-

Posts

115 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by winterbear

-

-

If my buddy with the crane truck doesn't get back to me I'll start working my way thru my local farmer friends to see who may have a tractor with a loader bigger than my little 9n ford (it's max is under 1k) I have been clearing a spot and switching some wiring around in my panel so trying to not think about it just sitting there. If none of that works I am building a A frame this weekend even if it is just a timber frame I can lift the hammer and drive out from under it. Chris

-

Frosty, it's all tarped up on the trailer waiting to be unloaded. As soon as it is unwrapped I'll get more pictures up. And video of it running. Chris

-

Steve, thanks for posting. I had actually seen your thread when this hammer came up for sale and I was planning on PMing you about pictures. I see you have yours on timber over gravel, does it move or walk on you at all? Does anyone know if pounding out the profits book has any serial # info? I'll have to see if I can find a copy or see if someone can share what is in there related to the Modern hammer. Still waiting to unload its driving me nuts that I can't use it yet.

-

Vaughn should be running in a temp spot in the shop as soon as I can get it unloaded. It's got a 12ft pigtail to wire it up so I have a spot close enough to my panel to direct wire it into the breaker for now and I'll figure out a more elegant switch when it gets a permanent location. I don't think this model would get 10" of clearance there is no adjustment on the rear connecting arm like the larger model looks to have so the sliding pivot may be the only adjustment point. Now if my buddy with the crane truck 3 miles from my house would just get back to me. Chris

-

Or it could be a earlier version as mine has 1904 cast in the base. Chris

-

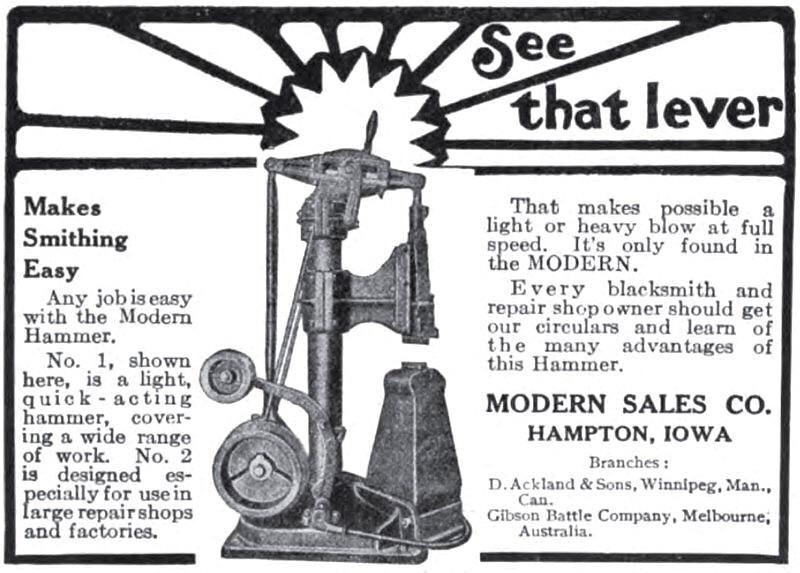

Awesome black frog. I hadn't found those ads yet. I wonder if the second ad you posed isn't the heavier #2 model referenced in the ad I posted. Chris

-

vaughn I'll have to check the distance between the dies. That is one question I had if it was set up correctly. I think you could adjust the height of the guide but not sure it would do much except maybe get some additional clearance. That is of course with standard dies maybe more being it like you said for specific jobs. I am betting most of the design around the central upright was 2fold ,smaller castings and it could be shipped easier and assembled on site. Here are some loading pics for fun , and you can see some details on the sliding pivot. I'm the one with a beard and in the black hat. And one of my daughters in the last shot inspecting the hammer after it was on the trailer. Chris

-

Thanks Frosty, yes the lever adjusts the pivot point. There are maybe 6 notches for adjustment and when I test drove it it was surprising the difference between settings. I will post some more detail pics over the next few days as I get it unloaded and in its temporary spot in the shop and some video running. Chris

-

-

So next steps are to get it unloaded and tucked into the shop on some oak timbers and run it a bit before I decide exactly where it will sit, and decide if it will need a larger foundation or not. If anyone has any info or insight on this hammer or general recommendations I would be all ears. Needless to say I am super excited. Chris

-

So I have joined the club! I am the proud new owner of a old power hammer. Saturday morning the adventure started before 4am and hitting the road before 4:30 for the 3 plus hour trip to NE Oregon for a shop sale advertised online. Mostly hit and miss engine stuff and a bit of blacksmithing equiptment. Got there early waited till opening at 8am headed straight for the hammer. Asked a ton of questions looked close at just about every part ran it a bit smashing a oak 2x4 easily. I made a offer and I got to mark it sold. So it should be a 50lb head weight , 3hp single phase motor , all mounted a a 1" piece of plate steel. Runs good clutch and break are great, dies are good for now, one old break welded long ago and looks to be holding fine. Interesting feature that changes the pivot to allow light the heavy blows while running.

