Tokum

Members-

Posts

17 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Tokum

-

Thanks for the replies. The jaws are 4 1/2 wide. As far as the cart, i think it's just a hand truck made by J&k out of Columbus Ohio, not Columbia. The conversion was done very long time ago so it still looks period correct. Gonna take some time and restore it. Thanks, Art

-

Finally got back to this posting. Watched the video. Yes, very eye opening. I still have both vises and I do agree that the wider jaws and gap would lend itself to more flexibility regarding grabbing on to things.

-

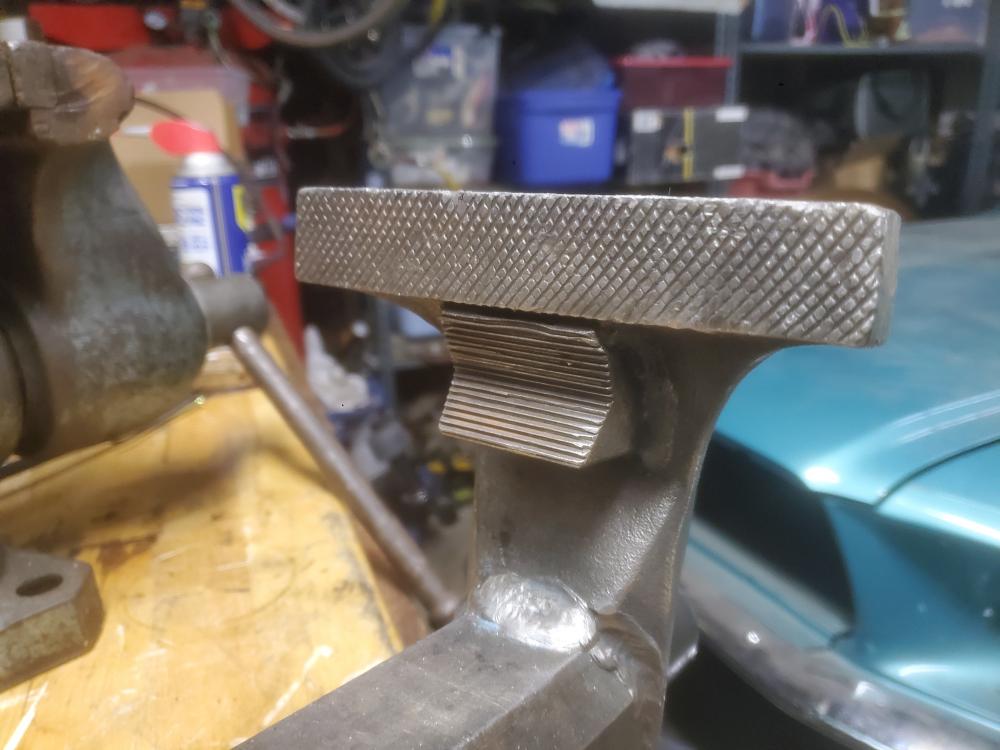

2 part question for y'all. I found myself at a yard sale this weekend and saw a unique vise. Neither I or the person selling knew how it worked initially. Long story short. When lever is in the vertical position, the vise opens and closes freely by hand. When you have your item( bar,pipe,wood, whatever) in the vise, you push the movable jaw up against item, then push back on the handle, the jaw then tightens up and locks down. To release, simply pull the handle back to vertical. I saw a posting here on the same vise but nobody knew much about it and that was almost 10 years ago. Hoping someone could provide a little more info. I don't really need another vise but the uniqueness has me on the fence whether to keep it or sell to my cousin Secondly. I also snatched up a vintage acetylene cart. After I started to clean it up a little I noticed a burned in manufacturer stamp. Made by K &J in Columbia Ohio. Tried looking for info in that as well but can't find any. I know the cart isn't vise related but any direction anyone can give me would be awesome.

-

Thanks for the input. As I was making this post, taking pics of each, I started to lean towards the Wilton because, as stated, the replaceable jaws, enclosed box, ext. I was also noticing the 4 point mounting holes on the Wilton vs the 3 point system on the Ridgid. I highly doubt I will ever put either one in enough stress to get close to a failure point but looks like the Wilton is taking the lead.

