-

Posts

14 -

Joined

-

Last visited

Contact Methods

-

Website URL

www.starlighttools.com

Profile Information

-

Gender

Male

-

Location

Nelson, BC, Canada

-

Interests

Metal Working, Photography

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

Double Horn vs Square Tail Anvils

Starlight Tools replied to Starlight Tools's topic in Anvils, Swage Blocks, and Mandrels

Foundryguy If you get to Nelson again, look us up! It is a gorgeous part of the country, very little manufacturing, but lots of tourism, and yes there are a couple of world class ski hills in the area. Walter -

Double Horn vs Square Tail Anvils

Starlight Tools replied to Starlight Tools's topic in Anvils, Swage Blocks, and Mandrels

Thanks Gang, it was narrowed down to two choices, the Holland Anvil or the Peddinghaus. The Peddinghaus was considerably less expensive after freight and import expenses were taken into concern. Ordered Oct 9, and it was delivered Oct 27. Which considering one inquiry I had made said they were on B/O in Canada until early spring caught me off guard with how fast it actually arrived. JLP, yup the Hardie and Pritchel holes both line up with the base of the anvil so it is not possible to pass long stock through them, so I will have to see if it is worth the effort to modify the base or not. Walter -

Double Horn vs Square Tail Anvils

Starlight Tools replied to Starlight Tools's topic in Anvils, Swage Blocks, and Mandrels

So I had a little puppy follow me home today. Hoping it will attract more, LOL Went with the Peddinghaus 275 Lbs Double Horn Anvil. Walter -

