Flynn

-

Posts

107 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Flynn

-

-

-

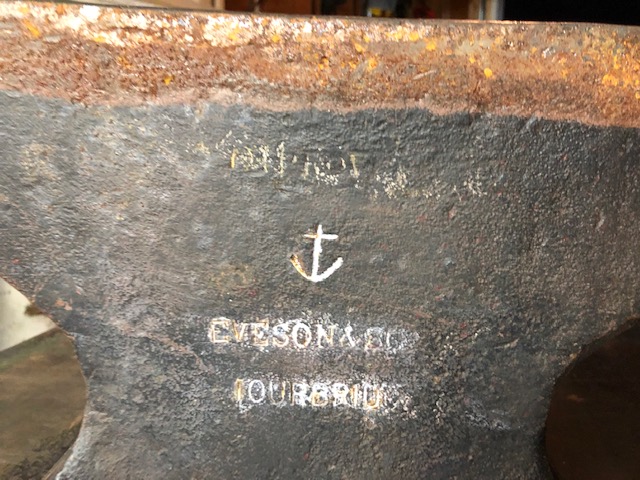

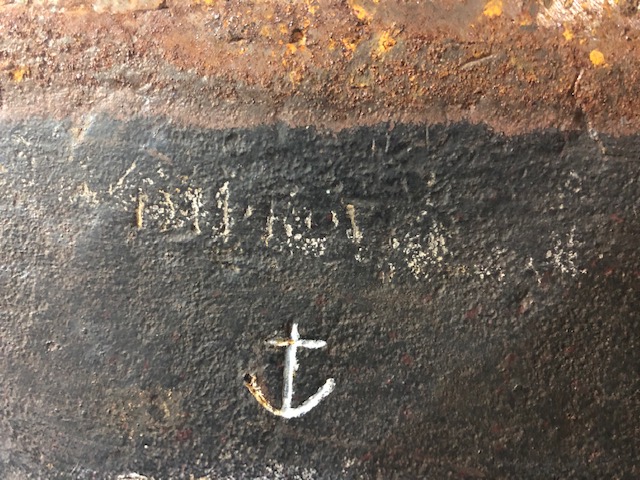

Oh, that's what it says below Eveson & Sons. I'm not sure what it says above the anchor.

-

So it turns out I'm an anvil collector. Who knew?

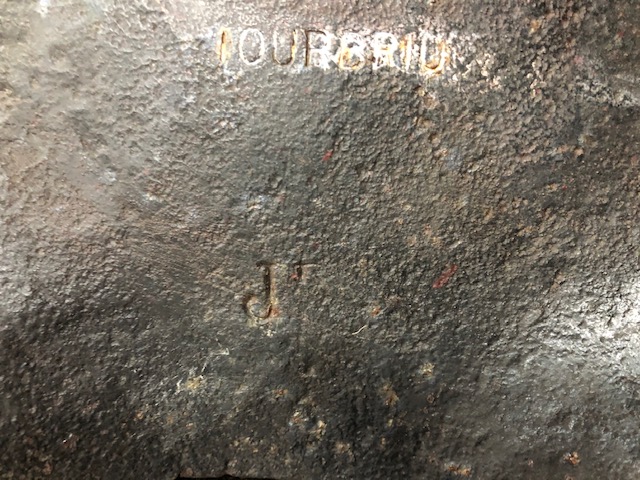

Just picked up this 195# (1 2 27) Eveson & Sons:

This one appears to have been welded across the face and along one edge. The rebound is good and consistent everywhere, though, and the tone of the ring doesn't change either. I suspect the repair was done right and I'm not concerned with it. I've found very little info on Eveson & Sons, though. I know they were manufacturing in the mid-1800s and it looks like two of the sons took over the business in 1855. Does anyone have any more info on them, or know how to date this one?

The text above the anchor might be DH ROV or something close to it. Or maybe something completely different.

-

-

Thank you so much for the info! Very much appreciated.

-

Yep, the rebound is fantastic. If you wouldn't mind looking up what you can in AIA, I would appreciate it. Trying to figure out a little more info on it since it doesn't have any serial numbers and the Trenton logo is missing.

-

I think I just need to give in and get myself a copy of Anvils in America.

I'll get some better shots of the feet and a shot of the base tomorrow, if I can make it out to the garage after the snow buries us. Anybody else up here in New Hampshire?

I'll get some better shots of the feet and a shot of the base tomorrow, if I can make it out to the garage after the snow buries us. Anybody else up here in New Hampshire?

-

No, no sign of anything above the Solid Wrought marking.

Maybe it was ground off? The Trenton's I've seen have had the weight listed on the front feet rather than the side, but I'm far from an expert.

