-

Posts

970 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Donal Harris

-

Wrought Iron Hatchaxe Thing

Donal Harris replied to Donal Harris's topic in Axes, Hatchets, Hawks, Choppers, etc

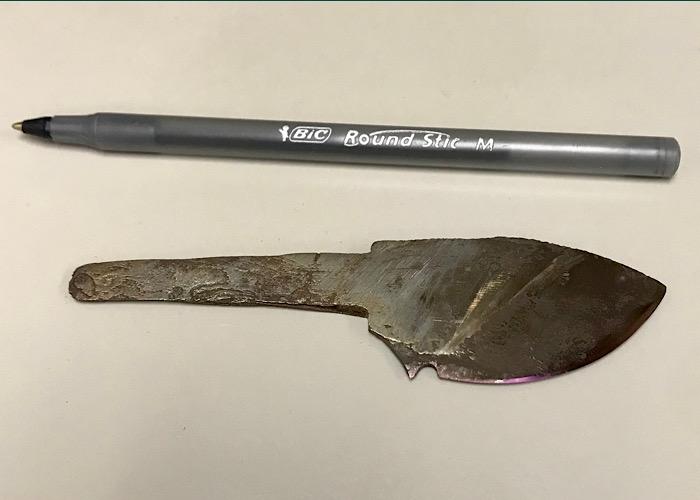

This piece is large enough I may be able to get this hatchaxe thing and a much smaller hatchet out of it, but I am not hopeful. When trying to make hammers out of it, I found myself losing at least half of the initial mass of wrought iron to scale. -

Jennifer called hers a hatchaxe, so I suppose I will too. I am shooting for something between a hatchet and a boy’s axe with a finished head weight of maybe 2 lbs and a handle about 24”. The wrought iron I purchased a couple of years ago from a guy in Petersburg, Virginia who was restoring an old building there. The back of the building had wrought iron bars over the windows. Most of what I bought was that, but there were a couple of larger pieces such as this one which was from a large hinge. The iron was produced in Richmond at the Tredegar Iron Works, which was the largest iron works in the South at the time. Knowing the history is cool, but also a little worrisome. Skilled labor became hard to find and the work force was supplemented with slave labor. Odds are probably good that all of the wrought iron I purchased was produced in large part by slaves. I am not sure how I feel about that. I am not selling anything I make using it, so I am exploiting no one, but someone in the past did. (It is not my intention to start a conversation about slavery, Lost Cause myths, or any such, and mods should feel free to snip it out if they find it necessary.) The piece as it is weighs 3.74 lbs. I was worried about cracking when I bent the wrought iron to form the eye, but I was able to get the hinge almost straightened without any cracking or splitting. It took me almost an hour to get the hinge to this point. I probably could have done this in less time, but it cools very quickly. I get maybe 7 or 8 strikes before I have to reheat it. Most of the work to open it was done by driving it onto the horn of my anvil. Once it was quite a bit open, I work it on the tail and side of my anvil. I will finish straightening it out and working it down to size later in the week. I am not sure yet what I will use for the bit. Probably leaf spring, but maybe a rail anchor. None of the files I have are wide enough. I won’t really know what I will use until I get to that point.

-

Hatchax build Steeled wrought iron

Donal Harris replied to jlpservicesinc's topic in Axes, Hatchets, Hawks, Choppers, etc

I am going to give it a go with this piece. It is 3.75 lbs as it is now. Almost enough to make two hatchets, but I expect I will lose almost half its current mass to scale. Bending it in half is the most worrisome step for me. -

What did you do in the shop today?

Donal Harris replied to Mark Ling's topic in Blacksmithing, General Discussion

Not much of a demand for ashtrays here in the Land of Round Doorknobs and Parking Lots. Heck, you can’t even smoke in many bars these days. -

What's your latest blade look like? Post em and let us see.

Donal Harris replied to HondoWalker's topic in Knife Making

Do you make your own micarta, Haywood? Oh, I knew what you meant, Frosty. I was just kidding. Although what I said about a novice being able to put out work way beyond their skill level for short periods is true to a degree. I remember when I was just barely breaking 100 for a round of golf, I shot a 2 under par 70 one magical day. It was the most amazing round. Every shot was flush and exactly as they were in my head. The very next day I failed to break 100. One of my worries about blacksmithing and bladesmithing is it may turn out for me to be the same as golf and guitars. With those I have quite a bit of knowledge about how to do it, but no real natural aptitude for either. I leveled out at a 10 to 12 handicap with golf. With guitar, if equated to golf, maybe a 30 handicap (bloody awful). -

What's your latest blade look like? Post em and let us see.

