-

Posts

85 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by ADHD-forge

-

-

-

-

i'm wondering how you folks deal with long stock (2m or 6 feet) on the anvil . i was working on a camping tripod today and had a hard time forging a point on the end of the pieces, i mean holding on and tilting the piece ( 15mm sqaure 2m long) to get a nice point was a p.i.t.a as it got very heavy in my hand trying to hold it in position on the anvil. do you guys use a stand or something els ? i'm just wondering how other people go about it.

-

not much forging going richt here now, major remodeling going on now. trying to set some major wrong's of the original contractor straight. the house was build in '56

i had to take the facade off because all the masonry was loose and the dit nog use the normal amount of tie-ins . but now we are going to insulate the back off the house and put in new windows to.

and i got a nice surprise when taking off the old roofing from the roof. there was hardly any slope on the roof and to raise the level of the roof they just put building debris on the concrete with a 2mm layer of cement

but today raised and sloped the roof to the richt level and slope so my roofing guy can insulate the roof and put on new roofing.

same for our back side of the house, we have a smal poch on the back off the house but the tiles where just layed in the dirt wit some cement and no slab underneath.

so i had to pour a new slab and need to insulate the floor and level it so i can put on some hardwood flooring.

pfff way to much crap to deal with, i'd rather be forging the cleanig up this mess.

-

so a couple of weeks ago i made a skillet and now i would like to make a sauce pan to go with it. but i'm not quite shore how to go about it, i found that when you want to raise the edge the whole thing goes daddy wompus and flexes and moves all over the place and you don't know where to start first. seen as the pan would be about 8cm deep and have a bottom diameter of about 16cm.

would i try and "roll" the edge over my stake or first make a depression with my hydraulic press and the finish it over the stake? i'm afraid the because of the high edge it will crumple. any thoughts, tips or reference material i should look in to ?

thanks

-

-

-

-

Made a stand for my press and lifted it on the stand, its bigger than anticipated. Anyone had that happen before ;). As i dont have a gantry at home a borrowed some scaffolding from work to lift that bad boy on to its stand ( she's around 200kg 400lb). The wheels wil be taken off when i get a new shop but for now she's gona sit there.

-

those look nice and heavy

-

band saw at work and a bit of filing

when i'm using them i realy need to use ear protection because they make a XXXX of a lot of high pitch noise when hitting them, i think a combination of the anvil and the tool together seen as its loos in the hardy hole.

-

On 5/15/2019 at 1:35 PM, Kozzy said:

IFI immutable laws of smithing:

indeed the truth

indeed the truth

-

i use it almost every time i'm forging. i only wish i made it a bit larger so i could fit lager stock. but works like a champ

-

looks realy nice!

-

-

Whats a gozintas frosty? Thats a word i've never heard before, i'm gona go out on a limb heren and you mean the posthole.

always good to learn some slang

always good to learn some slang

-

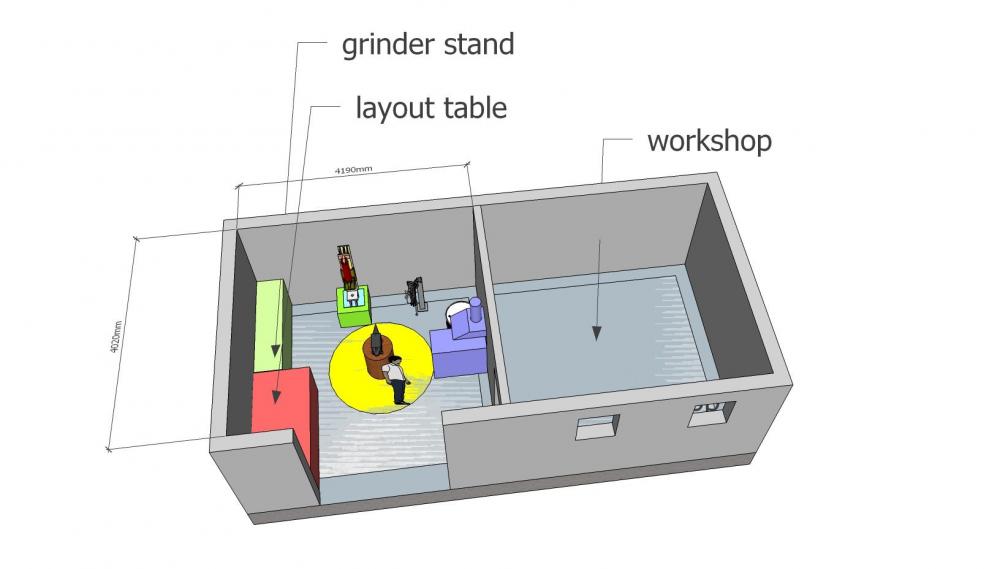

i was thinking of a square hole in the ground to mount a post that's interchangeable for either free standing vise of other tools like a bender or whatever i come up with

