-

Posts

10 -

Joined

-

Last visited

-

I love Bob Ross. Ideally, I would like to get to a place where I am using older methods in the creation and forging of billets... and newer technologies in the forming and finishing of the blades. I did manage to find an old small kiln this weekend in the boonies of the shop, it measures 8x8x24 inches. I will have to refit the gas line though. We are cutting some 3/16" 1095 this week for a pulp mill on the island, so will see what I can get from the off-cuts.

-

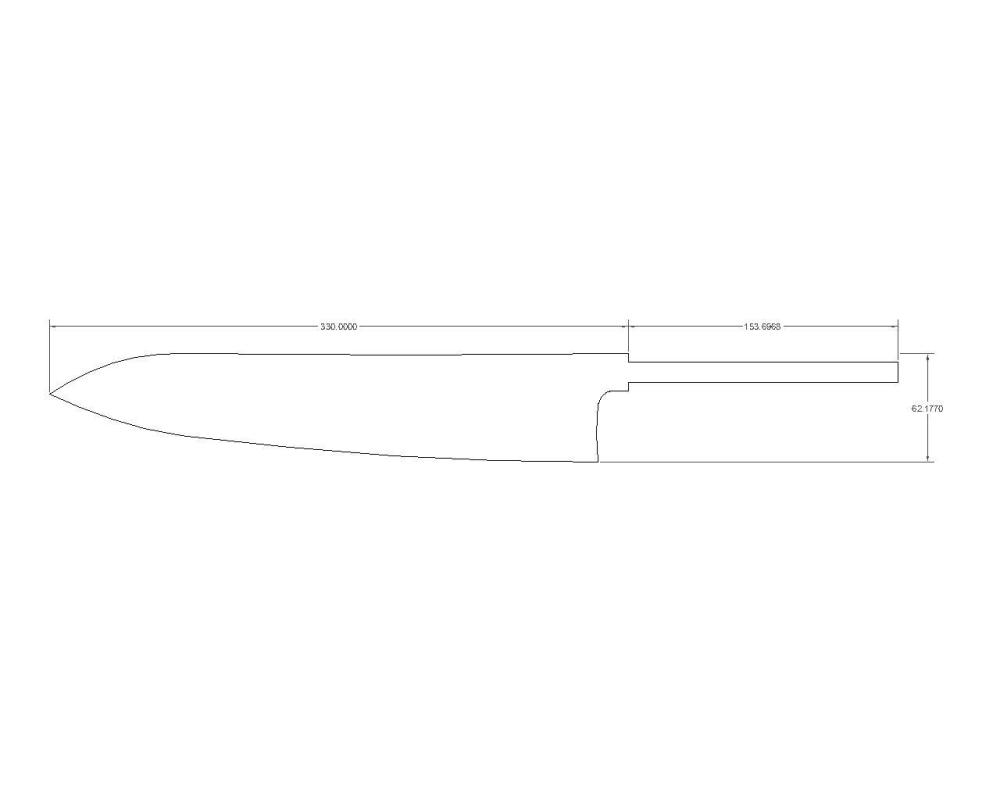

I was wondering about that last night, I found some good articles. I feel like the process of material removal lends itself easily to having a linear taper, but I think for my next project I may cut 2-3 blanks and try a convex taper as well. Will take some time and patience. Going to cut the attached project tomorrow after my kids lacrosse game. Also wanted to say that I noticed that in some forums, working with waterjet cut blanks, etc. is highly frowned upon, so I really appreciate everyones input and welcome to the community. If the process I have access to isn't appropriate for this forum group, please let me know. Would hate to be wasting peoples time.

-

absolutely... it is one of the greatest benefits to my work. I have only 1 rule for the machinists and labour... if they sell the offcuts/ scrap, the money goes back into purchases for the staff (coffee makers, beer for fridays, pizza, etc.) and if they are using it for their personal projects, the foreman or myself have to approve the material use ahead of time.

-

good tip... done. I like this style as well, I made this pattern in October out of UHMW for my 12 year olds costume.

-

amazing app for reference. Thanks all.

-

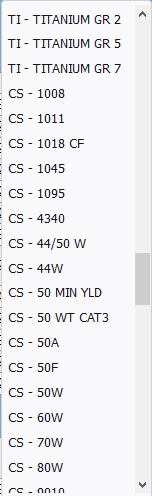

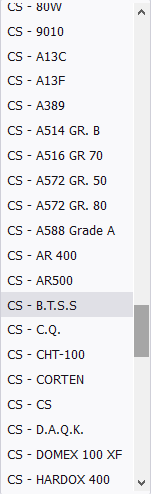

Swedefiddle - If I can get things sorted out, then I will for sure reach out. Iron Dragon - thank you for the welcome. Thomas - I agree about the titanium. Some of the work we have done turns out truly beautiful and the guys love cutting it because of the light show. End of the day today, we will be digging around the shop to try and find that old forge. I cut some 440c last night as a test, I will play around this weekend with the etching and edges to see what I can figure out. I'm tempted to throw it in the 5-axis mill, but that's kind of cheating. for the few people who sent pm's, here is the shop... currently running 2 water jets, 10 kw laser, some fab machinery, and lots of stock. we specialize in high nickel, titanium, stainless and duplex alloys. We cut a lot of squares, cirlces and rings.

-

Hi George, thank you for the welcome. I updated my profile and location. I'm over on the west coast of Canada, where we love our pubs just as much as any other region of the world! Definitely going to start with the 1095. Will cut some blanks tomorrow and come in on the weekend to have a go. My shop foreman says we have an old kiln, so fingers crossed. Agree with you on the joy and benefits of working metal with your hands. My dream is to build my skills and knowledge and become some-what accomplished. Practice and patience makes perfect.

-

Thanks Thomas, all good points. I have some 1095 offcuts I can try. I will be cutting the profile and then removing material with a belt grinder. I will definitely try doing heat treat with a torch. Will save the 440c for a future project. I hear what you are saying about this not being a start up... but you have to start somewhere. This is purely for pleasure and entertainment during my down time. We only have 1/2 and 1 inch titanium right now, so will have to wait until we get some gauge offcuts.

-

I will be sending it over to another shop. I am cutting some of their material for them, and they will heat treat 3 blades for me. Would love to do it myself, but that is another side project I need to make time for.

-

Super Fab changed their profile photo

-

Hi all, brand new member, but I love alloys and fabrication. I am having a great time reading through the forum and am happy to have found it. I am recently more and more interested in knife making. I have access to all sorts of machinery and materials (I have attached some below)... and I desperately need a hobby since my spouse has deemed the pubs out of reach until covid is sorted. I would be drafting the templates and cutting the blanks with waterjet. I am wondering if anyone can point me towards a good starting alloy? My gut is leaning towards 440c, but ultimately I would like some advice. I hate wasting material. Thank you.