mb44kar

Members-

Posts

9 -

Joined

-

Last visited

Profile Information

-

Location

Columbus, Ohio

Recent Profile Visitors

375 profile views

-

Not sure if this is known already, but figured I'd let others know if not. I sent an email to Mr Volcano's customer service, asking about when the Hero forges would be back in supply on Amazon, I was looking to get one as I was getting tired of the firebrick and MAPP-torch forge. I just got a reply from them. The gist of what they said is that they will no longer be manufacturing forges, but will continue to supply forge materials and tools, like the satanite, kastolite, rigidizer, and steels/heat-treat oils. They said the heightened market competition made it too challenging for them to sustain their operations in a fiscally responsible manner. Very sad to hear personally, I was looking forward to getting one. But I'm happy to use their rigidizer and satanite on one of those super cheap forges with a silly Amazon name.

-

Sorry for the pics being so unclear, it's tough to get the right angle and also not have the powder get into every tiny crevice. I think I can see "IGH" center, and just below the A. This looks like it's a Peter Wright from this, also the font of the numbers seems to match for whatever that's worth. What convinced me was the thumbnail from this fellow's video (not affiliated in any way): But I'm just guessing still. No matter what it is, I'm going to put a hammer to it. I bought a used jackhammer chisel and I'm going to try to make a hardy tool from that.

-

A bit I think...Let me know if you can make anything out, I threw some baking powder on it. I spent the Sunday this weekend picking up some free oak and black walnut logs from a golf course. Got the anvil mounted to the big oak log today, and I'll use the black walnut for handles and the like. I also very lightly dressed the edges with a flap disk and coated the body in hydraulic oil because the transition to Spring brings out the sweats in metal here in Ohio.

-

I don't mean to interrupt a good breakdown of FIF... but clean-up has revealed a few things on this anvil! It has a flat bottom (does this indicated a manufacturer? I have seen lots with sunken/relieved bottoms) and there is what might be a circular logo with an A in it. See attached pics

-

Gotta respect that, lathe is the most fun machine tool for me. Glad to hear it was money well spent on my part. Makes sense, thanks. Too right, I don't hold any bad feelings about the experience. Still just surprised how small these suckers are for their weight. I'm used to moving 1-2 ton machine tools so this was a walk in the park. With all the FIF bashing, I wish I had actually watched it, might have gotten into this earlier! And with way weirder expectations...I heard of it but just never got the chance to get into the series. I got interested after making a knife for my dad (and starting one I'm currently working on for my mother) the abrasive way and seeing lots of forged examples. Also, learning about how the Garand receiver was forged 8620. It seems like a good way to supplement my machining capabilities, forging parts to a point where they can be finish-machined, maximizing strength from grain alignment but also getting precise results.

-

Understood, I'll get a 3/8" ball bearing for any testing. Based on what you've said my plan is to wire brush it off all over and then lightly blend in the chipped edges with a flapdisk. It will take me some time to shed the machinist's precision when considering the anvil face, I have a dial indicator that reads 0.00005" so I can worry over surface finishes on the lathe. Non-knotted wirebrush, noted. Just seeing the "mouseholes" around the base makes me think it's forged, and the "step" in the feet of the base make me think Peter Wright (from my weekend of Googling..). But I think I saw a picture of a Trenton with that same step at some point...I'll probably go for the wax and also try the powder trick, thanks. Thanks for the corrections, guys. The seller said they had it on a scale that read 250 lbs, either their scale is off or that seller is a piece of work. Either way, I paid closer to $4/lb. Oh well! Still seems like a great starter so I won't mind the price. This at least explains why I could deadlift the anvil without having been to the gym for a long while. COSM is pretty close by, I'll give it a look! Thanks for pointing these out.

