-

Posts

29 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

Jacksonville, Florida

Recent Profile Visitors

1,995 profile views

-

I have a dual burner Fucina. It works well enough. I can forge weld. I can make small pieces of 1095 / 15N20 pattern welded steel billets. (Could make them larger if I had a power hammer). Over all. Nice forge. I block both sides with fire brick to help heat up the larger stuff. It is a nice forge and value for the money I spent. Once heated...the stainless doesn't look anything like stainless... It doesn't stay shiny. I think I would prefer forge with thicker steel walls.

-

I'll buy it and be the guinea pig. It's a small investment to find out if this "Off The Shelf" product is worth it. Dual burner on order. The bad part. Don't expect any customer service. The forge ships out of Cyprus, yea, Cyprus the country in the Med. Downfall, shipping is one month. Not very good for the impulse buyer!!

-

Yes I did. I is a nice machine. I haven't been back on here since I got cooled down for some time by the moderator. I promised an "Un-Biased" review, but have been skeptical about posting. I have made many knives since the acquisition of the machine and am satisfied with it. Regards... Mark

-

Very thoughtful, thank you for your comments. My intentions were not to come off abrasive. It did seem as though I stirred the pot. As a craftsman myself, I understand and respect those who have more knowledge and experience than I. It just seemed like a bashing. I will be more thoughtful and try not to read to deep into comments. I will research the brands you mentioned before I make a decision. Thanks. Well aren't you a sweetheart.

-

I would be delighted if you could direct me to a half price machine with the same capabilities. Maybe I could avoid a purchasing mistake. I will be much appreciated.

-

Actually Professor, my question was a "Yes or No" question. I don't recall asking for advice, rather than looking for product information. But instead of anybody that actually had knowledge of the machine, the posting just got blasted with negative comments.

-

Welcome to the international "Hate Train". Thanks for all of the negative comments!! Can there be anything positive here about this completely sub-standard machine which just happens to be affordably priced. Well, tell ya what. I'm going to be the self appointed "Guinea Pig" and buy the machine. I will give a very detailed unbiased report on it once I have it. The "Funny Named" company I will admit was somewhat of a Kill Joy!! ***beautysupplyworld***, What the heck...

-

I am looking at this belt grinder on ebay and am wondering if anybody here has bought one or knows about them? link removed PH 427 X 12" Wheel & Flat Platen Tool Rest 2 Hp 110 Volt Belt Grinder 2" X 82" Grinder Variable Speed Package Content 1 × 1.5kw Electric Machinery With All Copper Wire 1 × 2.2kw Vector Transducer From RILIPU 1 × Toothed Rubber Wheel And Independent Movable Rod 1 × Flat Grinding Rack With Independent Movable Rod 1 × Concare Grinding Rack With Independent Movable Rod 2 × Concare Grinding Wheel

-

Yet another power hammer build question

mfkerr replied to Michael Cochran's topic in Power Hammers, Treadle Hammers, Olivers

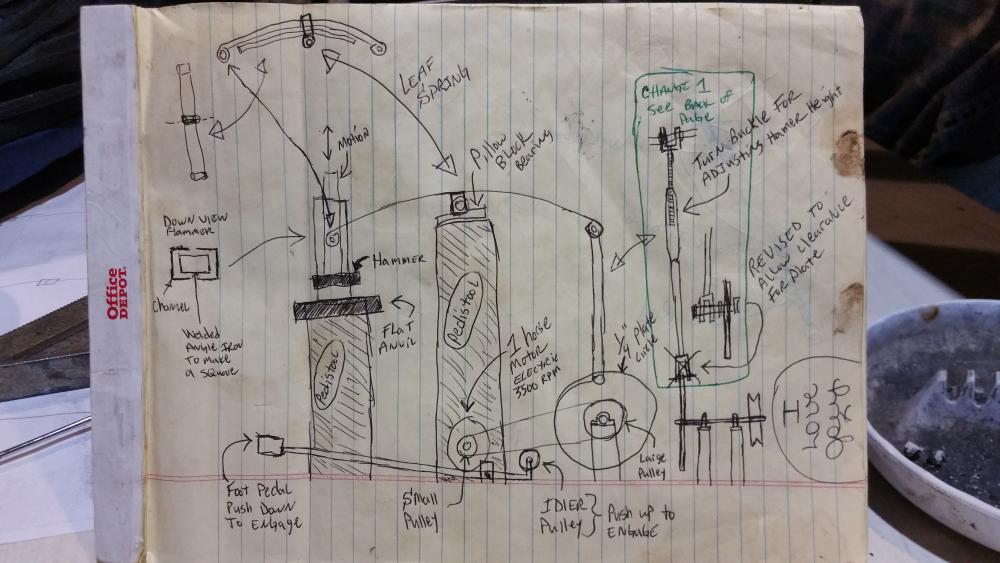

Here is my original design. Probably drew months before building. I used it as a guide mainly to keep me focused on the end goal. As you can see it in reality, it is conceptually similar. -

An honest and modest fellow. I commend you. That is such a great quote. I love it!!!