-

-

wow great stuff, i'm jealous of your setup

i've just got a cheap newtonian that i need to take out more

i've just got a cheap newtonian that i need to take out more

-

made some progress on the press this weekend and found a better power pack than the small one i bought.

still need to make a base for the bottom dies but i ran out of steel

time to go to work and look in the scrap bin

time to go to work and look in the scrap bin

standing it up was a challenge on its own she's got a lot of gravity to her! the plan is when she's finished i'll put her on the forging table in the back where the hole is cut.

the new power pack 2.2kw @ 220v 80L/min and max 250 bar pressure and the flow and pressure are controllable by adjusting the mirror, o also put in quick disconnects to the control valve.

all connected up and ready to fill the tank with oil and give her test run, but for now i'm gonna have cover it up and find some time in the next couple off weeks to continue working on the press and some home inprovement.

-

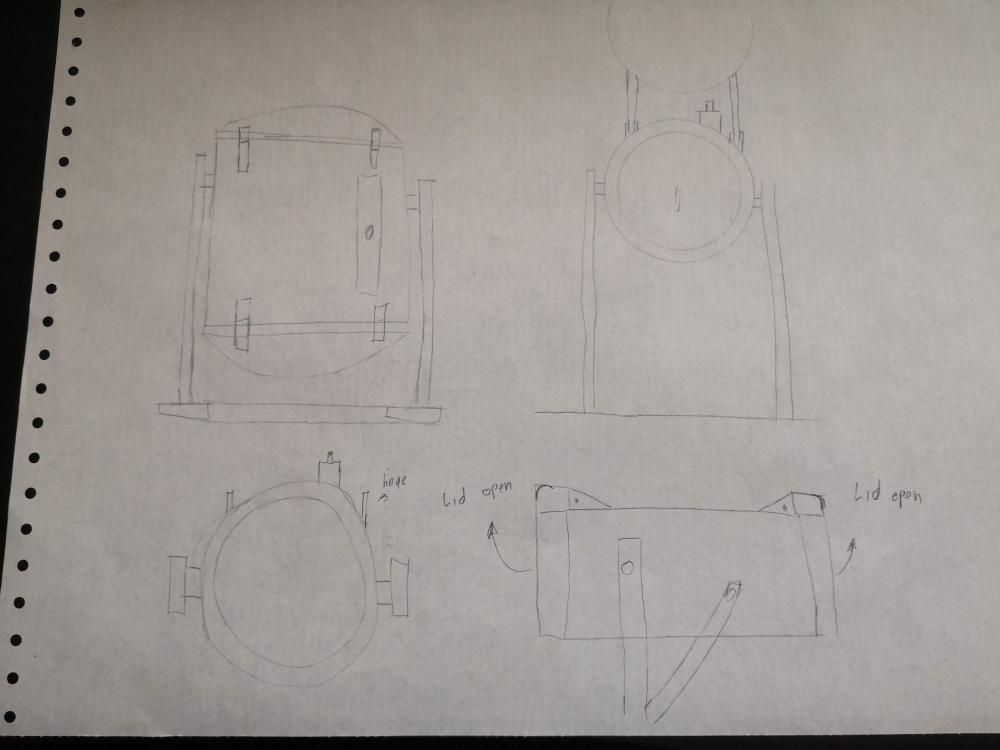

i like this concept of a ribbon burner butt i'm wondering if one could use the burner to make a foundry burner? i have this idea in my head for a forge for dual use. a foundry that you can tip over and would become a forge. anyone familiair with the concept or is it just a mad idea? i'm just thinking i could be a good concept as u would have 1 forge instead of 2 bulky forges that would take a lot of valuable space. and if it cuts back on noise and gas usage it would be very nice indeed. or is this just ramblings of a mad man

this i just a rough crappy sketch

-

-

-

Fixing up a post vise as a gift for my blacksmith FIL

in Vises

Posted

you should add mechanics as well