-

Hey Frosty thanks for the words of wisdom. I didn't even plan on wire brushing the face, at least not with my powerful 9" angle grinder. Maybe I'd trust a drill wire brush attachment with that task, something that wouldn't have near enough power to do any harm. I've also got a 1" ball bearing on the way but I won't drop that from any serious height on it. Unfortunately I have to wait for a coming move before I get this situated on a stump or wood block and get to really using it. But it does free up that stainless stock for mill work if I want. I did the tap test as I said, up and down the face and on the horn and tail. To my untrained ear, there were no dead spots but you're right I could be missing subtleties. I'll do a pseudo drop test with that 1" ball bearing while it's still in my trunk (it'll probably sit at a self storage, with a coat of oil, between now and my move) and see. True, thanks. I added my location but it for some reason has no space between the town name and "Location". Isn't there another strategy for getting sharper edges where you make (forge? mill?) a block with a knob that fits in one of the face holes? Hardy hole, that's the term. And a last question, the numbers near the waist, to me it looks like "L 3 70" or "L 3 72" Are those meant to be the weight or year of manufacture? Thanks again guys.

-

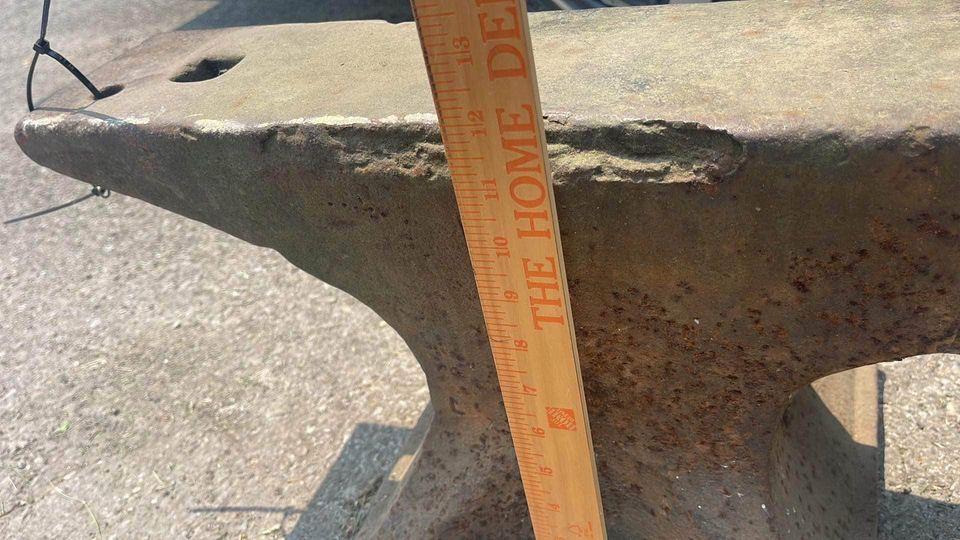

Here are some more shots after I got it into my trunk. ...Disregard the mess of a target stand in there. This is in central Ohio, for reference.

-

mb44kar started following Anvil ID and How'd I do?

-

Hello, glad to be on this knowledgeable forum. I'm more of a novice machinist with some minor heat treating experience (in plain carbon steels). I've made a 1095 stock-removal knife and plan on another soon using some 1.3% plain carbon steel, but I also found some 6150 steel for cheap and have been attempting to forge it for a few days now. I have been using my heat treat oven as a forge, and a 75 lbs block of stainless steel stock as an anvil. I was getting tired of the bounce from that, and how much it would move side to side. Having planned to pick up forging at some point, I decided I may as well see if any anvils are in my area. I was out looking today and found a ~250 lb anvil for $3/pound, which I've heard is good. I picked it up after I tested the sound with a hammer and it rang decently. I can't find any maker's marks on it, can you tell who might have made it? I also picked it up thinking I might be able to weld the face where edge bits are missing, or maybe mill it down. I should have realized then, but welding is a no-go because it would temper the surrounding area. Are these missing edges a deal-breaker and was I a dang fool? It's going to be better than my block of stainless steel for sure, but I got too excited at the price.