-

Posts

228 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Timber Ridge Forge

-

-

Does anyone have a size or maker they prefer I am looking to upgrade for this cup stone I just bought and the little ryobi I got just won’t cut.

-

I wouldn’t pay $150 for that anvil but that’s just me.

-

Looks pretty beat up since you already have an anvil I would just keep looking till something better comes along

-

This is a guy Lesoutils Demagic I have seen who seems to be a large buyer and seller of anvils out of France he may know of some type of reference guide. If one exists.

-

It would but it took Richard postman something like 25 years to compile the information for his book. I think it would be very difficult if not impossible. To make a book like that it in countries minus the U.K. The anvils I see from those countries seem to be 1 offs and not masses produced and many are pre industrial revolution.

-

No worries man the anvils in America book is a great resource for anyone interested in anvils.

-

-

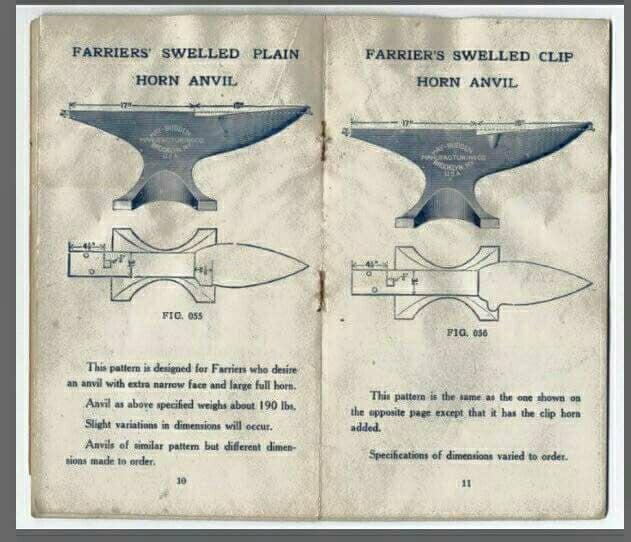

They are Hay Budden. Not trying to sound mean but I would suggest picking up a copy of anvils in America besides the fact that those are pounds not stone weight those are both well know Hay Budden designs. I buy anvils and sell anvils all the time.

-

-

It was a good week of hunting for anvils. I guess when everyone goes to the conference the midwest is easy pickings

First one is a 161LBS farrier Hay budden one edge is beaten up a little but a great anvil. The second is a Blackjack 100LBS Hay Budden. I have never had a chance two own either of these two so while they stay temporarily with me I will enjoy them.

-

If I were you I would find a collector and sell it they fetch a good chunk of change. Then take that money and get a nice 6" 110lbs ish post/leg vise.

-

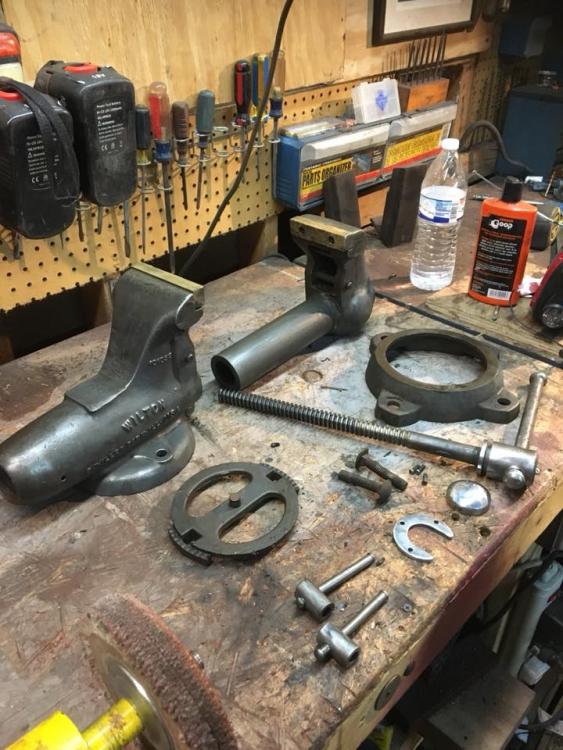

Wilton vise

in Vises

-

Wilton vise

in Vises

-

I actually have made a list of all the anvils I buy and sell with such information as dimensions, where they came from any history attached to them when I bought it and sold it also bought and sold prices as well.

-

I have heard from many people that they are cheap aso made in Mexico.

-

Yeah I am going to put it on the back burner for now unless someone offers me enough money to change my mind. I used it for about 6 hours last week and just didn’t like the rebound on it. I think it might be fine for some projects but I felt I was working a lot harder for similar results from better anvils I have. I also picked up a 144lbs Peter Wright farrier I have wanted to put in the rotation for a bit so it’s not the end of the world.

-

Well I guess it’s not as bad as I thought. I wasn’t as precise when originally testing as I should’ve been I took a ruler and droppedit at 10 inch to measure and got about 73% rebound on it I thought it was closer 50 originally.

-

It has a great ring.

-

I have quite a few anvils this was supposed to by my main one most are 115-160lbs this one has horrible rebound .

-

Wish you would closer jplserviceinc I would much rather have it fixed properly then patched up.

-

Trying to decide where to go with this guy picked it up about two months ago. I don’t need it to be perfect trying figure out what to do with it I think cost and time spent makes the Gunther method is not an option as I don’t have the skills or equipment to do it right myself might just cost to much between the fact that the rebound is horrible 50%ish on What’s left of the top plate. The section missing is quite large as well.

Options

1. Sell it to someone who understands its value properly repaired.

2. Weld up the damaged section and get a 1/4 - 1/2” top plate made and welded on.

3. Grind off the whole top plate and have it machined and add the top plate might cost too much.

4. Just sell it for the $800 I have been offered and walk away.

Curious what you guys would do. I am on a pretty tight budget at the moment so that’s a factor.

-

was only wet on the top to smooth it out

-

-

Yeah I got a demonstration coming up next month and I have never used this particular forge picked it up last summer and it needed the blower taken apart cleaned as well as a new leather belt all done now just waiting for warm weather.

Angle grinder

in Grinders, Sanders, etc

Posted

Good to know not looking for new since I go to so many flea markets and estates sales. Do you have any idea on price range for a used 10amp one?