psacustomcreations

Members-

Posts

57 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by psacustomcreations

-

What did you do in the shop today?

psacustomcreations replied to Mark Ling's topic in Blacksmithing, General Discussion

I added LED lights to my forge area and storage container today. That makes it a lot nicer in there. I also had no specific goal in mind today at the forge so just worked on bends using some bar I had already tapered, coiling a piece of 1/4" round bar and then making a candy cane with some twisted 3/16" square and round bar. The long leg of the cane should have been another inch or so longer. The piece was 7 inches long to start with. I brushed on some wax then used the brass brush. That combination made a darker finish that the previous one using just a brass brush. This is the first time I have tried that. -

It followed me home

psacustomcreations replied to Glenn's topic in Blacksmithing, General Discussion

-

What did you do in the shop today?

psacustomcreations replied to Mark Ling's topic in Blacksmithing, General Discussion

Thanks. We had a good time yesterday but the rain and cold got the better of us. When you have the door open and it is 35 degrees and raining outside it still just sucks. I had an errant strike with the punch on the hook but definitely learned a bit. -

The Importance of PPE

psacustomcreations replied to psacustomcreations's topic in Personal Protection Equipment

For what its worth, I like to use these Pyramex full lens magnifying safety glasses. I have them in 1.5 for an arms length at the forge, 2.0 for a bit closer, 2.5 for MIG welding, and 3.00 for TIG welding. If the link is not allowed, please let me know or remove it. Commercial link removed I have never been able to get used to bifocals so I like the full lens style glasses. I will also use a 1.5 on my face glasses plus a 1.5 cheater in the welding hood. The nice thing about the glasses is that I can still wear a half mask respirator. I also have the Bionix face shield with the clear, shade 3, and shade 5 for plasma cutting. When I am doing some work on the metal lathe where I am scraping old paint off tanks and chips and dust are flying everywhere, I have a 3M full face mask with filters. -

What did you do in the shop today?

psacustomcreations replied to Mark Ling's topic in Blacksmithing, General Discussion

I spent a few hours yesterday with a friend teaching me a bit more. We did tapers, "S" hooks, braids, and twists. That is the first pic. Today I continued that and welded a few pieces of 1/4 round bar and some 1/4" square bar together then twisted. I also practiced punching holes in a hook. -

What did you do in the shop today?

psacustomcreations replied to Mark Ling's topic in Blacksmithing, General Discussion

I have not spent much time at the forge the last couple of weeks. I forced myself to remove everything from my main shop and clean and organize it. A lot of it went into my 40 foot storage container. It feels good to have room to work and a clean shop. I also spent a few days putting ridgidizer and refractory on the door of the forge . The goal was to turn these pieces of 3/8" round bar into square bar and taper the ends. This was the first time I used my new 2 pound Mustad rounding hammer I got at Tractor Supply. It was also the first time I used tongs while working. Previously the square bar I was using was long enough that I didnt need tongs. I have a friend coming over tomorrow. He will teach me blacksmithing for a few hours and I will teach him TIG welding. Pointers or suggestions are always welcome. -

Show me your anvil

psacustomcreations replied to Glenn's topic in Anvils, Swage Blocks, and Mandrels

