-

Posts

283 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by LarryM

-

-

Richard, Happy Birthday!!!!!!

Bet can't wait for it the be over.:D

Bet can't wait for it the be over.:D -

Just go to a tractor supply or farm supply place and get a prince tie rod cylinder, remove the bolts, and cut it to length in a bandsaw, chamfer the cut edges, use shorter bolts and cut the ram to length. Off the shelf is going to be cheaper than custom built.

irnsrgn, Is right on the cylinder. I'd try to buy new what I'm looking for, there's less hassle. If you need it a certain length do like irnsrgn says shorten longer cylinder.

Question what are you using cylinder for? If you are building a hydraulic press. Do the math for an 8" diameter cylinder using 2500 psi power unit. It figures out to be almost 63 tons. That's big press. -

Sammy, This old WeldingWeb Forum thread has some old torch pictures. Check it out.

Welder Pictures

Enjoy!!

Larry -

Has anyone thought who is going get belongings? The reason I ask this question is I recently lost a good friend.

Who's hand written will is being contested. He willed everything property, farm equipment, tools, and etc to a friend, and former classmate. The family gets zero.

Who's hand written will is being contested. He willed everything property, farm equipment, tools, and etc to a friend, and former classmate. The family gets zero.

Be safe

Larry

UDATE:

Thought I let you know what took place here. The family is going to inherit most of the modern farming equipment, Tractors, Implements, some tools etc. The property is still undecided. So things did work out pretty well after all.

I personally did get:

Misc mechanic's hand tools and equipment.

Miller Bobcat 225 welder

Victor Journeyman cutting and welding torch with cart.

4" Blacksmith post vise.

Several tons of scrap steel:)

Here are some pictures of welder and torch setup.

So keep on hammin'!!!

Larry -

ataiter,

Below is another site to visit. The thing about this design is there is no slider bar to build. The connecting rods could also be replaced with more suitable pivots. These plans could also be scale up to make a larger verion. See want you think

Larry -

Otto, Pictures are in the IFI gallery. To answer your question this baby is going to be a handy addition the my shop. I successfully bend 1/4" plate in the press brake part. I also smashed 1-1/2" and 2" x 3/16 wall pipe. I haven't done any hot work yet. If you use a porta power weld a pipe socket to the base, and lower anvil. This will hold the hydraulic ram in the press. Trampoline springs make good return springs if you decide to just just use a hydraulic manual jack. I've been thinking about building another with 2" pipe uprights just to see how it works. Below is a preview of pictures.

#1 Press No Dies

#2 Fuller Dies

#3 Press Brake

#4 Channel Iron Bottom Dies

and light 14 ga. sheet on the right that I bent

Hope this helps,

BE Safe

Larry -

RC, Check this web page it get you started. I built one similar it has'nt been used much so don't know how long they last. I plumbed mine with square tubing to make the fittings, and fan hook up easier.

Fabricated Fire Pot by Bob Patrick

Larry -

Ironworker

in Shears

Warren, Is it hydraulic? If so all you need to do is make a stop to stop the stamp from entering the steel more than you want. This of course would mounted on the lower anvil part of the press. Did you get any tooling with ironworker? Please post pictures. We love pictures. Merry Christmas.

Larry -

Stixman55, Go to UserCp top of page (Green Bar). Then click (Edit Avatar)at the left of the screen follow instructions there. You'll notice the first box should be unchecked. At lower part of the page you upload your picture. (browse,select,upload) Then click save. Now you have your avatar. Done:)

BTW you can change your Avatar anytime.

Hope this helps

Larry -

kovacija, Looks great!!

I see you truly been bitten by the blacksmith bug.

I see you truly been bitten by the blacksmith bug.

keep them picture and videos coming.

Keep on hammerin'

Larry -

You can melt aluminum with charcoal briquets if you have to. With crucible made from pipe capped on one end. You can make a wheel very easily melt the aluminum. Then skim the dross off top of the melt. You then just pour it in empty coffee can. Pour it a little deeper than you what finish wheel. Once you have a blank wheel center and drill it. Then do all your machining on a mandrel.

Hope this helps

Larry -

Ainslee, This is my pray for you. "May you be well and home in time for Christmas. Amen

Get well soon:)

Larry -

Frosty,

I'm sorry to hear about you lost. I know it is hard to lose a parent. Personally I start thinking about my own mortality. Just so you know we'll be thinking about you and sister on this end.

Larry -

This my version of mini hydraulic press that was introduced to the forum by Ken Kelly. Thanks for sharing Ken. I didn't follow Ken's example exactly. I used what material I had around 2" angle for the uprights, and 8" channel for the base. It's not finished yet but thought I'd get everyone's opinions. More picture to come, as I make progress.

Can't insert pictures so click to view

Larry -

Jayco,

One thing you can do to make your stove more air tight is to roll up lengths of tin foil into a rope like shape. Then use it as a door gasket. It works on my homemade wood stove. With door gasket it will burn all night.

