-

Posts

296 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Cannon Cocker

-

-

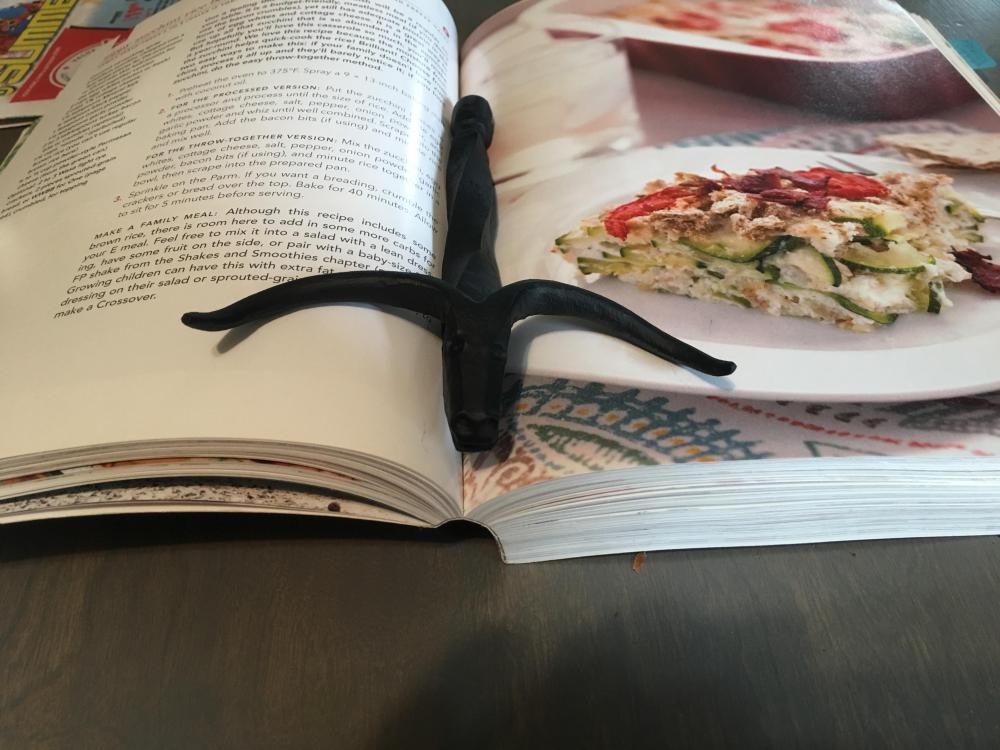

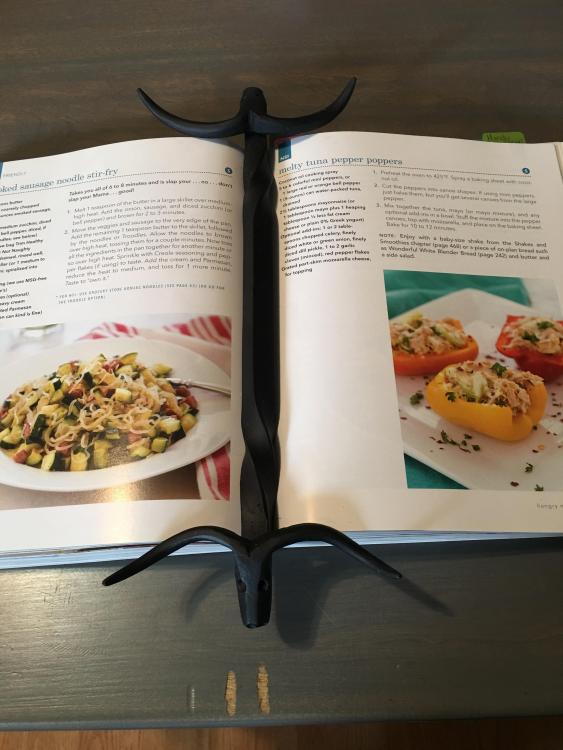

I got an order for 6 hoof picks the other day. So I made one tonight to try out one of my ideas. It turned out okay and I learned a few things that I'll do different. I have a few more complicated designs in my mind that I'll be trying out in a couple of days as well.

