Flynn

-

Posts

107 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Flynn

-

-

Hey, congratulations on finding a great piece of history. I ended up selling mine to another collector as I didn't find it as usable as a standard vise, as the handle stuck out whenever I'd have something clamped. But it may just have been less familiar to me so I wasn't used to it. Either way, I'm happy and the other collector was VERY happy. :)

-

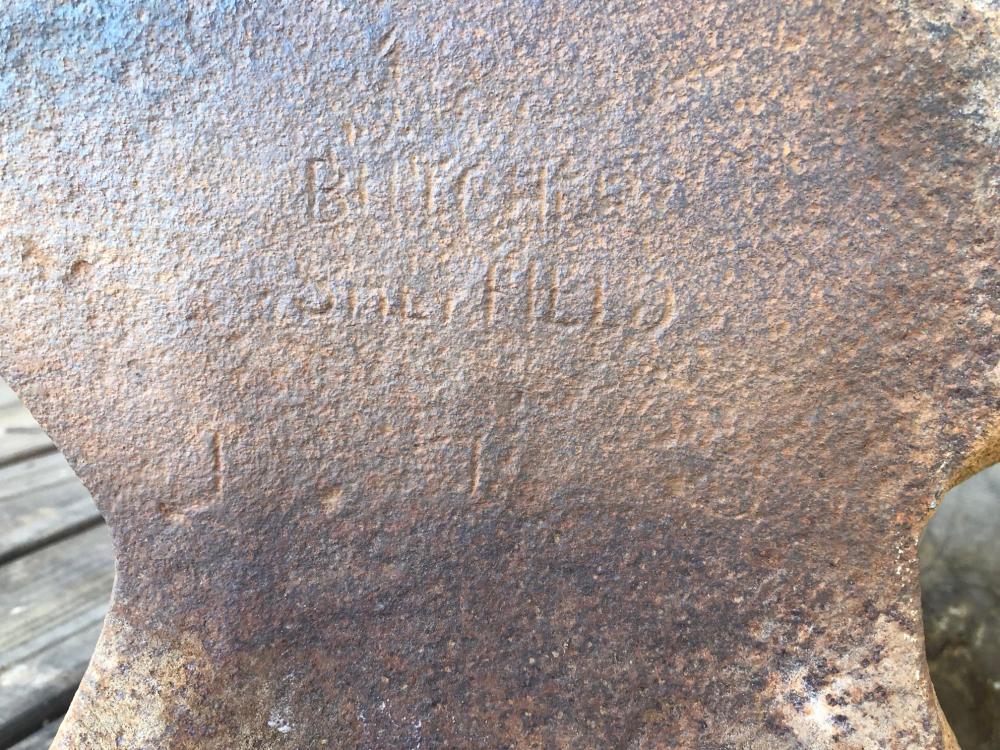

Just picked up this fellow in the Tennessee mountains. Only markings I can make out are Butcher/Sheffield, and 1 1 ? for the weight. I'd estimate it at 155lbs or so. Anyone heard of a Butcher brand before? Is it a Mousehole manufactured under a different name? It looks like one, but I don't see the heavy dots between the weight markings, but it's got the ridge under the horn and the general shape is close. Thoughts?

-

I had thought the riveted plate was more common with German-made post vises, but that's based on very limited information. Either way, I love the look of this one and was excited to find it.

-

Interesting! I had not thought of that, but it's certainly possible. I need to get it cleaned up so I can see if there are any other markings. So far this is it though.

-

-

Yep, Blackjack was one of the labels made by Hay Budden. Hope you had a great weekend!

-

It's all good, Frosty!

-

Hey Frosty, you're right about being patient. I was mostly kidding, but now realize that had no way to come through. I was just surprised when I hadn't seen anything before now and commented without thinking.

This one is for sale online and I don't have access to better pics. I love the history and construction methods of anvils.

And after some sleep and fresh eyes, I can make out that it says ****FACTUR*NG, which confirms for me that it's a Hay Budden. Thanks and have a wonderful day with your family! -

Man, nobody has a guess? No one at all???

-

I'm starting to feel back for only remembering to come back over here when I have an anvil I can't identify. I'll try to do better about that!

But here's one I'm stumped on. I've left the photo with the lettering full sized to help with identification. Mods can re-size it if that's not ok. At first I thought it said Blackjack, but now it looks more like Facturass. I have no idea. Sadly I don't have any more photos or information, this is from an online auction. My gut says it's a rebranded Hay Budden with that high waist and the shape of the base of the horn, but I can't find any record of markings that would match up. Thanks in advance for any ideas.-Flynn

-

Interesting, good ideas!

The confusing part to me is that the jaws are obviously made to hold something nearly flat, not a large piece like you'd use a power hammer for. So maybe large sheet work.