-

I have to pick one of these vises. I know Wiltons have a great history. This vise was made in 89 so its not "vintage". The Ridgid is forged steel and has a nice sleek look to it. Opens longer ( 10 in vs 6 1/2 ish on Wilton), but the flip side is it also extends further out the back. The handle is quite a bit longer. The Wilton is ductile iron. Both the main jaws and pipe jaws on the Ridgid all one unit. The main jaws and pipe jaws on Wilton are replaceable. The striking surface on back of Ridgid is about 4 in square. The wilton is about 3 1/2 in square. I don't want to choose the Wilton just because it's a Wilton or because everyone else has one.

-

I got anvil off the base. It actually did make a difference in the rebound. Not a night difference but noticeable. The bigger difference was sound wise. It rings much louder now. It does have a light smearing of oil/lubricant. I dont think enough to make a difference but I'll wipe it down tomorrow and see what that does. I wouldn't mind recording it and maybe posting on YouTube then adding the link here. If anyone would be interested. The base was made from some sort of soft wood as the core. Some plywood for the sides. Mounted to some small metal wheels. Wasn't very solid.

-

Thanks fellas I'm hoping to find some time later today or tomorrow to play around with it and I'll post the latest. I did test most of the face and closer to the horn seemed best It didn't have a great ring either. I personally like my fisher because of the lack of the ring but the trenton wasn't quiet like a fisher or vulcan nor does it ring like a HB. Pw. Brooks. The more I was thinking about it the more I'm thinking it's the base. Yes, the face is in great shape and such a large surface is really nice. The face alone is 22 in × 5 in so that's what attracted me to it in the first place. Thanks again for the feedback.

-

Hi all. I just picked up this good looking 345lb Trenton with a serial number of 205735. Because it looked so good,I just paid the man and ran like I stole a candy bar. Once I got home, I busted out the old ball bearing excited to see the rebound.. Wah-wah-wahhhhh... very surprised, very disappointed, very shocked. I've had/have a few other brands HB, Fisher, Peter Wright, Brooks, Vulcan. I know some say Vulcans aren't all that but the Vulcan i had out-rebounded this trenton by a mile. I know rebound tests aren't the end all but I was shocked nonetheless. I must mention that the anvil was on a homemade base that I cant say is a solid build or a major factor in poor rebound. I plan to take off base and put on solid surface and retest. Is low rebound common on Trentons? And would greatly appreciate info on serial number and production date. Thank you

-

What about decomposed granite?

Tokum replied to Tokum's topic in Stands for Anvils, Swage Blocks, etc

Lowering softly would make it nicer for sure, even if it is just an anvil. I remember our Class C RV that we used to have had simple valve that I used an ordinary bicycle pump to raise and lower a fully loaded 32 ft RV. Maybe something from the automotive airbag industry that's small and can be easily inflated/deflated manually? -

What about decomposed granite?

Tokum replied to Tokum's topic in Stands for Anvils, Swage Blocks, etc

Thanks for the feedback. I have a smaller Fisher I'll probably experiment with the stand for that one. Measured the sand filled stand, it is 14 in wide. These are the casters I'm hoping will work. They don't raise the unit a lot, just enough. There's even a pin you can theoretically remove the wheel if its gonna be in one spot for a long time. I plan to mount on the inside portion of the legs so they don't stick out further than the legs. -