-

Subok that is a pretty hammer! Chris

-

xxxx that does look clean , see why I wanted to ship it across country

glad to see it went to a enthusiastic owner. and holy cow what a deal on the anvils and vices were those at the county as well?

glad to see it went to a enthusiastic owner. and holy cow what a deal on the anvils and vices were those at the county as well?

Chris -

Larry stated it pretty well prices here bring a premium, his previous post exemplify this. And that is why I as a aspiring artist must look elsewhere for a "deal" or make my own. Now I would find it hard to believe if anyone found a potential deal of 25% or even 50% including shipping of the going rate on a coveted piece of equiptment that they funds permitting would pass it up no matter where it was, which is what prompted my OP :) Seattle with it's rich history of industry and shipping is not all of washingtion state, I live in the relative smithing and tool wasteland of eastern wa, even if I found a hammer in the seattle I-5 corridor it is 300 miles plus one way trip to add onto the cost , of cource miles won't stop me for "the deal" but you get my point. So here I sit trolling CL ect ect watching for my deal whereever it may be . Lets all find affordable hammers and make stuff! :)

chris -

guys thanks for all your help and insight on this. unfornautely the dream for me isn't going to work out on this hammer, finances just can't be done in the time frame needed. I have passed the info on to danger for his friend since they are local and spoke up first, hopefully we can do a follow up sharing good news from atlanta if they can make the deal work.

I don't post here often but read continually and love this site and really appreciate all of your suggestions and insights you have provided to a unknown character asking random questions.

So cheers and lets all find cheap power hammers :)

Chris -

great info guys I am currently in contact with a couple brokers to get quotes. pick up and palletization is the biggest issue as I see it today, it may still be bolted down as well so a bit more complicated than a simple pickup. I am going to continue with this for now and I'll share more details in the next 3-4 days. Pricing is potentially very low maybe half of the ones Larry mentioned and condition looks top of the line so may still be a viable deal but if I can't make it work I will PM or post infor for locals

chris -

thanks guys great info so far

chris -

So any one have shipping company suggestions for getting 100lb LG from Atlanta Georgia(30318) to Pullman Washington(99163). I understand it will cost but would this be super costly? Anyone have recent comparable equiptment shipping experiances to give me a cost range? looking at getting quotes in the next couple days to see if I can make the deal work.Thanks Chris

-

went to a farm sale today and got a few things

pile of old files for knives strikers etc, small craftsman ball peen, couple cresents big on is a SK nice vice grips, big old pair of pliers, small chisel head I will repair, old tire gauge marked US property ordinance dept, and a old unrepairable bent scale beam for the bronze/brass it has a nice S curve when viewed from the top. all for 10 bucks wish I had thrown more on the pile may go back and buy more tools if I come up with the cash . there were 2 post vices one welded to a small welding table I may make a offer on and another with u bolts for mounting it to the bench leg but not bad otherwise. had a pic can't get it to load now

may go back and buy more tools if I come up with the cash . there were 2 post vices one welded to a small welding table I may make a offer on and another with u bolts for mounting it to the bench leg but not bad otherwise. had a pic can't get it to load now -

-

Thanks guys , not sure why my search didn't turn up anything yesterday, today I got a few results. I now understand the limitations of this type of press if it was a bit smaller I would try just running it by hand as seen in another thread and youtube vid but I think this machine is too large, even as it is priced below scrap

chris -

So this is probably oversimplified but with the right dies and settings can a obi press be used in hot metal forging/pressing? the machine in question is a Johnson 27OBI press punch

chris -

Andrew, I have some I have listed for sale on here previosly here is the old add http://www.iforgeiron.com/topic/16341-wrought-iron-bolts-for-sale/page__p__166043#entry166043 PM me if you still need some and we'll see what we can work out.

Chris -

not me I rusted up in under a day maybe I am just caustic

I did the same thing cut a slice off the end of my first billet and forged it into a ring wore it one weekend and took a week to get the orange ring off my finger.

Chris

50lb Modern hammer

in Power Hammers, Treadle Hammers, Olivers

Posted

Crane truck inbound at 5pm !!! If all goes smoothly it will be running tonight. For temp on the concrete floor I was planning some 5/4 x10 oak planks under it I also have dense horse stall mat any thoughts on which one or both for a temp setup. Chris