-

-

I am right with you, George... A few weeks ago I was minutes late to get a 242# Hay Budden anvil, and the guy that beat me to it had no intention of using it. He wasn't even a flipper, he just thought they were cool and wanted to display it in his man-cave. Broke my heart, it was a beautiful anvil.

Oh, yeah. And the nice lady only wanted $300 for it.

-

I absolutely get it, Frosty. For me I am a hobby smith and make different things as I'm inspired to do so, but my real passion is collecting old rusty tools and repairing/cleaning them up to be used again. Learning all the history of my tools is what gives me the fizz if you know what I mean. I know it's not important as the usability of the anvil, the history just what makes me happy about having a tool that is centuries old.

I'm hoping to have a call with the current owners that bought out Butt's & Ordway and maybe getting the anvil back to them for a display in the storefront. If it were my storefront, I would think that would just be the coolest thing in the world.

Or heck, apparently they make hydraulic presses. Maybe they'd like to arrange a trade!

-

IronDragon, I found this comment on another forum in reference to another American Wrought Anvil (Not the Horseshoe label):

"That is quite the rarity! According to Anvils in America (the only reference book on anvils), that is a product of the American Wrought Anvil Co. of Brooklyn, New York. The company seems to have been founded in 1899 by Walter Ring, the former Secretary-Treasurer of the Hay-Budden Manufacturing Company, the famous anvil maker from Brooklyn. He apparently had a difference of opinion with Mr. Hay, and started his own company to compete. The company seems to have stopped making anvils around 1911. Mr. Postman, author of Anvils in America, says they are very good anvils.The stamps indicate that one weighed 127 lbs when new. The body is wrought iron, forged from a single block in a closed-die press (Ring patented that in 1908) with a high carbon steel face plate. You can see the line between the iron body and steel face in that picture just to the left of the step. The face is about 3/8" thick. That is the only hard part of the anvil, and it's only hard for about 1/8" deep, so don't mess with it! "

I'm still researching to see if I can verify his statements, but haven't gotten there yet.

JHCC, the company is still listed on Google Maps with a phone number so I gave them a call. They purchased the Butts & Ordway company at some point and the person I spoke with said that a gentleman name Andy would be very interested in speaking with me. I've left him a voicemail, we'll see if he gets back to me.

-

You find yourself buying a lot of whatever it is your wife collects (plants, delft vases, etc) because you're afraid to come home without something for her when you've bought another anvil/vise/hammer/hardy tool for yourself.

-

-

No, the base was flat, no indention. I saw someone else speculating that they were made by American Wrought based on one of Postman's comments, but I'm not familiar enough with that maker to judge. After looking at some photos online, it certainly looks like a possibility.

-

Just picked up this fella the other day. Just one mention of them in AiA, but it looks like the company is actually still in business just outside of Boston. I may contact them and see if they have any more information on when they were made, and by whom. Anyone else have one or know more about them?

-

Well, I was vaguely excited to take a torch to it and dump it in the creek, but you spoilsports have convinced me not to.

I've already listed it up for sale (and explained the issues) for just enough to cover my expenses with it.

-

It's certainly possible... I had assumed it was from the welding, but who knows. The last owner didn't know it's history.

-

-

Well, I don't have any info on it aside from it being an Isaac Hill. I don't know the construction method for Isaac Hill anvils, but they have handling holes and were made prior to 1850, so I assume they have a hardened steel face and a wrought body. That is just from general knowledge about anvils, though. I did assume that the folks that would know about heat treating anvils would also know these same things, so I didn't think it was valuable info.

For this specific anvil, I don't know what type of steel Hill used for the face. I don't know how much of the face is original and how much is weld. I don't know what type of welding was done. I can go get a pic a little later, but like I said, it won't add much to the conversation since we already know the maker.

Thanks for bringing up the Leidenfrost effect, I had not though of that and my creek does not have enough flow to overcome it where I'd be able to use the tractor to maneuver it. I'll probably just clean it up and list it for cheap and educate the buyer on what they're getting.

-

The pics won’t be real helpful... the previous owner ground it all over to ‘clean it up’, and the edges show some weld marks. The welds appear to be done by a decent welder, but there’s no rebound to the face. So right now I have an extremely effective doorstop.

I have no idea what steel the face is, nor do I know what steel the welder used. I honestly don’t need this anvil, and I told the previous owner about the issues before I bought it for under a dollar/pound.

Worst case, I can put it out as a yard decoration. Just thought it might be worth trying to harden it rather than let it go to waste.

Stephens Lever Vise

in Vises

Posted

That's going to be a tough fix, I'm sorry! I'd say your only real option would be to build up the area with weld and then carefully file the teeth back into place. Maybe somebody smarter than me will offer a better option though!