This one has a bottle opener on it as well.

This one has a bottle opener on it as well.

Chaos approved but asked me to forgo testing it out on him.

-

I don't think there is actually such thing as a "big enough" shop!

-

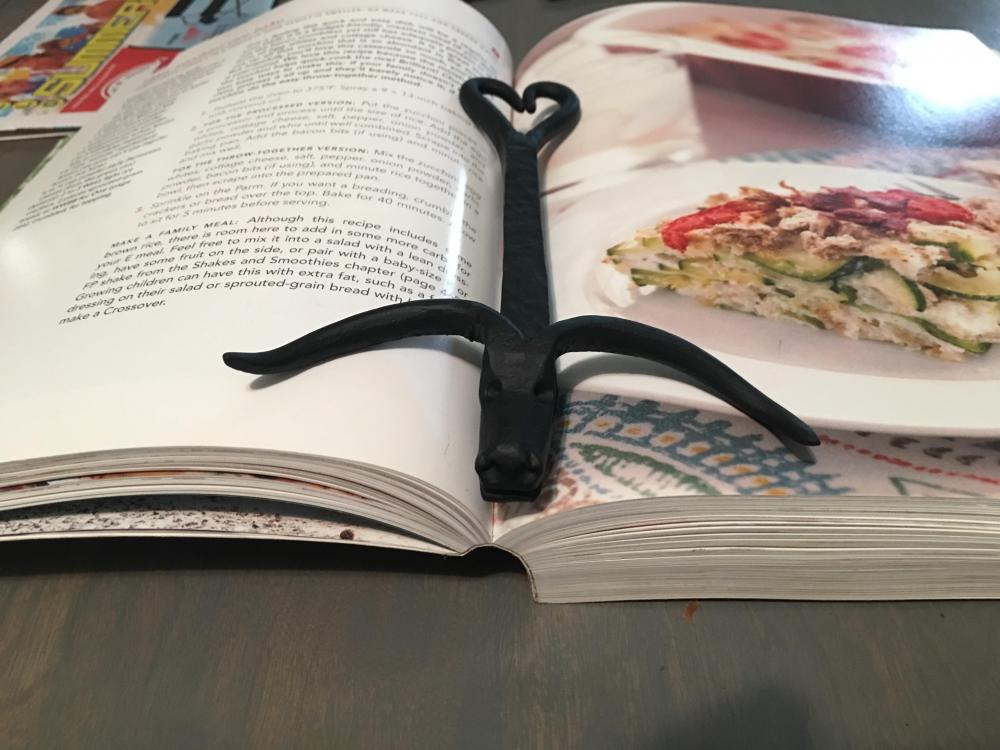

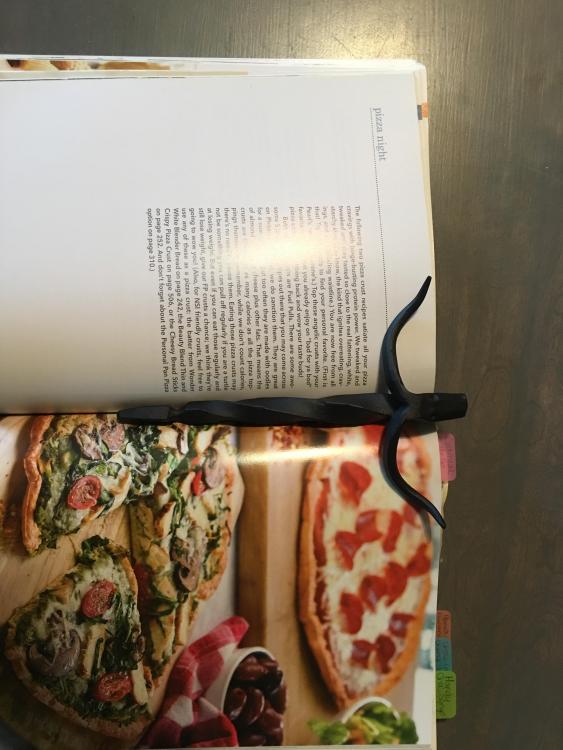

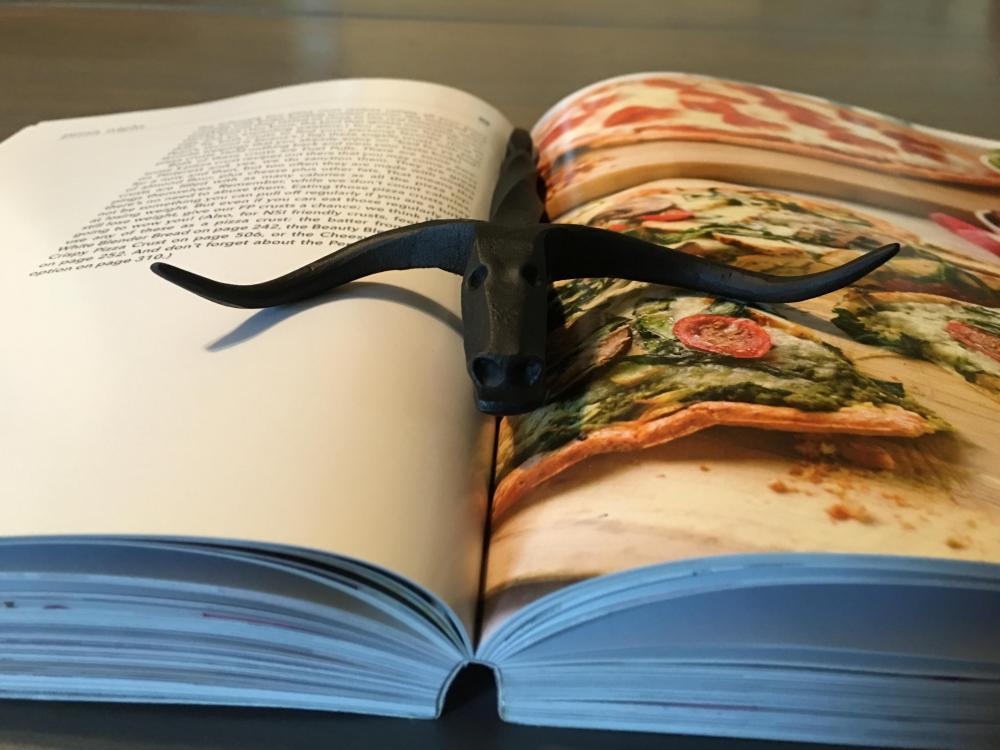

I just realized I posted my last days work in the "it followed me home" page. Sorry about that! It was once again to wet in the forest to haul logs so I fired up the forge. I made a couple more page holders and a Nordic belt buckle (still need to make the belt) hopefully I'll sell this stuff at a decent price to help pay the bills!

-

-

It's been a wet spring here in South Dakota too. We've had a record amount of precip. It makes making a living in a log truck a little difficult. But on the plus side I've had more time in the "smithy" lately!!

-

671 jungle that is a steering shaft off of a truck. Probably a semi.

-

Das, I thought about putting a ball on the other end but I thought that the spring steel might want to be heat treated so I decided to make it in a way that was removable. So far I don't think it's going to be an issue but you never know. I did however have to take it apart already. The position the handle was in put the rivet end pointing directly up when clamped down on 1/2" material, which is the most common thing I put in the vice. So I cut the rivet off, inserted the handle 180 and re riveted it.

IFC thanks for the heads up. I've never been bitten by a vice handle. But a couple of wraps of leather can be a good insurance policy to keep my record going!

I guess never being bitten by the handle is a bit of a lie. In the shop at the Mill we have a big machinists vice and when not under pressure the handle swings very nicely. I unclamped a piece one day and let go of the handle. I was standing to the side of the vice so when the handle swung around it hit me right between the "uprights". I think I'd take a blood blister over that!