Thanks. I was very happy to get it for that price and in that condition. -

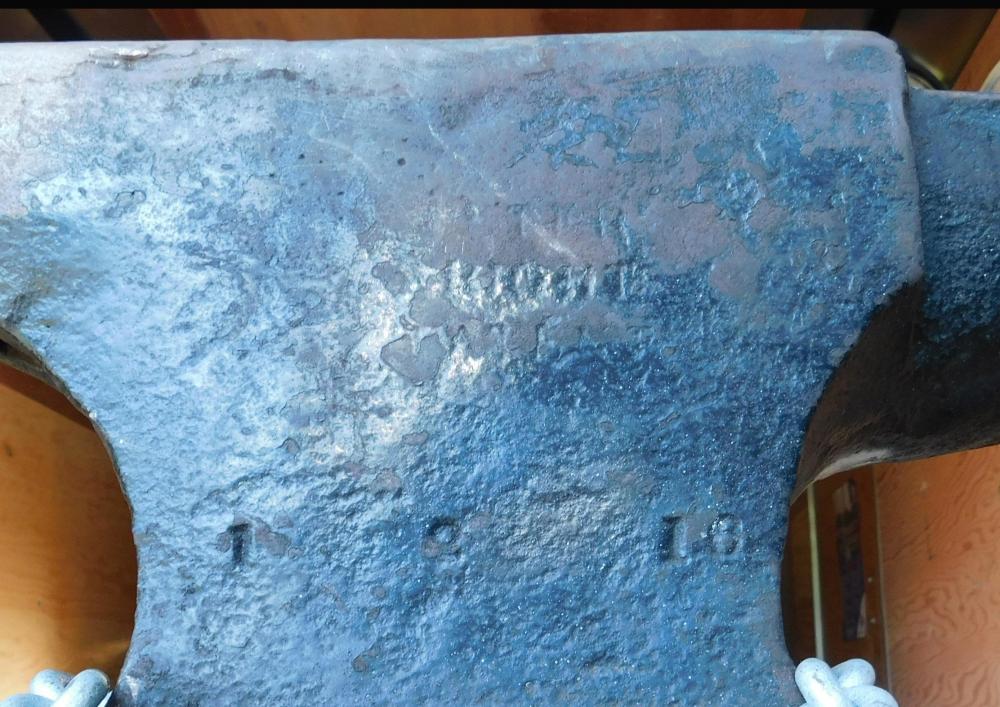

Show me your anvil

psacustomcreations replied to Glenn's topic in Anvils, Swage Blocks, and Mandrels

This is the Peter Wright I picked up earlier in the year for $500. I had made arrangements to buy this from the owner, but could not get it until after ABANA in Richmond. I still have it on the same chunk of wood but removed the bark. -

Here are a few of my larger bells plus a planet like sculpture that rotates and has a light and a dark side. I made these out of wood but I think a good smith (not me) could makes something like this out of copper or steel.

-

Craft vs. Art

psacustomcreations replied to George N. M.'s topic in The Business Side of Blacksmithing

Das, I do about 15 shows a year within about a 125 mile radius of where I live. I kind of draw the line at a 2 hour drive. I have a trailer I keep loaded with my items. Since it is all metal art, I have weighed it before and know that at a small show, I am moving about 1000-1200 pounds in and out of the trailer. At a larger show, it may be closer to 2000 pounds. My bigger bells will frequently weigh 175 to 225 pounds. I offer free delivery on items like that if they are within a short drive of the venue. I normally only do outside shows. This puts me at the mercy of the weather, but I can usually drive my truck and trailer pretty close to my spot. I also arrive very early so I don't have to deal with traffic in the venue or middle of the road. Once you start attending shows, talk to other vendors. I have created a list of all the shows I have attended and make notes of how I did, whether I will keep coming back or whether I will not return. I email that list to other vendors and we share information on a regular basis. Some I share with are selling completely different product lines so if they do well, it does not mean I will do well. You will still hear about shows you may never have heard of before. Booth photos and item photos will make or break whether you are allowed to attend. Try to have a cohesive and clean booth photo for submission. This area has been my downfall before since I make a variety of items like you. It can be hard to squeeze everything in for a show. For the submission photo, remove some of the excess and have neat display. Clean photos of your items showing details and the level of craftsmanship are also important. Do not be afraid to enter juried events. They usually want higher quality items and may have higher entrance fees but you have the chance to win awards. I have won Best in Show a couple of times because my items are unique like yours. If you are using re-purposed or recycled material, highlight that to the judge and on your entrance form. If you are using re-purposed items, don't be surprised if people offer to give you material. I have received hundreds of pounds of material for free just from attendees. I have also offered a slight discount if they offer me material. People seem willing to give away their items or scrap if they know it will be used again. Engage your customers and try to bring them into the booth or talk about the item. If they appear interested in a particular item, talk to them about how it may look in that spot in their home. One vendor I know makes items out of wine barrels, He makes really nice items and has won awards but just sits next to his cash box. If a customer comes in the booth, he sits there until they say they want to buy something . Pat -

Craft vs. Art

psacustomcreations replied to George N. M.'s topic in The Business Side of Blacksmithing

A story I heard, may or may not be true, goes along the lines of this. Picasso was sitting a cafe doodling on a napkin. When he got up to leave he crumbled up the napkin and was going to throw it away. Another customer asked if she could have the napkin. Picasso replied, "Sure, for $5,000." The customer gasped and said, "But it only took you 5 minutes and you were going to throw it away." Picasso told her, "It took me 40 years to learn how to do this in 5 minutes, plus I am Picasso." The point is that if you only charge for the time you invested, you may be short changing yourself for the years it took to learn how to do that plus the cost of the tools and equipment to do the job. If your current shop rate takes all that into account and you are comfortable charging shop rate continue to do so. -

