-

Posts

67 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Gustav

-

JHCC, it's the third largest province in Sweden (out of 25) at 29 330 km^2 (~11324 mi^2) but compared to most states in the US it's quite small, yes. Everything is bigger in the US, right? And Frosty, thanks for letting me know!

-

George N.M. Wow, that's interesting. I also have ancestors that immigrated (also from Småland) around the time your grandfather did. I might have heard about a Månsson sometime, but Småland is very big. It's a big chunk of southern Sweden. Buzzkill Okay, it might be the sharpening angle. I thought "oh this is a chopper so it must have a really high angle" but I might have gone too far. I will keep that in mind!

-

Buzzkill - Ok, what angle did you aim for?

-

Buzzkill - It stays sharp, but that's good to know. I chopped a lot of wood when trying to get it in place for the picture and it didn't lose any sharpness. I just couldn't bring it to shaving when I sharpened it in the first place.

-

Thomas Powers - Forgot about that. 80CrV2 quenched in canola oil and tempered at 200°C 1h x 2

-

Hey guys! This is my first "weapon", a 35 cm long bowie. It's also the biggest knife I've made so far. The blade has a warp and the "brute de forge" might have been too much. I could probably also have ground and polished the guard and pommel a bit. They were cast in a metal I don't know the name of in English, but it's 85% Cu, 5% Sn, 5% Zn, 5% Pb. It also doesn't really shave, which is a bit lame. I went from 300-600-1200 on diamond stones and finished on a strop with green polishing paste. Go finer? Make sure you have a small angle? What do you think?

-

Thanks guys! You might have noticed it too, but my main problems are 1. The brass spacers between the ziricote and bocote don't line up on each side of the tang. And 2. The brass could've been finished better Regarding the "stubbyness"; no offence taken!

-

I've been blacksmithing for almost 3 years, the last of which has mostly been bladesmithing and during this time I always had in mind that I was going to give my dad a knife when he turns 50. It's my first knife I've given away, my other knives are mostly for display (to remember the mistakes each one had) except for my first kitchen knife, which I use every time I cook. They've all been pretty simple. One full-tang and the rest hidden-tang. Turns out, my dad liked the full-tang knife the most, so it had to be a full-tang. So here it is; 80CrV2 finished to 600 grit, brass, ziricote, bocote and mosaik pins, oiled with boiled linseed oil. By far the best looking knife I've ever made, with minimal mistakes (compared to my other knives). Just a bit scared of the unstabilized wood I used. Last full-tang knife I made had wood that shrunk an insane amound, not just so you can feel the edge and the pins, but actually see how far everything sticks out. Fingers crossed! What do you think?

-

Hello! I've had a couple of cheap whetstones (120/400 and one 1000/3000) with a leather strop (with green compound) for quite some time now and I started to get tired of them curving and creating one huge muddy mess when sharpening many knives. It works, but it's a pain xxxxxxxx sometimes. So, I bought a 300/600 grit diamond sharpening stone from Dianova, but it feels like it wont be enough. When you have a newly made knife and want to create the secondary bevel from "no bevel at all", do you think the 300 grit side on that diamond stone will suffice, or will it be too fine of a grit? Maybe getting a extra-extra coarse diamond stone like 120 will do? Also, will the 600 grit be fine enough to go straight to the strop? I'm looking to get shaving sharp edges. Other than that, I'm not interested in "Oh this was sharpened on a 30 000 grit stone wohooo". Maybe getting a 1200 grit diamond stone to use between 600 and the strop? So: 1. Will a 300 grit side on a diamond stone be coarse enough to effectively create edges on newly made knives? If not, what grit will be the most suitable before 300? 2. Will a 600 grit side on a diamond stone be fine enough to go directly to a strop to get shaving sharp edges? If not, what grit-steps are required after 600 and before stropping? Since I've gone up to 3000 on my whetstones and gotten shaving sharpness after stropping, I know that's possible. But I'm not sure what the grits are for diamond stones. People seem to go to higher grits on whetstones and not quite so high on diamond stones, but I'm unsure. The reason I'm asking this and not just testing is because I currently don't have any knives to try it on, I'm away for some time. Commercial link removed per TOS Thanks in advance!

