-

Posts

828 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Dogsoldat

-

-

Canadian sources make it more affordable unfortunately. The steel supplier I called doesn't have it, but recommended a supplier down in Vancouver or Richmond. something like that anyways. Think I'm going to make a hardy up and chop a short bit off to beat into it to make the right profile and go to town on it. Less than 4' should be quick to deal with.

-

That makes for a rather nice setup. food for thought for something out in the back lot

-

Renato Muskovic close by http://www.iforgeiron.com/topic/8171-renato-muskovic-anvils/

-

Kinda makes me miss the team I use to drive horse logging. Don't miss the fore cart that ran the swather, they had it figured out real fast that the thickest part of the field and 3 extra steps would stall it all out. made for a good ten minute break to clear it out and get it all going again

-

Depending on whats doing the hitting the plates will still flex and vibrate. Same principal as why it is not recommended to arc weld a face plate on an anvil only around the edges. At least that's my understanding of things.

-

Cool, that's good to know Charles I'll have to keep my eyes open. All the drums that have come through the shop have the shoulder on the outside that I have seen to date.

-

That piece with the square hole in it is the part of the tracks tensioner spring cage off the D-8 track frame. Have the square ended bolt that goes through it in the heap somewhere to. Figured it might make a nice stake anvil if I was bored one day. Had scooped the Rims from the scrap bin for a fire pit along with the axles and the drums are interesting because they are 14-16" diameter but maybe 4-5" deep. Had thought they might make nice fire pots for a forge.

One day soon I might have a power hammer. Need a bigger shop to squeeze it into.

-

I a going to need a striker soon. Getting all these good bits of hammer stock laying around itching to do something with. One of the trucks came in complaining that 3 out the 4 drives where turning when they where doing the push pull thing in the mud, D-8 cat on one end 545 Cat skidder on the other. So now I have a nice piece of T800 Kenworth axle minus the splines

-

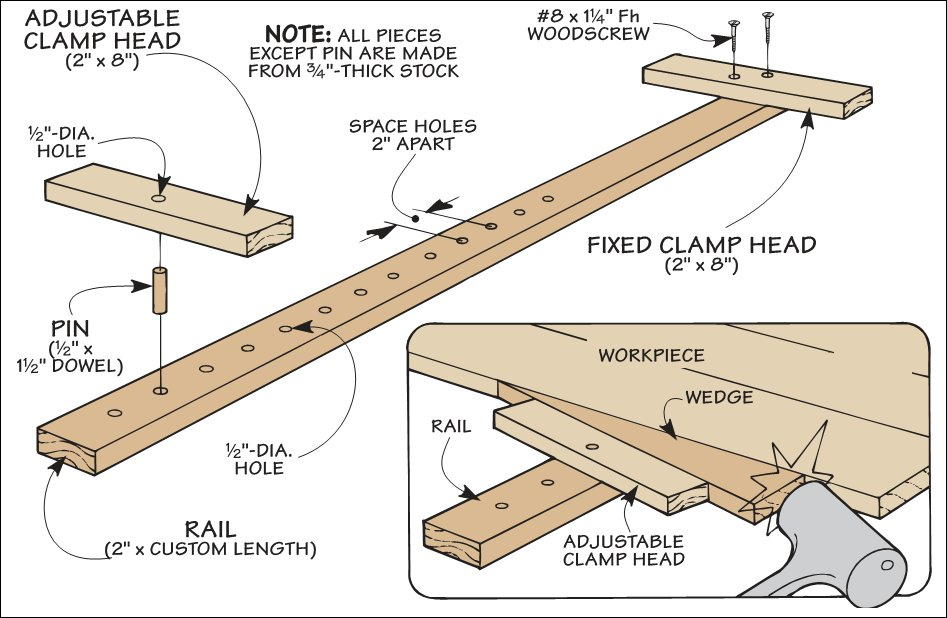

Do you have a holdfast for your anvil. Big heavy square shanked one to fit the hardy should generate a lot of clamping force,Can you make a strap loop and wedge that can be anchored to something. Simple in theory hard to describe. I've seen bow makers use something of the sort for holding staves while shaping. Just need a vertical mount instead of horizontal. Not sure what else to recommend, but I'll keep thinking on it.

