-

Posts

758 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Farmall

-

-

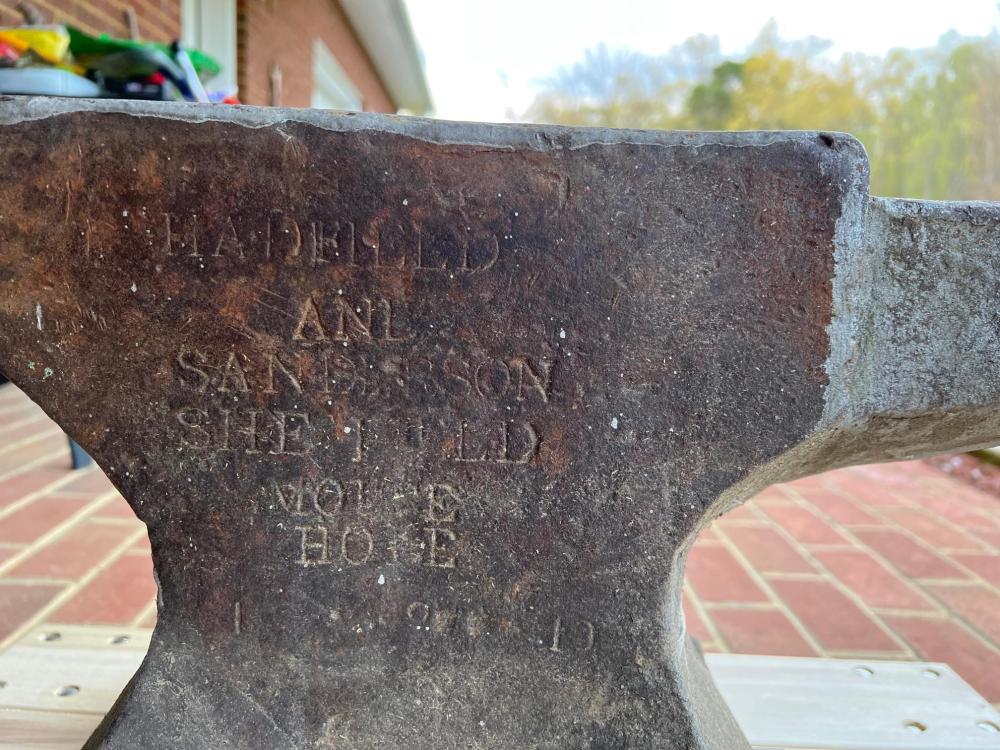

Just got this anvil away from my cousins. This anvil was used by my dad, grandfather, great grandfather, and great great grandfather. It was partially painted silver and am in the process of cleaning it off and make a few things on the old girl. It is marked Hadfield & Sanderson Sheffield Mouse Hole, with weight marks of 1 2 10 or 178 pounds. I was hoping to be able to get an approximate date of manufacture or just whatever information I can find. I am pretty excited about getting it - took about 3 years of talking along with making a few things (bottle openers, christmas decorations, crosses, etc) to show them it was going to be put to use.

Anyway, thanks in advance for any help. Here's a few pictures.

-

There were many different manufacturers of these. I've got a Rockwell, Belsaw, and my brother has an Emerson. They are pretty handy. There was a guy selling replacement wheels and platens for these on Ebay about 5-7 years ago.

At the Vintage Machinery DOT Org website, they have a manual for the Rockwell available for download.

-

Thomas it was probably Cass West Virginia - they have Shay locomotives that I have ridden on.

Frosty, as to steam trains, my great-grandfather and grandfather helped the Norfolk and Western Railway build steam locomotives. When I was little, Granddad would take me to the Transportation Museum and show me the locomotives there that he helped build. Would talk about the challenges they faced with each one. Such amazing machines. I love to watch them and think of my ancestors when I see them go by on excursions.

-

In the Colonial Williamsburg photo above, that rear forge with the fellow in the white vest has the bellows mounted upstairs so its out of the way. The forge that Mark Sperry (the smith in the dark vest) is using has the bellows mounted below the ceiling with the same pull handle. It is mounted below the ceiling so the visitors can see the bellows operate. These are side draft forges and the air enters at the rear and bottom of the forge. I've got the drawings for the forges somewhere. I got them from the Colonial Williamsburg Foundation when they rebuilt the shop.

