-

Posts

370 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by FlatLiner

-

-

Nice anvils JW513, I also would like a Holland church window, I really like his Swedish/South German pattern anvil. When I get enough spare change that's the one I'm getting.

-

-

Just picked up a 130 lb columbian anvil to go with my 125 lb soderfors both anvils are age unknown and I haven't been able to find serial numbers or years on them. The edges arn't as banged up on the columbian from cold horse shoes as the soderfors was. But you can tell it did do some cold shoeing. The Ring is as loud as the soderfors but a slightly different pitch. The ball bearing test using a 1 1/2" bearing has a return bounce of 85-90% whereas the soderfors has 90-95% return. All in all I am a happy camper. Two legendary anvils that can forge whatever I want on.

-

I'm Amazed again. Good job.

-

Amazing absolutely amazing.

-

When I saw them I remembered your anvils Thomas, that's why I grabbed them.

-

-

-

-

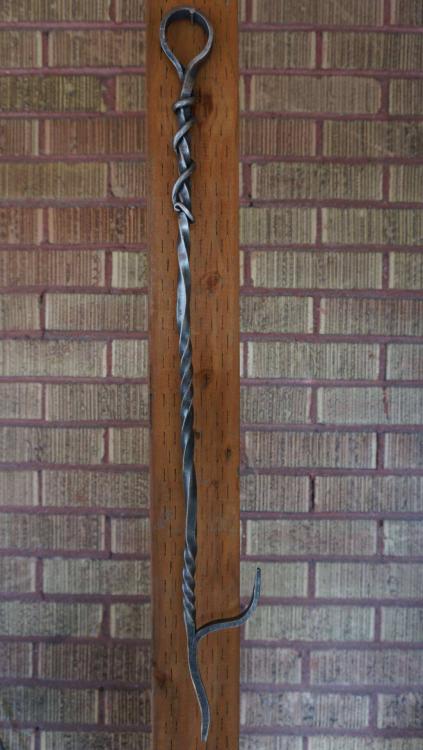

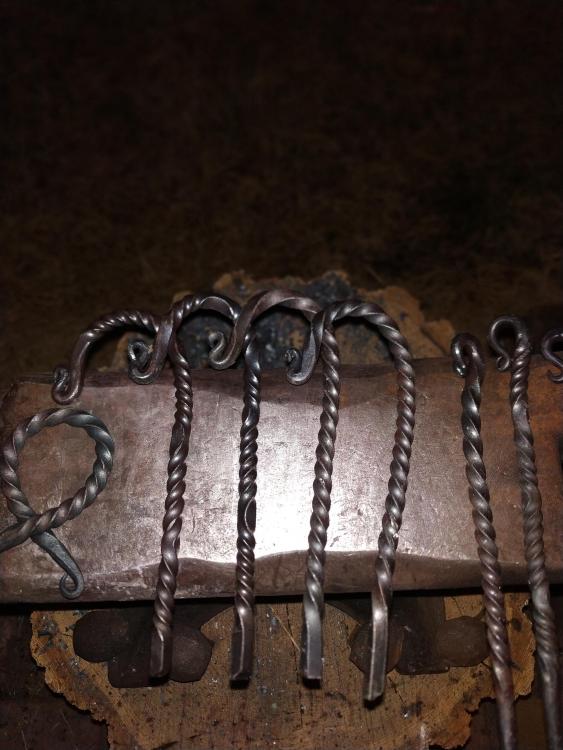

I was going to leave them as is just with wax and tie them up with red ribbon to off set the color.

-

-

Holland has a 230 lb sawyer anvil for $1050.

-

That's a good looking anvil. I wish I could find something similar down here in SLC, Utah.

-

Ahh another tux user. Good to see more people seeing the light.

-

That was an interesting hammer and sledge hammer they where using in the video you linked to Thomas. There's alot you can learn from these third world blacksmiths.

-

Here ya go aaamax

The pics don't do justice to how bad some of the edges where. After some pieces nearly cut me as they flew off when I was forging I knocked them down with a flap wheel. Now she has more curves then a south German style. I can find the right curve or radius for whatever I am doing. I know many people would fault me for it but for safety sake and the fact I couldn't find a decent edge on on the sweet spot(it looked like a saw blade on both sides down the whole face of the anvil).

Here she is before and after.

Here she is before and after.

-

Nice burner Jungle.

-

I would love to find an unbeatenup soderfors Frosty but I had to settle for a soderfors mangled by years of horseshoeing in the wilds of Wyoming. I couldn't pass up a soderfors for a good price :-)

-

That would be a sweet anvil to go along side my beat up soderfors. I wonder how expensive the shipping from Sweden to the USA would be?

-

I watched it on YouTube and gave you a thumbs up. The church window anvil is one of my favorite anvils.

-

Most propane refilling stations have a "work shop" that you can buy the size of needle valve you need.

-

You can hit up Jymmie Hoffman. I built a blown burner off his design. It's dirt simple but works great. It consists of 3; 1 1/2 T's, 2; shorter 1 1/2 nipples, 1; 5" long 1 1/2 nipple with one side smashed down to an 1/8" opening, 1; 1 /2 plug, 1; 1 1/2 by 1/2 bushing, 1; 1/2 by 3/8 bushing, 1; 3/8 needle valve, 1; 3/8 quarter turn gas valve with the apropriate ntp connectors to attach to your propane tank. You will need a blower with some sort of gate valve also. Here is a pic of his burner design.

-

I really like seeing the anvils you build. Good luck with the heat treat.

-

Nice anvil. I love my Soderfors.

Columbian anvil question

in Anvils, Swage Blocks, and Mandrels

Posted

I picked up a columbian anvil recently and I am trying to figure out if it is of columbian manufacturer or if it is one of the swedish columbians. It is 130 lbs, no handling holes, the c inside the inverted triangle on the far side of the anvil if the horn is faced to the left. Now comes the interesting part for me. There is no M on the near side if the horn is faced to the left, and there is a C under the horn. It is covered in a thick layer of paint so I can't distinguish if there is a made in sweden stamp or serial numbers or anything else. Does anybody have a clue as to this anvil. I haven't found anything using my googlefu.