-

-

-

I love him too. He's not a whole lot of chaos most of the time. I named him after one of my heros. General Mattis' call sign was Chaos. Is follow that man anywhere!

-

Chaos is pure bred golden retriever. Also excellent at making friends!

-

I cut the stump down for my second Anvil. And then I had to try it out. It has WAY more rebound than the big chunk of mild steel I've been using for an Anvil! I don't have a ball bearing to measure it with, but when I hold the hammer about 6 inches above the surface and let it fall it bounces almost all the way back to is starting point. So I had to try it out. I started forging a fork.

-

No he doesn't bring home any other dogs. But he likes to make friends with every one and any thing, so I'm pretty sure he'd bring them home if it was an option!

-

-

That bushing is probably "oil lite". If that's the case it means it is brass infused with a lubricant that releases through wear. (at least that's how I understand it from reading McMaster Carr). If you try doing anything with that let us know how it turns out. I have a nearly endless supply of that from the mill I work at.

-

Check with your local propane dealer and get a used 100# tank. Then take that to a welding supply store that does exchange programs with the bottles. I get 100# of propane for just over 60 bucks. That's about 1/3 of the price I was paying with the grill sized bottles...

-

Sorry if my question seemed rude. It looked to me like a round taper at the top in your first picture.

A uniform twist on a taper is a hard thing to do. Keep working on it and you'll be knocking out cool hooks in no time!

-

How are you planning on attaching that hook to the wall?

-

12 hours ago, pnut said:

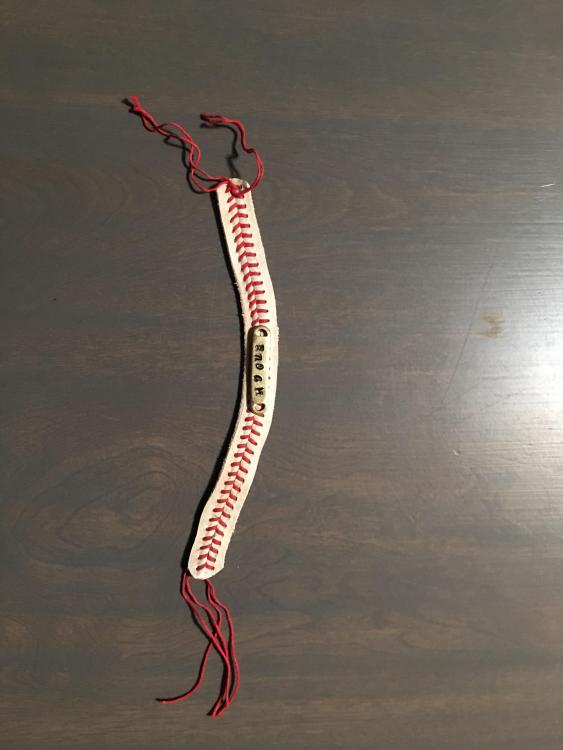

Cannoncocker that's a pretty simple stitch to learn If your wife would rather stitch white leather instead of skinning baseballs.

That's a decent idea pnut. However, these bracelets are for the moms on our son's baseball team. They are made from old balls the team has used so there is a connection to them. She also feels that even if she was selling them the fact that they used to be baseballs is important.

-

I like your idea cedar Crest! I do get the kids out in the smithy with me quite a bit. Maybe I'll let her be the striker to flatten it out too.

-

-

-

I finished the last two anchors for the trampoline.

Then I made a little Anvil for my wife. She is making bracelets out of baseballs with brass name plates on them. The plates have a curve to them that needs to be held while she stamps the letters in them. Long story short I got to make a special punch and then stamped the shape into a piece of 1/4 X 1 1/4.

-

Good job making another addict!!!!!!!!!

What did you do in the shop today?

in Blacksmithing, General Discussion

Posted

Not yet. I've used many hoof pics in my life, I'm sure that this will work fine, but I've got a friend who's a ranch hand that I'm gonna give this one to to see how he likes it.