What did you do in the shop today?

psacustomcreations replied to Mark Ling's topic in Blacksmithing, General Discussion

Square to octagon to round -

What did you do in the shop today?

psacustomcreations replied to Mark Ling's topic in Blacksmithing, General Discussion

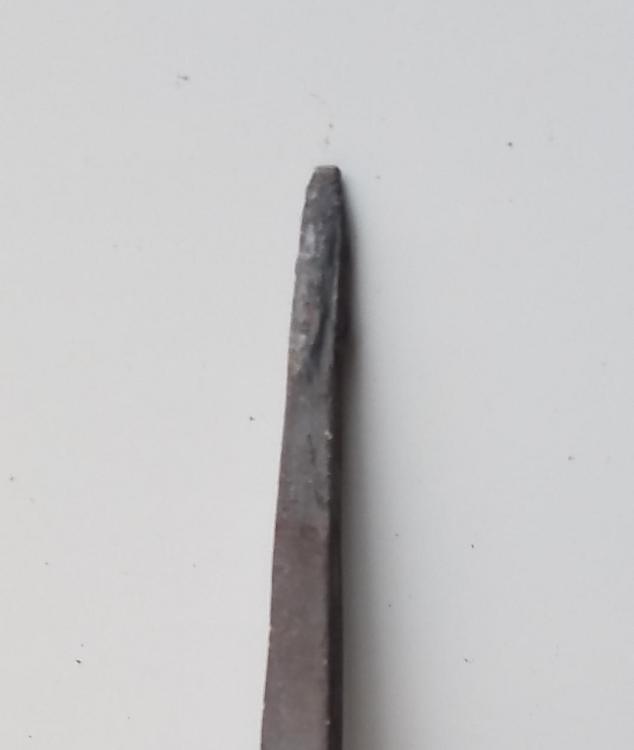

Todays goal was round tapers using the rounding hammer. I finally weighed this hammer and with the handle it is right at 4 pounds. Here is how the face looks after this session. Advice or thoughts on how I am using it? I know I need to clean up the face, but I also need a new handle on it. -

What did you do in the shop today?

psacustomcreations replied to Mark Ling's topic in Blacksmithing, General Discussion

Das, Since you asked about what I make, here are a few examples. 90 percent of my work is with scrap metal. -

What did you do in the shop today?

psacustomcreations replied to Mark Ling's topic in Blacksmithing, General Discussion

Neil, I started with short tapers then lengthed them the next session. The flexing and flopping around is exactly what happened to me. Thanks for the idea of leaving a lump for later. Pat -

What did you do in the shop today?

psacustomcreations replied to Mark Ling's topic in Blacksmithing, General Discussion

No reason for you to apologize and I apologize as well if I came across wrong. I am new here and people don't know what I do nor why I took up the trade. My metal work is similar to what you make. Thanks for the help. -

What did you do in the shop today?

psacustomcreations replied to Mark Ling's topic in Blacksmithing, General Discussion

Good idea, thanks -

What did you do in the shop today?

psacustomcreations replied to Mark Ling's topic in Blacksmithing, General Discussion

Das, I am one of those strange people that don't watch TV and have never seen an episode of Forged in Fire. Not that I have anything against those who are making knives. I just took up this skill for art and sculpture purposes. Some of the knives and swords I have seen here and other places are pieces of art and the makers are true artists of the trade. -

What did you do in the shop today?

psacustomcreations replied to Mark Ling's topic in Blacksmithing, General Discussion

Ok. Do you think it is from being too cold or poor hammer technique? -

What did you do in the shop today?

psacustomcreations replied to Mark Ling's topic in Blacksmithing, General Discussion

I should have posted this and asked yesterday. As I was making my tapers, the last half inch of one end split. I assume it was from working it too cold. I continued to heat and beat and it seems to have closed up but not fused/welded. With my limited skill/tools I also assume the best option is to cut off and start over. Is is possible to forge weld this back together and if so, how? I am thinking if this happened early in a project, cut and start over. But if the piece was cut to length and you were somewhat near completion, how do you save it? -

What did you do in the shop today?

psacustomcreations replied to Mark Ling's topic in Blacksmithing, General Discussion