Larry -

Pascalou, We call that hoar frost here. Nice pictures

Larry -

Here's a link to one I think you'll like:

A simple homemade propane burner

Larry -

Nice views Larry.

Any fossils in them thar hills?

Frosty

To answer your question Frosty, Yes, The top of the flat top mountain is full of marine life fossils. They have also found many dinosaur bones in the area. I have been experimenting with my digital camera. This the first time posting pictures. I'm glad to hear you like the views. I a have large album on photobucket so if like I can post a hot link to it.

Frosty, I used to live in Anchorage, and Wasilla. I worked as machinist, welder, school bus driver in Anchorage. So i know where you live.

Larry -

-

Russell,

Just so you know gold color screw means black (line) wire should be connected to it. Which is what you see with the switch. The white wire is a neutral which completes to circuit. If you look on wall plug you see silver colored screws on one side and gold colored on the other. Which means the white (neutral) wire goes there. The same thing applies to electrical extension cords if you change the cord end look for gold and silver screws, and wire accordingly. Thats why these days we have a wider blade on male plug. So neutral wire is to neutral, and line wire is to line. The green wire is a ground wire which just connects all the electrical equipment together. That way you don't become the ground, and shocked. -

BEWARE of Cadmium it is much more dangerous than metal galvanized with zinc. When heated Cadmium gives off extremely toxic fumes. 29CFR1910.146 OSHA Confined Space Regulations have a special cavaet about welding with cadmium containing rods in confined spaces that states:

"Note: Some materials -

Just so you know there is a lot of aluminum work to be had around boats and marinas I have done alot of boat repair work in the past. I like aluminum because won't rust, and you don't have to paint it.

Larry -

Most of the barbed wire I have purchased lately is not galvanized. It has a cadmium coating much like the bolts you buy these days. So I think if look around you may be able to buy the same wire.

Larry -

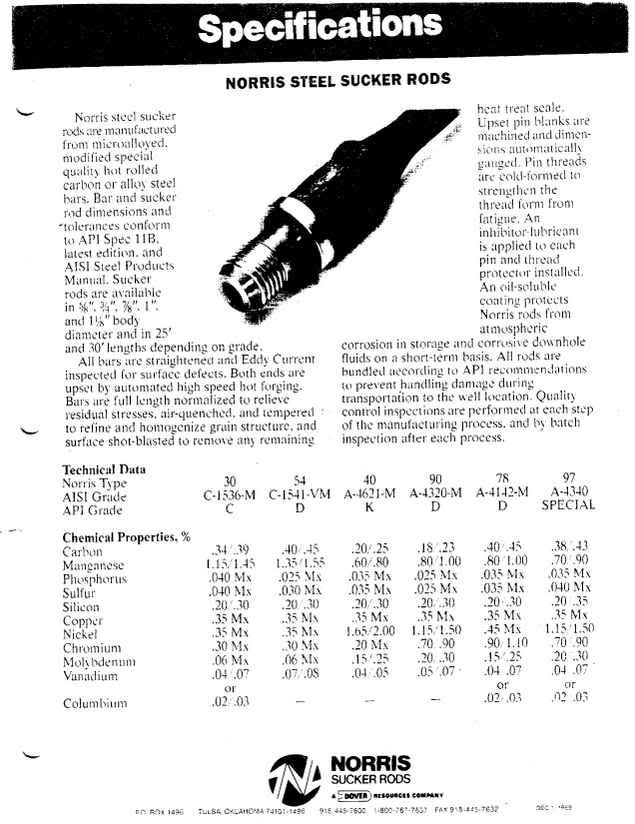

What is sucker rod?

Paul,

This link gives specs for one brand of sucker rod. In the picture shown you are looking at the male end of the rod. This link was shared by IFI member Irnsrgn, one night in the chat room, that I bookmarked. So Thanks Irnsrgn.

To answer your question, It is used link the above ground mechanical pump rig to the underground pump unit. This pumps are used to pump oil and etc. from bottom of a well.

Nos, Look on the flats of the square part of the ends, to see what kind of steel your rod is.

Let your imagination be your guide as to what make with your material.

Larry

It's real quiet out there when you are by yourself.

It's real quiet out there when you are by yourself.

CSteel vs Iron?

in Blacksmithing, General Discussion

Posted

nashdude, The best way to identify unknown steel is the use the grinder spark test. I won't go into detail but just spark test steels that you do know the carbon, alloy content of, and compare with unknown steels. There is also pictures available to compare with. This is not an very accurate way to do it but It will give you and idea. You can also just experiment with heat treating different steels. There is a lot of info either on the internet, books to get you started. If you know what the steel was used for in it's previous life that will get you a place to start. Like most of the people will tell you if you are making something special (For Example Knives) use new know steels.

Larry