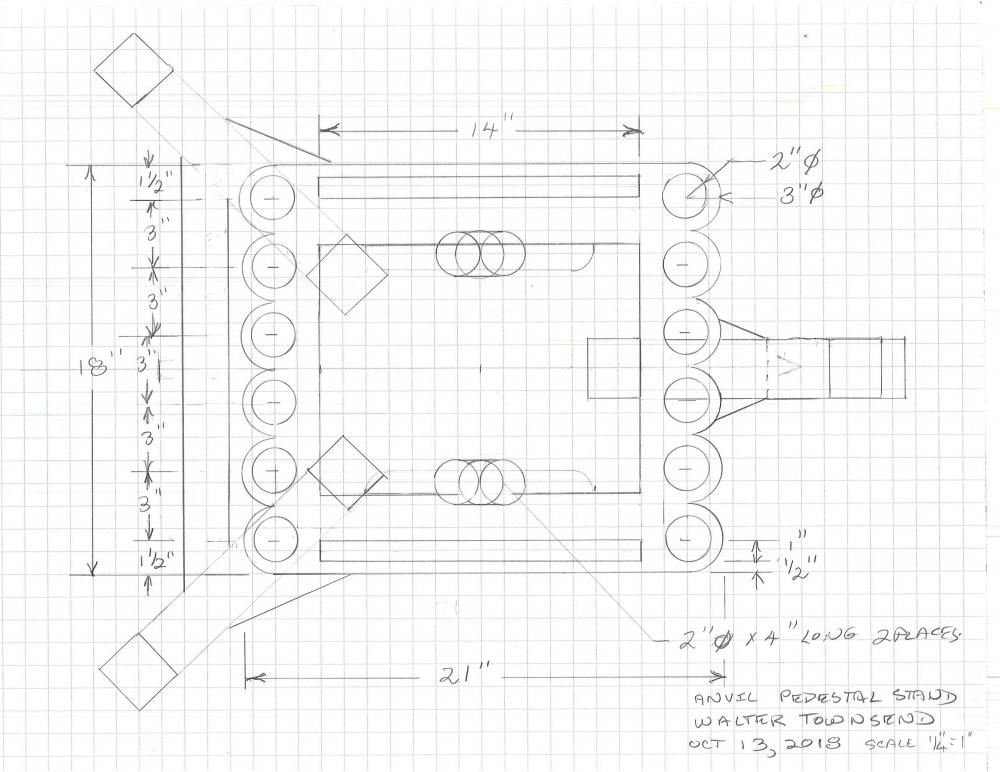

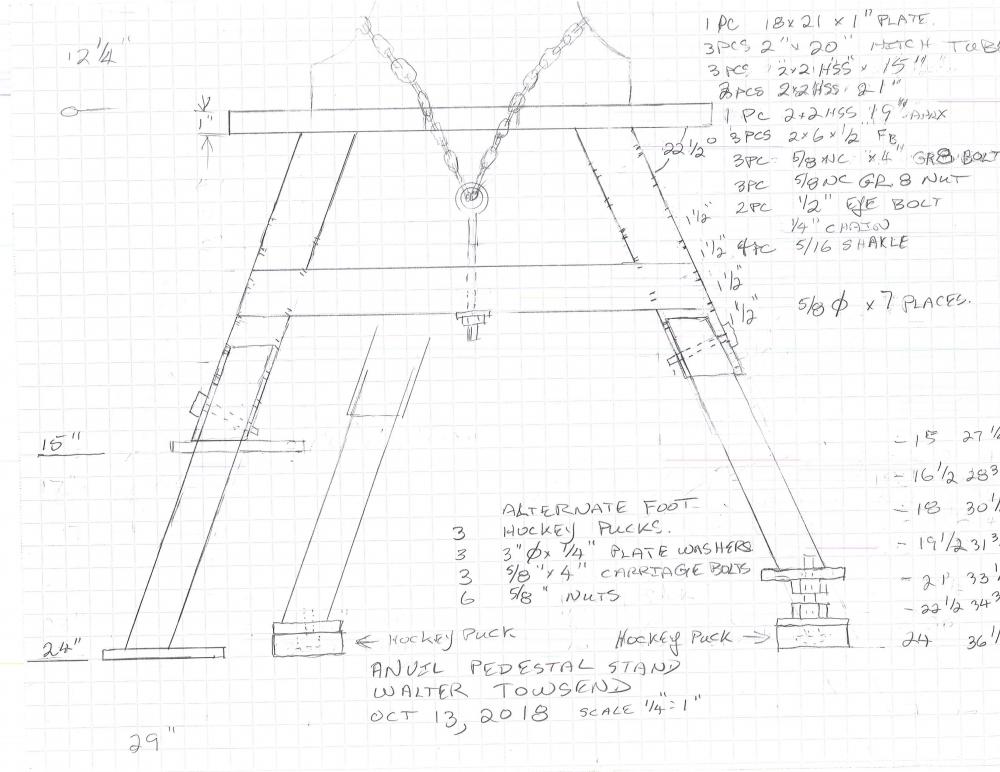

Show me your anvil stands

Starlight Tools replied to pkrankow's topic in Stands for Anvils, Swage Blocks, etc

Thanks There will be a hole directly under the hardie hole to pass stuff through, once I determine where the hardie hole will be located, as the anvil is not here yet, I can only work out the details that I have available, if the hardie hole is not directly in line with the feet as you have mentioned, which I would not be surprised if it is. The side slots are 1" wide so they can be used to hold tongs or to hold hardies. The basic concept for this stand was one that was posted on millerwelds.com It was made with 2x3 HSS and 1x3 HSS tubing with the 1" plate top and has four legs. I figured the three leg style would be more self leveling. I doubt this stand will bounce around as it will be well stiffened and made form fairly heavy material, all welded together. I will look at how to incorporate a swinging tray. Anybody attempted to drill out a hole under the Hardy on the new Peddinghaus design? I have drill bits that drill Hardened steel in the 42-65 Rockwell "C" range. Thanks Walter -

Show me your anvil stands

Starlight Tools replied to pkrankow's topic in Stands for Anvils, Swage Blocks, etc

Been trying to combine anvil stand styles I have found perusing the internet and come up with a design to build to support the anvil I am going to get. Aiming for a 275 Lbs but may end up larger. Any thoughts on the design I have come up with? Aim to use material I already have in inventory, 2" hitch Tube and 2" x 2" x 1/4 HSS Tubing to make an adjustable height stand. Which would put the top of a 12-1/4 in high anvil at between 27-1/4" to max height of 36-1/4" My "optimal" height by the closed fist knuckle loosley at the side is 29" I have three different foot options, Option one - 1/2" thick steel plate, 2" x 6", this allows the stand to be bolted down, but doubt it would be as it will be a finished concrete floor with in-floor heating. Option two - Hockey puck bolted to the bottom of the foot. These make excellent non slip feet and would protect the concrete floor. Option three - Hockey Puck leveling foot. I have used this design a lot and allows the stand to be adjusted for uneven floors. Thanks for your opinions. Walter -

Buzzkill, I agree, that is why I am working at building a new shop.

-

Every time I order a new machine tool, I request they send a floor stretcher with it. so far new tools arrive but no floor stretcher. I do the same with my kids, get them tools for Christmas and Birthday presents.