-

Got really surprised today at how fast things went today, the forge is now completed. It's very ugly and very crude looking, the blower is attached with ducttape and the welds look like bird poop . Now I'll just have to get used to regulating the airflow, the hairblower I had on my old forge was really simple to use (OFF/half blast/full blast) and I only ever had it on full blast whilst forging. On this forge I actually use the ashdump and the clinker breaker to regulate the airflow. It enables me to fine tune, which is new to me. VID_20190804_173944.mp4

-

Turns out you could adjust the airflow quite effectively with the ashdump and clinkerbreaker, so I just permanentley have the blower at full blast. Problem solved!

-

Hello. The new blower I have has an internal gate to adjust the airflow, but it is affected by the air as it pushes through. The air basically opens the gate no matter how I adjust the airflow. This is probably because the hinge of the gate is extremely loose. When the lever is pushed to the left on the pictures, it's 100% open and when it's to the right it's 0%. How can I make sure the lever stays where it is regardless of the airflow? The forge I'm building is in this thread. // Gustav VID_20190804_134719.mp4

-

Progress! The firepot isn't fastened down, it is a tiny bit loose if you try to move it since I just placed it in a rectangular hole. That's fine, right? The rectangular pipe you see welded "behind" the firepot on the frame was of some weird steel that didn't want to weld. I filed both sides down to fresh metal but it just wouldn't hold. I had it welded all the way but when I removed the clamps it just snapped outwards and all the welds disconnected . Maybe take some 20x5 mm mild steel instead? I'll figure something out.

-

Adding wheels in some way is a good tip, thank you. However, I need to be able to lift and carry it by myself. I won't just be moving it across the floor, but also in and out of a huge oven to benefit from its chimney. I managed to cut the table today and I ended up going for 31x22". I still had plenty of space for my firepot. 27" looked good when I drew the forge in CAD and would probably be the best performing, but when I visualized it infront of me while I were at the table, it seemed too big.

-

Just cover the sheetmetal with vinegar and wait? We actually have a sandblaster, but I didn't want to use it since I thought that sand would end up in hinges etc and mess up the firepot's mechanics. Is it safe?

-

Hello everyone My wheel rim forge I've had since the beginning had broken down, so I began building a new and better forge. I found a 800x1000 mm (31x39")metal frame with four 900 mm (35") legs in my backyard and welded on two 4 mm pieces of (super rusty) sheet metal to make the "table". I also found a firepot with inner dimensions 220x180x40 mm (8.6 x 7 x 1.5"). It also has a clinker breaker, which was nice. All that for $100! Well worth the 2 h drive! The new fan is a $60 forgeblower I found in a Facebook group. When I plugged it in today just to try it I got really surpriced about how quiet they are. I never noticed how loud hairblowers (my old blower) are compared to "real" forgeblowers! Here are some pictures: Now, onto my questions: 1: The table is too heavy right now, even just as it is without firepot etc. It needs to be portable and easily movable by one person, which it won't be if I continue attaching more equipment. I read on IFI that 30x30" or 24x24" is a good size, so, since it's 39" wide and 31" long, I'm thinking about cutting it in half and welding on just the legs on what's left to make it smaller. So that it becomes 31" wide and x" long. I'm thinking that x < 31", since I don't want a square table but how "short" do you think it should be? As long as the firepot fits, how short is too short? Space for my coke is obviously important, but portability is also very important so I don't want it "longer" than necessary. 2: What should I do about the rust on both the table and firepot? Is there any other easier way of getting rid of it except going at it with a wirebrush on an anglegrinder? Happy for all answers. // Gustav

-

Forgot to post the update. I filled the cavity with some mig welding and it got really ugly (the welds are ugly because the welder can't use gas) but it works better now. In short, if you have to fill in material with a welder, just forge a new piece instead. It might make it usable, but it gets really ugly.