Donal Harris replied to HondoWalker's topic in Knife Making

True, but would it be a representative sample? It is possible for a noob like me to spit out 60 knives in a row of the same quality as the best Loveless ever produced. The odds of such happening are probably greater than they would be of me winning at Powerball, which Google says is about 1 in 293 million. Even greater when you factor in my never buying a ticket, but the chance of me producing 60 knives in a row of quality rivaling his is still a non zero number. -

What's your latest blade look like? Post em and let us see.

Donal Harris replied to HondoWalker's topic in Knife Making

I have about a 4 foot section of one of the thicker branches in the garage, plus a 6 inch piece I plan to use on a camp knife sometime, and the root balls from 3. I didn’t store them inside though, so much of each ball is riddled with fungus. I had them on a tarp behind the guest house. I thought that would be enough to keep them from rotting, but that was obviously wrong. I suppose I could cut them up and stabilize them. I’ve never cared much for spalted wood scales though. Guitars, yes. Knives, not so much. A set would be a problem. Catching lightning in a bottle once isn’t much of a feat. 4 - 6 times. Not so easy I expect. -

-

Where can I see how the holder is made for these? They are angle iron.

-

What's your latest blade look like? Post em and let us see.

Donal Harris replied to HondoWalker's topic in Knife Making

Steak knife. File sandwiched between wrought iron. Lost most of the wrought iron. Blade sharpens and will cut. Scales are from a dead bush from my yard I cut up and stored in my garage for about three years. Slight crack to one scale when setting the rivets. Hit it just one time too many. Maybe not bad for a first knife. -

Fire pot dimensions for coal forge

Donal Harris replied to Donal Harris's topic in Solid Fuel Forges

I don’t really have it lined with fire clay. More what I would call, “fire dirt”. I would have to drive out of town to find clay, and wanting to see how well the shallower pot worked, I just busted up a small scoop of dirt and packed it in the holes. But yes, it did spit out quite a lot of sparks when I used it after the last rain. The shallower pot is much better. In a few weeks I will take it back to my dad’s place and patch the top with pieces of scrap. -

What did you do in the shop today?

Donal Harris replied to Mark Ling's topic in Blacksmithing, General Discussion

Nice cone mandrel and flatter, guys. Technically my wife’s kitchen before work, but I tempered my scrap knife project this morning before work. 400 degrees F for an hour. I will do another hour the next time I am alone in the house for an extended period. She believes her oven is not a shop tool. The area where the bolsters will go are still not flat. Still working on that. Without a disc sander it is tough. I need to make a clamp for my vise to hold blades in place for filing. I didn’t do all that well with keeping the file in the middle of the WI sandwich, but other than that I am not unhappy with it. It sharpened and will cut. My plan is to make a sheath for it and use it as for EDC. Being short, it should be less spooky for people when I whip it out. -

Fire pot dimensions for coal forge

Donal Harris replied to Donal Harris's topic in Solid Fuel Forges

My forge stays outside in the weather. The pot is pretty thick, almost half an inch, so it would take quite some time for moisture under the clay to rust through. Still I would like for “some time” to be as long as possible. -

Fire pot dimensions for coal forge

Donal Harris replied to Donal Harris's topic in Solid Fuel Forges

Short of welding strips of steel to close off that big gap between the inner and outer pots, how can I keep water from pooling between them? I assume just clay will not do that? -