-

Hi all, just thought I would introduce myself, My name is Walter and I am a Tool-Aholic, I could change if I wanted to, but I don't. I am a millwright, welder, machinist, electronics technician and computer technician by trade. I run a tool repair shop in Nelson, BC, Canada. We repair tools both within and out of warranty for just about every brand of power tool available. We also offer welding and machining services. We have a small area of the shop that has some of the basic blacksmith tools, many of which have been pushed into storage so the shop can operate. We are looking at building a new shop and hope to have more room set aside for Smithing once the new shop gets built. Looking forward to getting to know you all. Walter

-

Double Horn vs Square Tail Anvils

Starlight Tools replied to Starlight Tools's topic in Anvils, Swage Blocks, and Mandrels

The Record Anvil is 620 Grams, or about 1-3/8 lbs. I purchased two of them when I worked at Home Hardware, so that would have been about 30 years ago, I gave dad one and kept the other. I know that mom still has dad's proudly displayed with her tape measure collection, he passed away in '97. These were a promotional item promoting BenchMark Tools, which was a Home Hardware House Brand. I have never used it as an anvil as I have a better chunks of RR Iron and countless blocks of steel that I can bounce a hammer off of. Marc1, it must be a rumour that Noah's Ark landed in Turkey, considering the age of many of the tools that come in for repair here, I'd swear it landed here in Canada. Sorry to the purists, yes I am in Canada so really we are on the other side of the world from Mt Ararat where Noah is supposed to have landed. Walter -

Starlight Tools changed their profile photo

-

Double Horn vs Square Tail Anvils

Starlight Tools replied to Starlight Tools's topic in Anvils, Swage Blocks, and Mandrels

-

Double Horn vs Square Tail Anvils

Starlight Tools replied to Starlight Tools's topic in Anvils, Swage Blocks, and Mandrels

I am located somewhere close to where Noah landed the ark. Much of the tooling in this area is about that vintage. A lot of mining in the early years, but it has never been much of an industrial town, and is now known more for tourism. I have upgraded the header to reflect my location which is Nelson, BC. This is a very artsy town and there is actually a blacksmith program at the local college. Matter of fact they used that shop in the last season of Amazing Race. As such, we have a vacuum in this area where it comes to blacksmith equipment. All the students are gobbling up the used equipment as soon as it comes available. Many have stated that they have had to travel great distances to get deals on anvils. I operate a Power Tool repair shop, and offer welding and machining services. I have over the years done some blacksmithing, and I supply abrasives and machinery to a lot of the local blacksmiths, including the college blacksmith program. I am in the process of starting to build a new shop and will have more room, so I would like to increase the size of my smithy area. As such I have increased my efforts to find an anvil and at this time I believe I am just going to order in a new one. I did the same to get a milling machine, searched for years for a used machine, finally just ordered in a new 10x50 vertical knee mill. Thanks all for the word of encouragement. Walter -

Double Horn vs Square Tail Anvils

Starlight Tools replied to Starlight Tools's topic in Anvils, Swage Blocks, and Mandrels

That has been considered, it is in the ocean right at the mouth of a river, and that was 45 years ago. Not sure what condition it would be in and how deeply buried in silt. Currently have a few sections of rail road track that are making do for when I need an anvil so finding one has not been an urgent matter, just trying to educate myself on the different styles of them and their uses. Both of the ones I am currently looking at are double horned and in the 275 lbs range. So wanted to make sure that I would not kick myself afterwards if I went double horned instead of square heeled. Walter -

Double Horn vs Square Tail Anvils

Starlight Tools replied to Starlight Tools's topic in Anvils, Swage Blocks, and Mandrels

Thanks guys, my only real anvil right now is a record anvil that is about 4-3/4 inches long and really more of a paper weight. I remember that in 1973, we were getting ready to move and my dad decided to try a flotation test on the anvil that we had rather than move it with us. Unfortunately, it did not float and I have wished ever since that he had not done that, but I was only a young pup then. Ever since I have kept my eyes open for a used anvil, but one has never come up. I have a few leads now and want to make sure I will get something that will be usable as I doubt I will get another opportunity to get one. Then again once I actually do get an anvil, maybe it will attract its friends and I will be able to get it company. Meanwhile I will keep doing research on the different styles of anvils, so any other comments gladly accepted. -

Hi, I am new to this site, I am a welder, millwright, machinist by trade and I a trying to determine the advantages or disadvantages of the two major styles of anvils, the two horn or the square tail. Been pounding for years on a section of RR track, but I am hoping to move up to a real anvil and trying to determine which style I should be looking for. Thanks Walter