-

Oh xxxxx I received the steel yesterday and tried forgewelding today. Didn't go very well... I used borax and it first took 6 heats to get the two pieces to stick, but when I welded the other side it broke and fell off. After that, I tried it again for about 20 heats and stopped only because my forge broke down. It wasn't because I tried forgewelding, but simply because it has been seeing its last days for quite a while. It's an ugly wheel rim forge driven by a hairblower, and the welds on one leg broke and the hairblower stopped working lol. I put that little guy to work, for sure. Back to the forgewelding: I had troubles reaching welding temperatures and putting the two pieces in good positions inside the forge where they got heated up as much as possible while at the same time being accessible to me when I want to take them out. This probably made them not reach welding temps. It might be because the coke I have are huge pieces (golfball to baseball size) which makes it very annoying to put stuff in and out of the forge. But do you think it has an effect on temperature? Will smaller pieces of blacksmithing coke get hotter with a non industrial blower like my hairblower?

-

Hello A few months back I made my first rubiks twist bottleopener and was quite pleased with it, but I thought the lip was too thin. It survived me testing it but after my graduation this spring we had 20+ guests and it got used quite a lot so it bent backwards and cannot open any more bottles. How do I solve this? Heating it up and bending it back again will just be a temporary solution, but what if you tac weld the back of it so you add some material? Maybe just fold the tip and push the ring closer? If it was one of my normal bottleopeners I'd just make a new one, but since this is my first rubiks twist it would be nice to fix it.

-

Using an existing chimney with a super sucker

Gustav replied to Gustav's topic in Chimneys, Hoods, and Stacks

I thought the air from the fan would go up the chimney and pull the air in the super sucker with it, or atleast assist -

Using an existing chimney with a super sucker

Gustav replied to Gustav's topic in Chimneys, Hoods, and Stacks

Forgot about something that can help quite a lot: There is a little tunnel right outside the ovens double doors that goes under the doors and up into the bottom of the oven. This is where a large fan (probably around 30 cm / 1' in diameter) is used to blow oxygen into the coke inside the oven when melting metals. It could prove useful since it blows air (don't know exactly how much) right up and with both doors closed, it could push quite a lot of air right up the chimney. -

Using an existing chimney with a super sucker

Gustav replied to Gustav's topic in Chimneys, Hoods, and Stacks

I was unsure about the placement of the connection, so I just placed it as all other super suckers. Good to know that it works on the side/back too! -