-

So there I was. In a barn in rural New Hampshire browsing around while I was buying up a cart for the workshop I saw online. He told me he was moving so everything was for sale. I immediately whipped out my TPAAAT and asked if he had any anvils hiding in the barn. Lo and behold, he shows me this.

He said he already had an offer of $250, but didn't know when or if the guy would come get it. I went straight to the bank and came right back with $250. Just got home. I think it's a Peter Wright based on the shape and the "Solid Wrought" stamp. Can anyone confirm and give me an idea of the year to satisfy my curiosity? The only other marking on it is a 7 stamped on the other side, which I assume is an inspector's mark.

Any information about it would be appreciated.

Thanks in advance!

-

I think it's a Badger. The body and horn aren't the right proportions for a Vulcan, and the Vulcan logo would be large and proud on the side. I've never seen a Vulcan without the big logo on the side.

Oh, one more thing (edited). I am pretty sure Vulcan's have a 1/4 inch plate on top. If the faceplate is thicker than that, it might also be an indicator.

-

Yep, that's why I need help figuring this one out.

I haven't found any other examples of this numbering pattern... Maybe that 8 is actually a 2? I'm gonna go look at it again.

I haven't found any other examples of this numbering pattern... Maybe that 8 is actually a 2? I'm gonna go look at it again.

Yep, I think that might be a 2, with some unfortunately placed dimples making it look like an 8.

So that would make it 209 209 or 209 200.

-

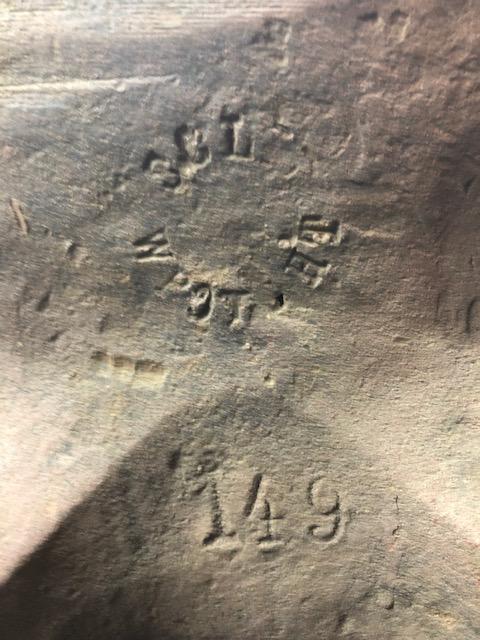

FWIW, I think the last number on the anvil is a 9 rather than a zero. It's too narrow between the outside edges compared to the zero next to it, and the visible curve on the left looks like a tighter circle than a zero. So if we guess that the serial number is 809 209, is anyone able to date that?

Thanks again for the help and the terrible jokes!

-

Based on what IronDragon said above, I'm sure it's 100 lbs (and not very worried about it). And I don't even own a bathroom scale. Weight is just a number, right?

-

Hi all,

I recently picked up a Trenton Anvil in the hundred pound range. I don't have a scale to weigh it, but it's definitely in that ballpark. I can't quite make out all the markings and the spacing seems very odd on the serial number. I tried chalk and a few other methods to make them stand out and this is the best I got.

?60 8 09 20? If I had to guess, I'd say it's R60 809 209 but that is very likely wrong. What do you folks think?

-

Another thing that may or may not help you out...

Are there any other smiths near you? Could you go in together and share cost?

Is there a maker-space close enough by that you could rent time on a power hammer or press there?

I've found there is usually a smithy set up to teach classes pretty close by where I've lived. Reach out and contact them, they may let you come and use their shop in exchange for work or for an hourly rate.

-

Sure, I ask mainly out of curiosity. That is a pretty press you've got!

-

Hi all, I just joined and was wondering if anyone knew where I could find info on a Perkins #4 flypress. I just picked on up and got it into my shop, but I've not had any luck finding info on them such as manufacturing date, actual press force (I've seen that they are larger and heavier than other presses with higher numbers), etc. Any help would be appreciated.

P.S. it was a xxxx of a job getting that thing into place in the shop, but it fits like it was made to go there!

Thanks!

.thumb.jpg.3c878e394624d0c50584e431b3112a9b.jpg)

Milling machine id?

in MIlls, Milling machines, etc

Posted

The head doesn't look adjustable to me, so I was guessing knee mill as well. I could definitely use some education here, I don't know much about mills but would like to add a small one to my shop and learn.

The seller is looking to see if she can get me more photos and the make/model, and I think I could probably get it for around $500. I don't currently have 3-phase power, but if the price is right I could make that happen too.