I'm in the process of designing an anvil stand. Nothing ground breaking I know. Trying to blend different ideas and thinking of some of my own. I have 2 anvils, 3 actually but 2 big ones are part of this story. A 250 lb Fisher and a 325 lb HB. I live in the suburbs in Los Angeles so I don't have distance between neighbors or even my main living quarters for that matter. I initially picked the Fisher because of its quietessnes while still great rebound. I went to a purchase a slightly bigger, better condition Fisher recently because why not upgrade?? Upon arriving, the Fisher was sold the night before. Feeling horrible about the situation, the seller offered me a 325 HB with stand. I know the reputation of the HB's and their quality but my focus was based on as quiet an anvil as possible. He struck the HB and I was pleasantly surprised how quiet it was. The stand was a sand filled circular pipe. The pipe itself is probably 12-14 inches wide. A square bottom plate. The top plate is diamond plate cut little longer/wider and the edges bent up to lock in the base of the anvil. The anvil itself isn't tightened down but cant move side to side or front to back. He made me a deal I couldn't ( or at least didn't) refuse. Took it home. Unloaded anvil first. Wife came out & was expecting to see a nice quiet Fisher. I explained to her the stand made the HB quieter. Took the ball bearing out, dropped it. It had the standard "rings like a bell " ping. She wasn't too excited. I placed anvil on stand, dropped ball bearing again. Big difference. She was happier, not a lot but more than a little. My initial plan with my 250 fisher was to weld up a 3 post stand with some thick square tubing, use thick 3/4 in steel top plate. I found some heavy duty retractable casters I planned to weld to the inside legs of posts so that i can move the anvil as needed, then retract the casters so stand sits flat on the ground. I'm tight on space as most people are. I know the benefits of sand filled stands and now I can see/hear the difference first hand. The stand that came with the HB is a bit bulky. which also lends itself to me thinking of the 3 legged stand. The other idea I thought was to drill a hole thru the top plate, above each post & fill with sand. I know the bottom of the Fisher isn't completely flat and rocks a little on flat surface which is why I like tthe idea of some people putting their anvil in sand. Got me to think of welding some side walls to the top plate of the base so that i can lay down a thin layer of sand so the anvil has a solid contact without wobble. Then I was looking at my walk way at home. I used DG ( decomposed granite). It lays out like sand, compacts super tight and almost as hard as concrete after you wet it down. So I thought maybe fill the legs with sand, weld some edging on top plate, then put some DG on top plate instead of sand. The hard compacted dg could be vacuumed, brushed, etc without loosing material like loose sand would. I would probably do the same with the HB but since it already has a stand, that might give me something to compare to and see if its worth the extra work. Am I overthrowing this build?

-

Yes, the bottom has a closed ended u shaped hole. It appears it would have 2 be mounted to a horizontal fitting/pipe. The spring inside the vise isn't strong enough to push the jaws apart but can if it's mounted in the position the blue one is. A cole vise huh? Cool, thanks. I'll research Cole vises

-

Hi. I have this vise that I cant find any info on. I may need to use it to barter for other equipment but no idea of its value, importance, or even intended use, blacksmith, plumbing, woodworking, etc. I know its clearly not intended for woodworking but you get the idea. It opens and closes freely. I took it apart and cleaned up after these pics. The pic of the blue one is just a random internet pic.

-

Thanks for all the feedback. I'll hold on to the Fisher. Someone within my circle just told me about another anvil! I had put out the word to any and all. This other one is 64 kg Brooks England anvil. But condition is unknown at this time

-

Thank you. That's kind of what what my gut was telling me, to lean towards the smaller but cleaner Fisher. The Fisher sort of speaks to me only because its little thinner horn. But then again, I don't know if the horn of a bigger Fisher, equal in lbs to the Vulcan, would have same girth or still be more streamlined I also thought of keeping both and giving them each a nice working test. I'm still assembling /accquiring my toys but I will definitely be posting my work for critique. I made a cpl kitchen knives out of bar stock in the meantime but that was just cutting/grinding/shaping.

-

Thank you for the feedback. They were both within my budget and virtually the same price. I went ahead and picked up both figuring ( or hoping) I could just sell the one I don't use. Here are some pics. First 2 or 3 will be the vulcan, then the fisher. The pic of them both misleading as the vulcan is on top of brick half wall & the fisher on the floor, i didn't take a good side by side pic yet.

-

All things being the same, quality, condition, stand, placement, barometric pressure, etc ,,,, should i go with 120 lb fisher or slightly bigger 150 lb vulcan? I apologize if this topic has been discussed but I cant find it if it's already been discussed. I did a rebound test with ball bearing and as expected, the fisher has higher rebound. Im naturally a newbie and will be focusing on knives for a bit. Thank you