or this may even give you an idea to work with

-

Had a short little end off a track pin from making my cut off hardy. Turned it into a cupping tool for a rounding hammer face. And finally finished up a set of hammer tongs that have been laying on the floor for who knows how long now. they are way to light for what I want but at least they are something. And a piece of the heavy spring, its 2 1/4" in diameter so if my math is right a 2 3/4" long piece should give me 3 lbs. Now I just need a helper to make a rounding hammer.

-

THANKS artfist! I now know what to call this stuff and can actually ask the right questions looking. If I have to I'll either forge it or grind it but at least I can now ask for it from the nearby steel supplier. Half the battle is done.

-

Man that turned out nice. Maybe I'll have to put a few things on hold and get at a hammer or two.

-

-

I have a handrail that needs to be changed and installed for the neighbours. It needs a short 44" section that comes out perpendicular to the wall built. It's easy enough by itself but I'm trying to find stock for the handrail part. It's 1/4" th x 1 1/4" wide with a radiused top. Maybe a 4" radius on it. My google fu is weak today and not finding what I'm looking for or what to call it properly to find it. Planning a small steel order soon and was thinking easy enough to add to it if I knew what I was asking for. I'll try to get a picture or two up to help explain better in a bit

-

Nice bit of work. May have to have a go at a few horseshoes myself. Is that a homemade rounding hammer in the first pic?

-

Thanks for that post Rashelle. Gave me a few things to think about that I wouldn't have thought of otherwise. Biggest is what part of the cheeks to work on while the drift is in.

-

With a decent fullering tool and the backing plate it goes surprisingly fast and easy. The hardest part on mine that I found was trying to square up the corner of the fork tine. Being spring stock hard to quench it enough that it doesn't deform when driving it down on the anvil to square the bend up without ending up so hard it's brittle. Further compounded by being small stock on a cool day losing heat quick.

-

In amongst other things today put proper handles on the tools. Made a backing plate for the vice and a dog wrench the way Mark Aspery does, but used a strip of leaf spring for it. The fuller tool has a little too small of a radius so I will have to make another at some point down the road. The handled hot cut was a real treat to trim the end off the spring stock before I started and cut to length at the end. was cool enough out to air harden the loop an the end of the handle. Needed one little tweak and it broke the curl off. So back in the heat it went to be drawn out again.

-

hehe ah they are not that big. the one at mom and dads is all of 16" bottom of his feet to the top of his head. mostly mice as far as I know. maybe the odd unlucky house cat.

-

Awesome job on the feet they just have that real raptor feel to them. The shape and hook of the claws makes me think of the stuffed great horned owl at mom and dads. Same deadly wickedness.

-

thanks guys was curious. had googled for it but nothing had come up and an inquiring mind wanted to know if it was my computer or something else.

-

Can anyone else get onto the Anvilfire page? Keeps giving me a this page cannot be displayed.

-

yep that would be correct

-

The hold down has proven itself already, used it to hold the top tools down while punching the holes. Been a real treat to have wish I had found the right sized stock sooner.

I've seen a video of an old gentleman carving the pliers may have even been posted on IFI. The springs are scary strong. quite the job cutting them down so I could extract them safely from the old track frame.

Hot and heavy work

in Blacksmithing, General Discussion

Posted

Managed a little time in the shop today. Straightened out the curve on the spring stock managed to get the hole punched. And the began to fuller to isolate the faces. Tried making a pair of tongs but just couldn't get into them, had a request for a couple more knives from a friend so flogged two off. Pretty happy with how the loops on the handles turned out.