Thanks. I need lots of practice but in time hope to be decent. -

What did you do in the shop today?

psacustomcreations replied to Mark Ling's topic in Blacksmithing, General Discussion

Today was a continuation of yesterday's taper practice. Based on the advice I received yesterday, I put a piece of 1/4" plywood on the anvil and hit that a few times to see how the hammer was actually hitting. Shown is the face of the hammer I am using. I measured yesterday's taper to see how long it became. Then I marked it again and continued the taper process. I taught myself MIG and TIG and know padding beads can be boring but it teaches the motion and consistency. I am trying to use the same thought for this craft. -

Craft vs. Art

psacustomcreations replied to George N. M.'s topic in The Business Side of Blacksmithing

While I am new at smithing, I have been selling my metal art online, at craft shows, and art shows for about 6 years. Each of the three venues are different and can command completely different prices for the same item. I will frequently change my prices based on the type of show I am at. I consider myself to be in the middle stages of shifting from crafts to art. The post above by Marc1 has many points I was going to address, so I will also add a few more thoughts and some of my experiences. What is your time worth and how to price items are difficult to answer questions for many artists. I try to make one off items art items but will also have a few lower priced craft items, where I may have multiples of that same item, as well in my booth. The cheapest item is about $20, the average price for other items is $150 or so and I also had items in the booth for $2,500. I have a good friend that also does metal art and he has plenty of items that are $20, an average of $100, and his most expensive item rarely goes over $300. At the end of each day we tell each other how much we made. It is common for us to have a similar total amount of sales, say $800, but where I sold 8 items, he sold 20. Who is more successful? I would say the one that spent less time in total. If I make a scrap metal sculpture that took 2 hours to make, cost $10 in materials and paint, but sold it for $150 while he sold 4 items that took 3 hours to make, cost $20 in materials and paint, and a total of $160 in sales, I like to think I came out ahead. I have a spreadsheet where I keep track of all my expenses and sales. I know how many of each type of item I have sold and the average selling price for each. If you are going to treat this as a hobby, you may think you don't need this, if you are serious about this as a business, you are crazy not to know this. Back to the art versus crafts. This year I attended a fine art show. The first thing I did was raise the price of the items in my booth. I had another metal artist who was a true craftsman and artists, tell me I had some high quality items, but my prices are still too low. I had raised the price of one of my larger pieces from $2,000 to $2,500. Two older couples walked by and looked at it and told me how much they liked it. A few hours later, one husband showed up and said that piece was killing him and he thought about it the whole time they were eating lunch.This goes back to Marc point about art creating a reaction. The husband purchased that piece without even asking about a discount or discussing the price. When I dropped it off, the new owner showed me his house that was fill of fine art. I was honored to have one of my pieces mixed in with that group. Attendees at art shows want to feel as if they own an exclusive piece. If they see that there are multiples of the same piece, no matter how good it looks, it comes across as mass produced and lost its uniqueness. I have made several items that are very similar, but each will have a bit of a twist. I will then only bring one of those items to a show and once that sells, grab the next one for another show. When you are trying to sell at shows, do you offer discounts? I have a 10% premium built into my prices so that if I have to offer that to make a sale, I will. It is common for people not to ask for the discount. In regards to art personalities versus "normal", that is also sometimes the experience the customer desires. -

What did you do in the shop today?

psacustomcreations replied to Mark Ling's topic in Blacksmithing, General Discussion

Thanks. I am still learning and did not know the details on the faces of the hammers. I will have to look at the face of the hammer I used, but I am pretty sure it is flat with almost no crown. I have a rounding hammer I used making the leaves last week. -

What did you do in the shop today?

psacustomcreations replied to Mark Ling's topic in Blacksmithing, General Discussion

This was my second session at the forge. I had made some leaves the other day and based on the advice of Vaughn from Three Rivers Forge I started making tapers. I watched a bunch of videos on making tapers while I was down at Fabtech and started to make some today. Vaughn mentioned working on consistency so I placed a center punch 1" from the end on all four sides of the four pieces of 1/2" square bar. This gave me a known reference point once I started working. I found that the taper started to twist a bit which I am assuming is from not holding the stock straight. I was heating two pieces at once and would alternate as they were ready. All work was done with a flat hammer. The pieces are in the order I made them. With the orange piece being the last one I made. I think some of the slop or twist may also be from getting a bit tired since I am new to this