Gandalfgreen

-

Posts

379 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Gandalfgreen

-

-

-

the end that fell off is originally the bottom that sat on the wood form. and I agree I think it's too smooth so need to wrap next time and overlap it Into the forge and onto the steel more. cant do anything until get more KOL lol said that b4. yes wool rigidized.

-

-

about to have my first fail lol out of propane but I did know I was low just wanted to get her dried. need go to store and get some things done then think i will come back heat my first piece of metal.

will say this very happy with my work zero cracks formed woohoo

-

-

thinking about heating up with a propane torch have one for like asphalt work or weed burning

-

-

Pat I will tell you what mine ends up like later today. like the brackets for the bricks saw something like that online thinking about doing same thing when welding gets better.

-

Thanks Pat cant wait to use it. Made me happy when form pulled right away was so nervous but win for vinyl and plastic cutting boards.

-

totally understand what your saying I love learning from a good chef. last lesson I learned was how to skin a salmon no knife blew my mind how clean it was too. had never seen done and I have cleaned alot of salmon

-

one day I hope to definitely take a lesson or class on bladesmithing. just doesn't fit into my schedule right now especially with me just getting offered new job as long as everything go thru I will be back to full restaurant hours. bye bye weekends and holidays but need the money to get things right and tight money wise and enjoy my forge Monday and Tuesdays with a lot of self teaching by hammering and either doing it right or doing it wrong and learning not to do that.

-

THANKS JHCC and FROSTY

That knife is what I hope to make one day. so beautiful excellent work. if 1 day I make anything a tenth that amazing I would be ecstatic.

-

oo I make lots of mistakes that's why I am so smart hahaha....... wont know unless you try every mistake is a lesson learned.

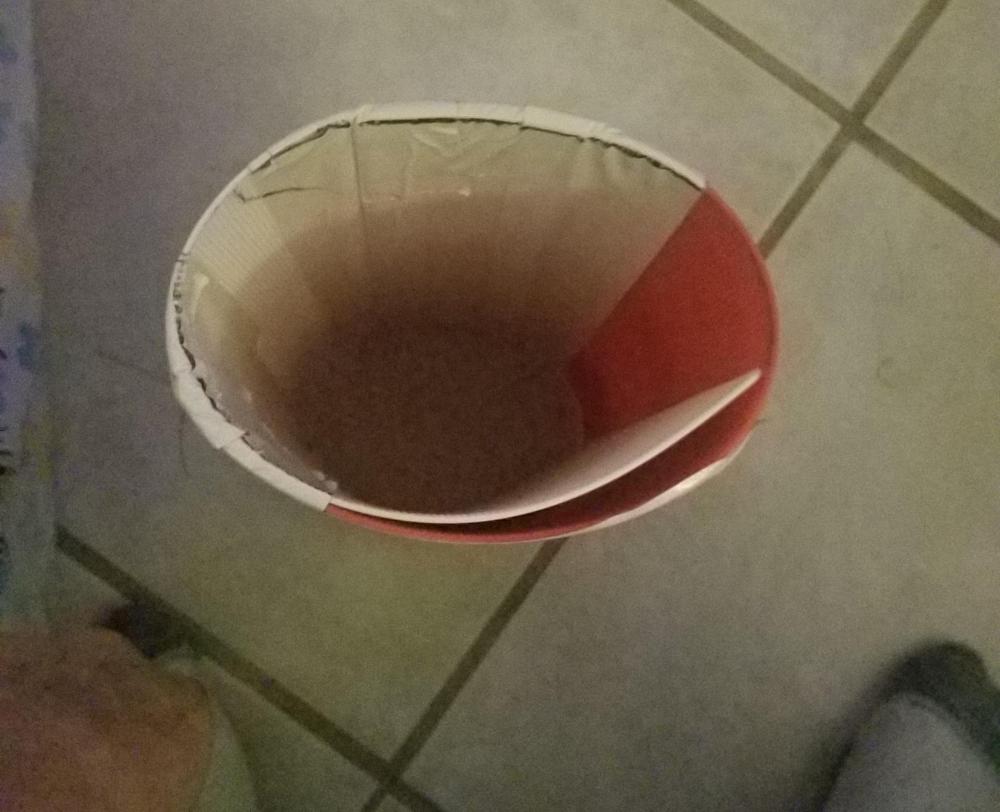

and now she is complete final side done she is about to go into her bag till thursday or friday. o and that's just the tube inserted to keep same shape on this end does not go to bottom that's the bottom with the vinyl on it.

-

can also use the inside of the tube when done as a fire brick form and then have a fire brick that fits in exactly to your curve of wall and lose no space

-

pat I am very new but for my form I used 2 flexible cutting boards inserted wooden dowels to the thickness I wanted of kastolite. then inserted the 2 cutting boards rolled into a tube released them inside the tube the dowels kept them at equal distance them taped that with duct tape. then mounted that tube onto a piece of wood and slid forge down the form. I am about to pull it from the form now but here are my pics. if plastic tube. then tapped in kol. probally could have made thinner but I am happy for 2nd try

thanks Frosty he helped with plans mine was not as easy as his lol

here is the rest of the form all 8 did was duxt tape the inside of form onto board. the tube and board were adhered with vinyl wall sticker sheets KOL peeled right away from form all I did was cut my duct tape a little so I could take a pair of plyers and curl the inside of the plastic cutting board away a tiny bit as soon as air got in I pulled it right out. just need to do the other side once done posting here. last pic is side I need finish was on board.

-

nice work sir. S hooks are great as well as the hammer. motivation just pouring in I love it.

-

mine is the Hells Forge model it was a gift so I cant complain. it will be perfect

-

mine is a single burner limited space but it will do I am so excited

-

friday I hope to fire it up. tomorrow get home from work gently slide from form flip and do otherside then back in bag till thursday.

-

-

nice blades. getting ready to do forge day didnt fo as 0lanned but when do they.

-

I do like the way that looks nicely done.

-

he will be very pleased. and thanks for the info keeps me motivated.

-

when I learn enough I will absolutely be trying that. lol just keep looking at it.

What did you do in the shop today?

in Blacksmithing, General Discussion

Posted

apreciate that. think I am about to head back out. was working on drawing out and squaring off was going to make an s hook then realized the thickness of my horn and enjoyed curling it up. after I curled it the metal spoke to me and said draw out a little more at the neck bend slightly and flatten and it will hold a coat. letter opener was just me seeing what I could do at sort of a knife shape but man does it get hard when metal gets thin.