-

-

Thanks. I can do the cleanup if you don’t want to.

-

true. i dont mind that option, but its a lot of trouble for Thomas to pack and ship rather than take and give to someone. I do know some that will be going

-

I cannot. It will be my fathers 91st birthday and that will always beat out quad state. May have some friends going though.

-

man i wish i lived closer Thomas.. I'd take that off your hands been looking for a 4-inch bullet to hold the heavier things i need to work on Good catch!

-

I've used one of the larger round holes to hold my stump anvil before

-

one thing you can do to texture all the edges is to heat the blank before you start, then use your hammer to texture the four sides. Then heat again and form the cross and texture what was the inside.....now all sides are textured.

-

Well the article says :

"Mining irons were discovered in both areas; mining wedges and the remains of an iron lamp were discovered at the second mining area."

and the 3rd comment added to the article has this explanation:

The mining iron is a wedge- or chisel-like tool about 15 cm long and 2 cm wide. The tip is called “örtchen”, and the striking surface is called a “bahn”. The iron has an eye in the middle, into which the handle (“helmet”) is inserted. The helmet is not wedged tightly in the eye, but only inserted relatively loosely and protrudes. This makes it easy to separate it from the handle and not only penetrate deeper into a cleft, but also to slip on a new iron. This was necessary several times during a work shift, because the point iron quickly became blunt. Therefore, the miner always took several irons to work with him, which were re-sharpened in the miners’ forge after the shift. For transportation he used the iron belt, which in the past was actually a leather belt, but in later times, around the beginning of the 17th century, was formed as two flat irons with a carrying yoke. The name iron belt remained…

-

Best part of living on the dairy farm is getting up in the morning and smelling the dairy air!

-

Dad and I made 4 foot by 10 foot raised beds by first marking out the locations (there are 6) and digging down 2 feet into the native soil. We then used 2 2X!0's to make the beds 20" high. Took the native soil, mixed it with the same amount of composted horse and turkey manure and filled the beds up to the top. Lotta starting work, but they sure produce.

-

best of luck on the new venture.

There's a woman in my guild that is a fiber artist, making her own yarns and dyes them and knits, crochets, etc. She makes copper yarn bowls that she says sell really well.

-

Here's my anvil envy - Yesteryear Forge's 1241 pound Reflinghaus......It's a monster. I've watched them work on it and the work seems to go so quickly.

-

We can always ferrous out some good puns

-

Kneemail sent

-

Daswulf, only flared on one side. I will wander through 1887 patents to see if I can thread the needle in the haystack. I just thought they were an interesting tool and, as a result, had to have them.

-

Seems reasonable Daswulf. Now to find the flaring tool!

-

Not sure what followed me home....was hoping for some identification help. I think (using that term in the loosest possible manner) it might be for riveting. The only marks are 1887 (stamped) and a diamond shape with the letter "B" cast on one side of the wing nut and 7/16 on the other side. Any and all help/guesses/conjectures are welcome.

-

Sounds like a 16 pound shotput for track and field.

-

I believe it is a john Brooks leg vise. I believe on line used to sell them back in the 70's and 80's. I have one (it's marked "JHB") and there is one in the silversmith shop at Colonial Williamsburg.....with the leg at the right height for my use and obviously they found a leg length that works for them. They were sold with a jam nut to put on the leg and tighten it to make it more solid. They show one and discuss it on line as Brooks leg vise.

-

Actually, the first Thanksgiving in America was held at Berkley Plantation in Virginia in 1619. A day of Thanksgiving was declared that day. You can google for more information. Pilgrims were 2 years late.

happy Thanksgiving to all

Hadfield and Sanderson Anvil

in Anvils, Swage Blocks, and Mandrels

Posted

No worries on grinding.....just a wire brush wheel and some WD40 to help me clean it up. I appreciate both responses. Frosty, my uncle took it out of the shop at Granddad's to his house years ago.......and never used it. He passed away and I've been after my cousins to let me have it to put it to use.....none of them have any interest in blacksmithing so I really don't know why they wanted to hold on to it. Nevertheless, I did get and, while it will not replace my Soderfors Frosty, it will be used to make some things for the family.