Fire pot dimensions for coal forge

Donal Harris replied to Donal Harris's topic in Solid Fuel Forges

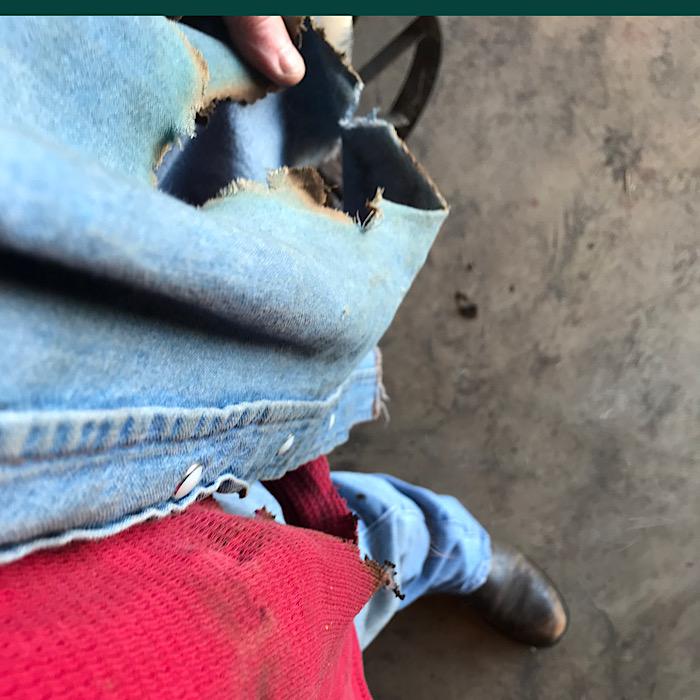

Well this one about got yanked off. I slapped and slapped. It just kept on burning. Tragic thing is I have a leather apron. I custom made it myself. But it is too tight to wear with more than a t-shirt on. I need to adjust both the waist and leg straps. My belly has grown to be huge over the past three years. -

What did you do in the shop today?

Donal Harris replied to Mark Ling's topic in Blacksmithing, General Discussion

After having bent over to pick the head of my flatter off the ground for what seems like a thousand times, I am about ready to drive in a wooded wedge. Shock be darned. -

Fire pot dimensions for coal forge

Donal Harris replied to Donal Harris's topic in Solid Fuel Forges

I still need to add clay, but I now have a shallower fire pot. I had planned to chop the bottom off and just reinsert it from the top, but that left it too deep still. I wanted 3.5”. So I welded strips of steel around the bottom and snugged the bottom of the pot to that. It is ugly as heck, but I don’t get points for that, so I am fine with ugly. What I am not fine with is losing my two favorite shirts in the process. I had the pot laying on its side on a welding table while cutting it. The shape of the pot was funneling all the heat and fire to the tails of my shirts. During the second cut I thought I smelled something burning. A few seconds later, I no longer thought something was burning. I knew something was burning: me. Luckily my skin didn’t get burned. -

What did you do in the shop today?

Donal Harris replied to Mark Ling's topic in Blacksmithing, General Discussion

It is healing slowly. I will have to take care to keep it from getting infected for quite a while I think. Of all my power tools, I fear my table saw the most. Good thing I guess. If I weren’t so cautious with it, I probably wouldn’t have taken the time to adjust the blade so it was just barely higher than the tree branch I was cutting into knife scales. After each pass I would raise or lower it for the next cut. As for missing thumbs, my mom lost one of hers to a lawn mower as a kid. My father-in-law lost his in what is probably the most painful way to lose one. He was cutting holes in 16 gauge steel. I forget what the machine is called. You step on the pedal and the die comes down and punches a hole in the steel. So essentially his thumb was smashed off. My dad, being the funny guy he is, cut the piece of steel so it would fit into 5x7 frame and wrote “The last thing my thumb ever touched” and gave it to my father-in-law to hang in his office. I just drop them in acetone for a day or two. They always break when I try hitting them with a hammer. -

What did you do in the shop today?

Donal Harris replied to Mark Ling's topic in Blacksmithing, General Discussion

Learned yesterday evening to keep my digits well away from the spinning blade on my table saw. My initial thought (well the one immediately after “Do I still have a thumb?” was “jeez that blade is sharp! I didn’t even feel my thumb move!” So, no hammer time for me today. This is my pot. It is too deep. I considered building it up with clay, but decided against it. It is 1/2” plate. If I cut it all around at the level of the chalk line, how close to my desired 3” - 3.5” do you guess I might get. I am thinking I could drop the bottom down into the top and it wouldn’t be as deep as it is now. -

What did you do in the shop today?