-

Yet another power hammer build question

mfkerr replied to Michael Cochran's topic in Power Hammers, Treadle Hammers, Olivers

Do you have a basic design you could post. I made a hammer and I have a lot of lessons learned I could pass on to you if your design is anyway similar to mine. Here is the link to some pics, hammer pics are about half way down in this long post. Feel free to give me some pointers as well. http://www.iforgeiron.com/topic/47990-kerrs-forge/ -

You are very kind with your words. I have been a "metal" craftsman for my entire adult life. I seam to have a passion for "Bladesmithing". I've never had instructions or training. Back before U-tube it was all trial and error and a few tips from my pops. Now with the internet I can read and watch instructional videos and get good feed back in forums like this one. I have made "File" blades as far back as 14 years old, but my real interest has developed into forging over the past several years. I do have the confidence to think I could atleast get through the first cut on "Forged in Fire", Ha, Ha,...maybe.

-

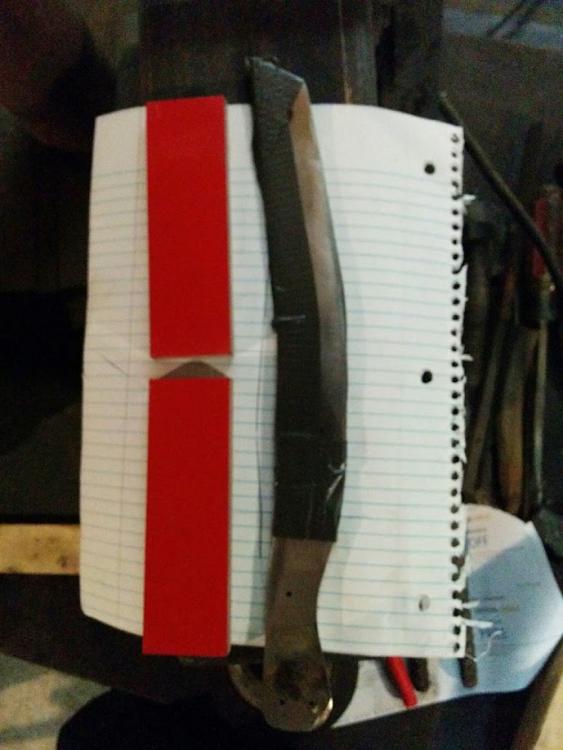

OK, think the pics will show up now. I have some progress on the square axle stock. The knife pictured next to the scales I plan to attached. Anyway, about the polishing. The first part of polishing is the "Grinding" or shaping of the rough hand beaten, sloppy hammer work, to remove dents and form the shape you couldn't get straight out of the forge. This is with a hand mini side grinder with grinding wheel. 2. Next is mini side grinder with 60 or 80 grit discs. 3. then 100 or 150 disc on the side grinder 4. some times I will use my belt sander with various belts, but my belt sander is a real piece of SHAT. (China, small, no power) 5. I have quick replace sanding disc which I use in my drill, grits from 80 to 2000 (They work great) 6. Polishing wheel on bench grinder, first white compound then red. Sometimes the polishing takes longer to do than shaping the blade from "Raw" materials. To achieve the mirror finish on the small but of the spike probably took 1/2 hour. To get the same finish on a blade, ugh..., 3 or 4 hours maybe longer depending on hardness of blade. Talking about a "Flawless" mirror finish. Here is a custom handle I made. (Not the blade, it is an Ebay bought blank, I'm not that good yet...) It was a crazy idea. I think it is a beautiful show piece, but I know it is not durable. The "Jake 2016" my custom hand made laminated wood and sheath. Again, I didn't forge the blade. Ebay did it for me. But the handle is solid on this one. The last one is just a little ol ugly RR spike and a rough @ss sheath I tried to "age" but that didn't work out to well. (Oak plywood handle)

-

I have been polishing much longer than forging. But I would say the spike took about 1.5 hrs or so. This pic below is a modified version of a Kukri made from U-bolts from an 18 wheeler's axle. The tempering is excellent, though I didn't try to cut a nail with it. But I forgot to drill my holes befor the tempering and I melted the drill bit on the fourth hole. This was just a practice session so I didn't take a lot of time with the scales (Handles). They are from 3/4 oak plywood. a.jpg Next Project. Old square axle. I will put nice handles on this one. b.jpg

-

Thanks Bigb for the clarification.