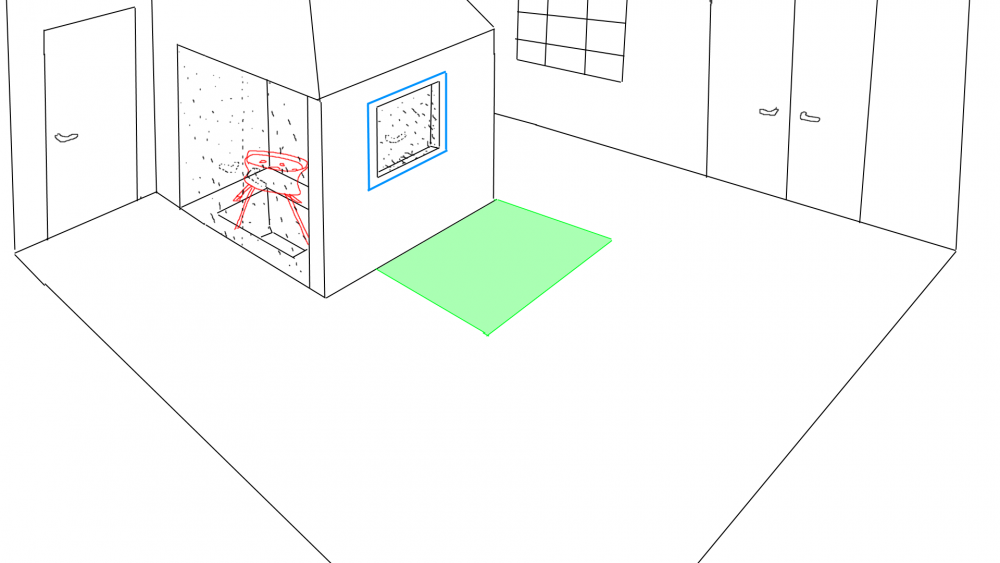

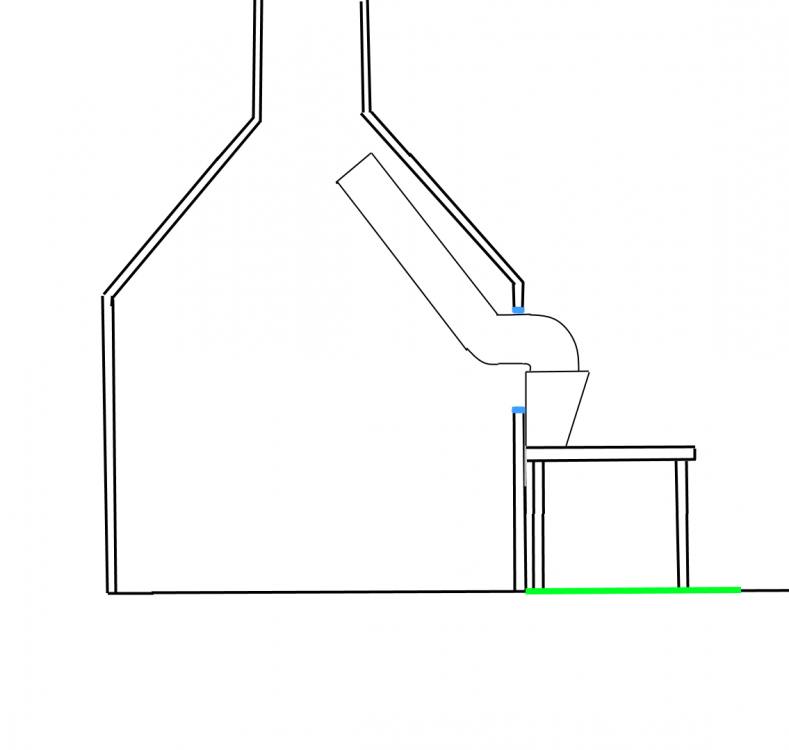

Hello. I've read a lot recently about the super sucker forge hood and I've got some plans, but I need to hear from you guys before I start messing around in our shop. But first, some context: I forge in a family owned foundry (building that focuses on casting is called that, right?) that my father works in from time to time. The picture illustrates one part of the building where the oven and chimney is located. The oven has a main opening with double doors and a smaller door (marked in blue) that's never used anymore. I drew the room in Paint.net since there's so much stuff laying around that's in the way... So: when I want to forge, I move my abomination of a forge (the red rim forge) from some other part of the building into the oven to use the existing chimney. This makes every forgingday into, as you can guess, quite a hassle. It's very time consuming and annoying to get going, not to mension the amount of steps I have to take between the forge and the anvil during the actual forging. Why? I don't want it to get in the way for my father who uses the oven when he melts and casts various metals from time to time. I'm actively looking for a "real" coal/coke forge since I'm tired of the one I have (it was the first I ever built and I've had it for 2+ years) and I've been doing some thinking: I can possibly move some stuff around and place a potential forge somewhere in the green area. This gives the forge easy access to the chimney from the blue window. BUT, here's the catch: the chimney obviously isn't just a 12 inch pipe/tube going directly from the "box". It's a chimney going into a bigger chimney. I don't have any measurements on me right now, but do you think something like in pic 2 will work? Does the tube have to go up further into the "real" chimney or is it enough just a bit into the oven? The doubledoors aren't 100% airtight. I felt in the beginning that this was very much "workshop planning" but still posted it here since it's almost just about forgehoods/chimneys. I also have some questions about the effectiveness of the supersuckers in general. It looks amazing in videos, but let's say I use coal: does it get overly dusty, smelly and dirty even though you use a fully functional supersucker? Do you still get black dust in your noses? I cannot use coal in my current "setup", only coke. Coal produces too much smoke and I inhale a lot of it when I reach for the forge. I know it's a long post, sorry. Sincerely, Gustav

-

Forgot about the upsetting before scarfing, thanks! I also understand what you mean by not tapering pic 3 all the way down. I've never forgewelded before but I'd like to learn, and I think this is good practice. I'll get back to you when the steel arrives and I have time to forge!

FotonochvideoklipppInstagram.png.d88a039511bb6bacefbffff6dd7f3fb4.png)