Peppie

Members-

Posts

228 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Peppie

-

Irondragon,, dooly noted. Probably 3' away from the forge. It would have to be a runaway propane fire to get to the O/ A tanks. By that time I would be in the front yard dailing 911.

-

TY Frosty, Dont need no stinking gutters.lol There is a back door on the forge. Dont have a need(yet) to pass long stock thru. But when I do... I can. New ribbon burner forge idea rolling around in my head. I will post up the idea soon to get some feed back. Kinda want to place the burner to the bottom right hand side ( pointing up) of a 16" diam tube. Resulting in to direct flame to the steel. Dave

-

JME they do make a nice swage. But if I can pay a bit more and have more of the profiles tha I will use.........

-

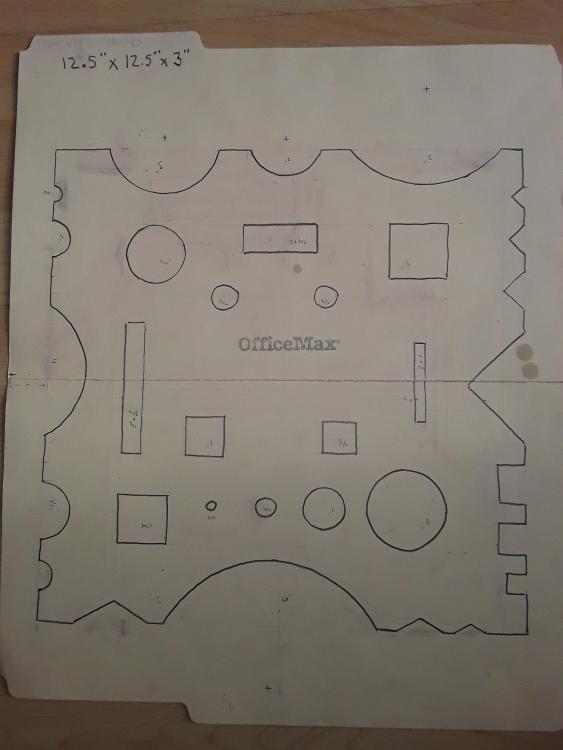

My buddy got back to me. I can have this water-jetted for a total of $375 with 1018 steel. Do I? Or dont I?

-

ThomasP yes The forge has a back door. It is closed off most of the time. There is also a heat sheild between the forge and the propane bottle. If I need to forge some thing long the heatsheild is removed and the bottle is also moved out of the way of the heat. Hojpoj yes they are alum. They were cut offs from a composite deck rail project I did years ago. There are holes drilled thru them to mount a screw on the inside of the 1" sq. Tube. Cant find a close up sorry. 4 elements. Lol the scrap pile is out of site.. out of my wife's mind. What you cant see, cant hurt you. Trust me there is a pile.

-

What did you do in the shop today?

Peppie replied to Mark Ling's topic in Blacksmithing, General Discussion

The top of the jaws are about 3/4" higher than the bench top. Havent found it to hinder any use " yet". I do need to be aware of its placement when I build jigs for it. I was told it is a German design. 5 3/4" jaws and weighs about 90- 100lbs. I still need to place a steel plate under the foot. -

Great advise Glen. I do need to add more outlets. I was thinking of running a multi- outlet extention cord around the inside top edge of the hut. That will keep the cords off the ground when tools are in use. And yes shelves and hooks are in the near future.

-

The S glasses will have a home on the plywood 1/2 wall above the bench soon. I live in a safe neigborhood. All is in the backyard behind locked gates.

-

Been putting this together for a little over a year. Looking for feed back on things that just are not right, or improvements that need , or should be made. I have tough skin, so let me have it.

-

What did you do in the shop today?

Peppie replied to Mark Ling's topic in Blacksmithing, General Discussion

Almost done.... lol ...it will never be done.... or will it? Added crushed rock to the forge hut today Took me a year to get to this point -

Great point George, I will be reworking some of the edge placements. Wouldnt a 120 degree "V" give me the equilateral ? I have the 120 but not the 60.

-

You are right I wont be machining it myself. I have a buddy who owes me a favor. I am hopeing the cost is no where near that.

-

What is an EDM? Have been weighing out cost, time, labor,and compramize shapes. I am in the research phase.

-

-

It will used on a very limited basis. Maybe a couple hours a month at best. This is a hobby for me. Cant justify big bucks for old cast one. It will only have 1/2 rounds on one edge. And a few different angles on the other edge. I have striking plate for the round and square holes that would be in the face side of a swage. Thanks for the reply

-

I have a source for 3" thick structual steel.I also have a source to mill it. Am I wasteing my time, money, and energy trying to fasion a simple swage tool out of it, if I have no means to heat treat it.? Peppie

-

TY the vise has a piece of angle welded under the base, that extends back intop the underside of the top. Hopeing it will hold up in time. If not I will add an angle brace down to the frame for a more rigid mount. Was trying to keep the top removeable. The Wilton will get light use. The leg vise on the other side of the forge will handle all the heavy work.

-

What did you do in the shop today?

Peppie replied to Mark Ling's topic in Blacksmithing, General Discussion

I thought about that... I will if I find that setup isnt holding up very well. I was trying to keep the top removeable from the base. Guess I could use bolts instead of welds. TY for the feed back -

What did you do in the shop today?

Peppie replied to Mark Ling's topic in Blacksmithing, General Discussion

Finished up my welding table, first one I build was a bust ( the top twisted ) Not a welder by any means, but I am getting better. 4' X 2' X 33" tall. This one wont twist, and way out last me. -

My last welding table was a total failure. The top was pieced together with material I had on hand. After it was all weded together.. the top looked like a twisted rollercoaster. This one has a 5/8 , plate top ( 2' X4'). Legs are 2 X 4 tube, with 4" channel for rails. Heavy little sucker! Approx 300lbs I made adjustable feet, and added a custom plate to the end to mount my Wilton.just needs a shelf, and a couple coats on paint on the stand.

-

Show me your Bottle Openers!

Peppie replied to Arbalist's topic in Blacksmithing, General Discussion

-

What did you do in the shop today?

Peppie replied to Mark Ling's topic in Blacksmithing, General Discussion

I have spent alot of time designing, and fabricating things to make thing for the forge as of late. Today I took the day off today to play. My 3rd opener. Still working on cleaning up the details on my work. Today was a win, even though it took me 2 hours to produce a 30 min project. -

The vise was missing the spring when I bought it. I bought a race car spring 85#, and cut it to fit. Seems a bit stiff, but none the less works for now. The lock collar you speak of? Not sure I understand how it works, or even if it does. I will check it out further. I was told the vise was a" pendigus" (sp) weighs about #90, with 5 3/4" jaws. I luv it. The table is a nice" workhorse" addition to the forge. I am sure it will out last my forgeing days.

-

Ty Beavers, My welding skills are improving along with my lack of needing to grind so much.lol I will install a bi-pass door rail at the face of the canopy opening so I can protect the table and vise from the weather. I like the idea of being able to slide a door panel ( metal sideing). Out of the way when I work at the table.

-

TY, Motomike, I have not seen one like that either...until I bought it. Lol Must weigh every bit of 90#