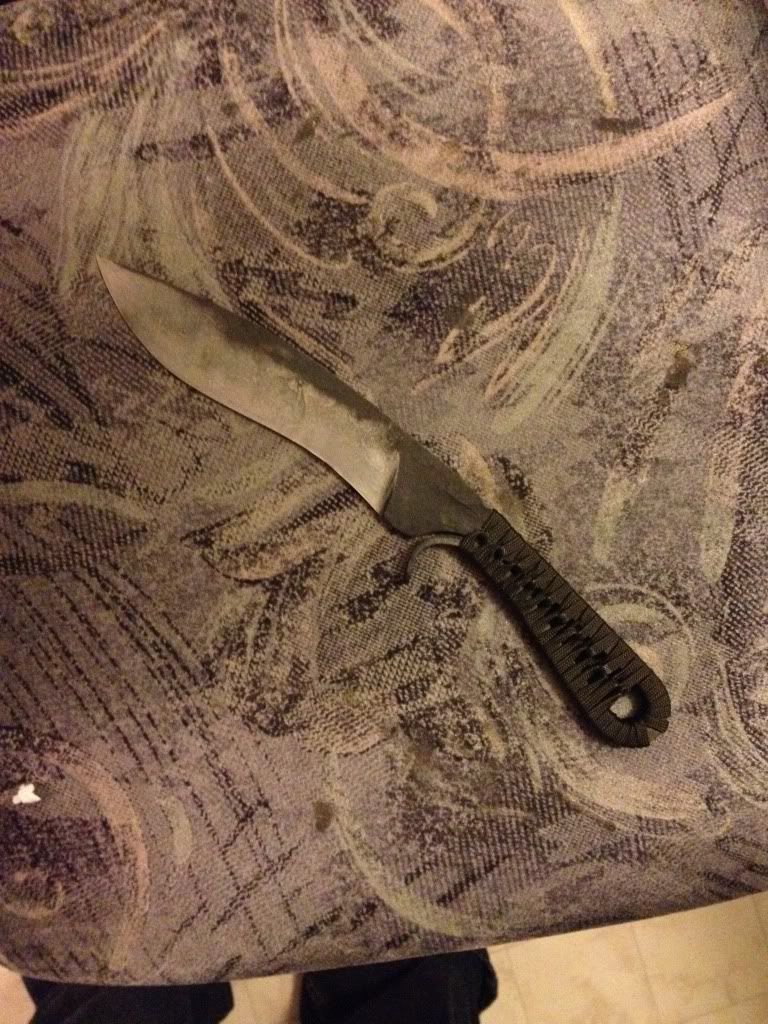

Not to sure what happened to the picture I had uploaded but I have the knife finished now.

I do all my forum posting on my phone and can't upload to the site directly so photobucket is my only option.

what happened is you posted off site and it got lost. sorry we can not help you

I chopped up a 2x6 and it shaved quite well after that. I might make the cutting edge a little finer but we will see.

-

Saw this anvil at a junk yard. Only an idiot do this to an anvil

I can't believe you haven't seen one like that being that you have so many anvils lol. I've only recently got hooked on anvils and have had the chance to buy quite a few with broken heels. I bought a 100 pound anvil with a broken heel for $7.50 and a 220 pound attwood's with the heel ready to fall off for $100. -

That's what my attwood's is starting to look like lol.

-

I have always been a big fan of your work, keep it up! :)

-

Thanks for the kind replies guys :) I'm not sure if I want to let this one go when it's done. I'm getting attached to it :)

-

Haven't done much work on the recurve lately but it's ready for heat treating now.

seems another reason to not post off site, when the off site place reforms their files, we lose the photos from the thread.

-

... I wonder if we will ever get to the bottom of this...

Since I got my second "WOO" anvil I have gone through EVERY page in the anvil section from 2008 to now and looked at every anvil I'd thread with no luck finding another one. That has taken me two weeks, I would read through the threads everyday and just finished yesterday evening.

We might have to talk to Mr Postman about these ones.

Here are my "WOO" anvils.

-

Any more info on your anvil Rob? I have two of these mystery "WOO __LKERS" anvils. Mine don't have anything on the side with the horn pointed to the right.

-

That's all that counts :)

-

I'm a little confused here. Not used to seeing quenchant used in the normalizing process. Isn't the idea in normalizing to cool the metal slowly? I understand its not the same as annealing but quenching, as I understand it is to cool as quickly as possible. Also, The term "heat treat" raises questions in my mind. I understand that "annealing", "normalizing", "hardening" and "tempering"all fall in the category of "heat treating", however, when I hear the pros speak of heat treating, they are usually referring to the final hardening and tempering. That being said, I would worry about the integrity of the metal that has been reheated to non-magnetic temperatures and quenched or left to air cool or otherwise, that many times.

Invoice for 2¢ in the mail ;)

Scott

No, when you normalize you let it cool in still air till a black heat then repeat. It's not usually a good idea to normalize more then 3 times. You can actually make your steel unhardenable by refining the grain to much.

What I meant by the wrong quenchant was for the actual hardening process. If you quench a steel like O1 in water.... Warps are sure to happen. -

Next time try an anneal, then 3 normalizing cycles or you can Risk refining the grain to the point that it won't harden. If it's warping after 3 normalizing cycles something is wrong with the procedure, most likely the temps being too high. The wrong quenchant can also cause warps.

Next time try that out and if that doesn't work I'm stumped! Lol -

you an octopus 99 ? :p

It's a possibility ;)

Manufacturer needs to give their head a shake!

in Zinc, galvanized, and coatings

Posted

Maybe it's not that people are stupid, it's that people all over the world are truly miss informed. It wasn't until I got into knife making and read the safety threads here that I realized the dangers of zinc coatings.

I have been a body man for 13 years and have welded a lot of galvanized body parts. Did they teach us the dangers if zinc in school? Nope!!! Practically every car made is galvanized and they are being welded every day by people that don't know the dangers of metal poisoning.