Donal Harris replied to Mark Ling's topic in Blacksmithing, General Discussion

Good repurpose of an unused hammer, John? It was back a page or to. Good idea, Frazer. If you don’t have what you need to make something you want, just use the tools at hand to make what you need. Basically finished my very first knife. I didn’t set out to make one, a personal steak knife, but that is what it is. I had a narrow file and WI. Put them forge welded them together into the shape the material seemed to want to be. Did three normalization cycles. Ground the bevels, ground the area around the bolsters flat and riveted them to the blade after shaping them. The hardened and que chef in re-warmed oil. It was at this point I realized I had made a mistake. I should have tempered the blade prior to attaching the bolsters. Put it in the wife’s oven while she was at work to temper at 450 for 15 minutes. Etched blade in muriatic acid for 12 hours. A bit long. It ate a bit more of the WI off than intended. But still OK. Cut the scales out of a bois d’arc log I have had drying for two or three years. Attached one scale and drilled the pin holes. Attached the other scale and drilled those pin holes. Rough shaped the handle using a 1 x 30 grinder. Glued the pins and fitted them though the holes and peens them. Finished grinding and the. Sanding with progressively finer grits. Did a bit to add secondary bevels. Soaked blade in instant coffee for an hour to darken the low areas of the steel. Buffed with very fine steel wool. Soaked the scales in BLO and placed on the fence in the sun to dry and soak up the UV rays so the bois d’arc would darken some. I want it a rich brown color. Tomorrow I will repeat with the other side facing the sun. we will see how it turns out. The first photo is me trying to decide if would from an old shrub would be better. Decided to stick with the bois d’arc. The second pic is the knife prior to linseed and coffee stain. The rest are the knife basically finished. Balance seems to be decent. Lots of mistakes with this first knife though. -

What did you do in the shop today?

Donal Harris replied to Mark Ling's topic in Blacksmithing, General Discussion

Likely the problem. Didn’t degrease it first. -

What did you do in the shop today?

Donal Harris replied to Mark Ling's topic in Blacksmithing, General Discussion

Sorry to hear that about your mom, SHC. Haven’t done much at the forge the past few days. Just doing little piddly things to a knife I am making. Got the bolsters pinned and cleaned up. Decided to add some copper and brass strips between the bolster and scales. Am now thinking I might should skip them and just go with scales. I cannot get the J-B Weld to hold. Tried both Sunday and Monday. The J-B Weld is failing but it isn’t due to temp. Unlike most epoxies, J-B Weld is stable up to 550 degrees F. Plus I was cooling it in water the minute it seemed warm to the touch when grinding. Rough the surfaces up more and perhaps drill a few holes for the J-B Weld to flow through between each piece? -

What did you do in the shop today?

Donal Harris replied to Mark Ling's topic in Blacksmithing, General Discussion

That walking stick was the sort of thing I was going for a couple of months ago, except I was shooting for the head being shaped like the Thrush Muffler logo. Screwed it up when I tried drifting the eye. I was working it too cold and split the side. I need to try again. It amazes me when people actually know how their line came to be in the US. We know nothing about ours. All we know is they came down from either Kentucky or Tennessee to NE Texas and the SE part of Oklahoma around 1863. That was my Dad’s side. On my Mom’s side we only know they settled in the IT near Ft Smith. As for yesterday, I started attaching the bolsters on a knife. How can I get a better fit? I tried using a file to get the surfaces of the blade and bolsters true. Didn’t work. Then tried sandpaper on a block. Didn’t work. Then I tried my beat up HF 1x30 grinder. Better, but I still couldn’t get them totally flat. I was using a magnet to hold them to the belt, but I just could not get the edges to stay flat. I found myself just chasing after something I could quite get. Maybe try on a better grinder next time? I believe I can make the gap a little less noticeable with JB Weld. Just now while typing this it occurred to me I forgot to temper the blade. Any way I can do that now without breaking down the JB Weld I used to attach the bolsters to the blade? I tapered the holes for the pins, so they should hold even without the epoxy. -

What did you do in the shop today?

Donal Harris replied to Mark Ling's topic in Blacksmithing, General Discussion

Did a bit more forging and grinding on the small knife. Going to HT and grind the bevels tomorrow. Still haven’t decided if I want a hole in the blade. I will also need to forge weld a bit of extra WI to the handle to build it up. I will be in Indianapolis May 13 - 18. Is there anyone near there whose forge I could visit? -

What did you do in the shop today?

Donal Harris replied to Mark Ling's topic in Blacksmithing, General Discussion

Bits of WI. Bits of an old file. I am calling it: vilains petits morceaux friables Perhaps a good vinegar bath and a nice scrub with the grinder will improve her looks and overall disposition. Dropped the bloody thing in the snow three times while forge welding it.