-

Posts

108 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Ross Moffett

-

-

On 2/15/2018 at 4:09 PM, Shady McGrady said:

Quoted text we just read was removed<

Thanks for the reply.

I agree with you this guide system will definitely be stronger and work more smoothly.

I'll post pics once I've changed the guides.

-

-

-

On 2/13/2018 at 1:21 PM, the iron dwarf said:

Quoted text we just read was removed

Ok, Thanks, I'll get a new cylinder then.

How much HP would I need for say a 30+ ton press?

Do you think the design is ready or does it still need modification?

Regards.

-

On 2/12/2018 at 9:31 AM, Latticino said:

Quoted text we just read was removed

Thanks for the input, I'll see if I can get an engineer to have a look at it. Would you have any idea if the hydraulics off of construction vehicles and machinery would work for the press?

Regards.

-

Thanks for all the replies.

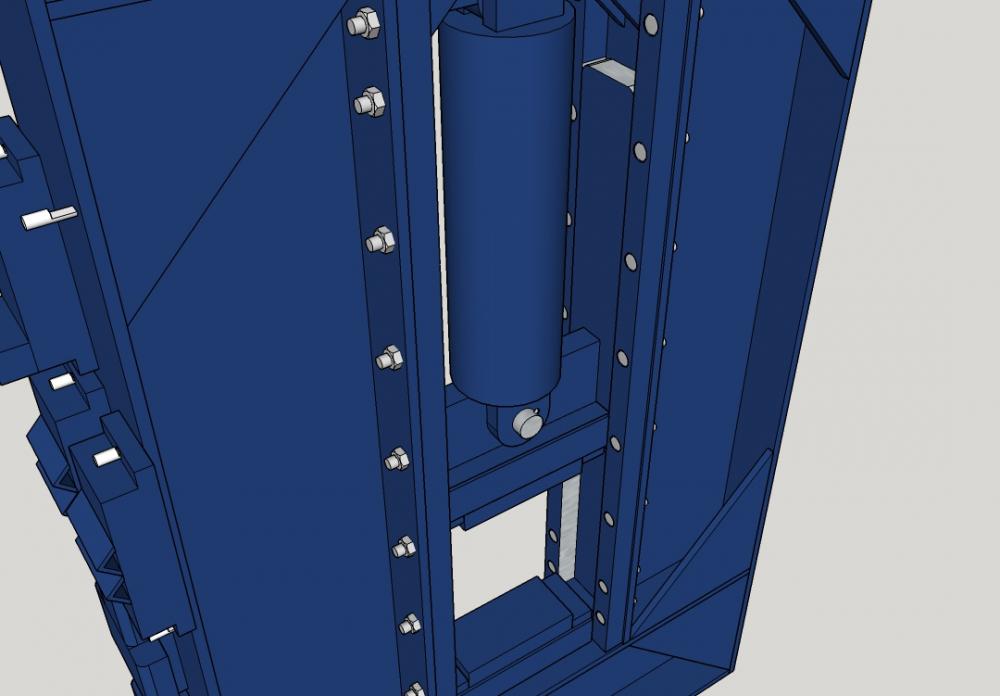

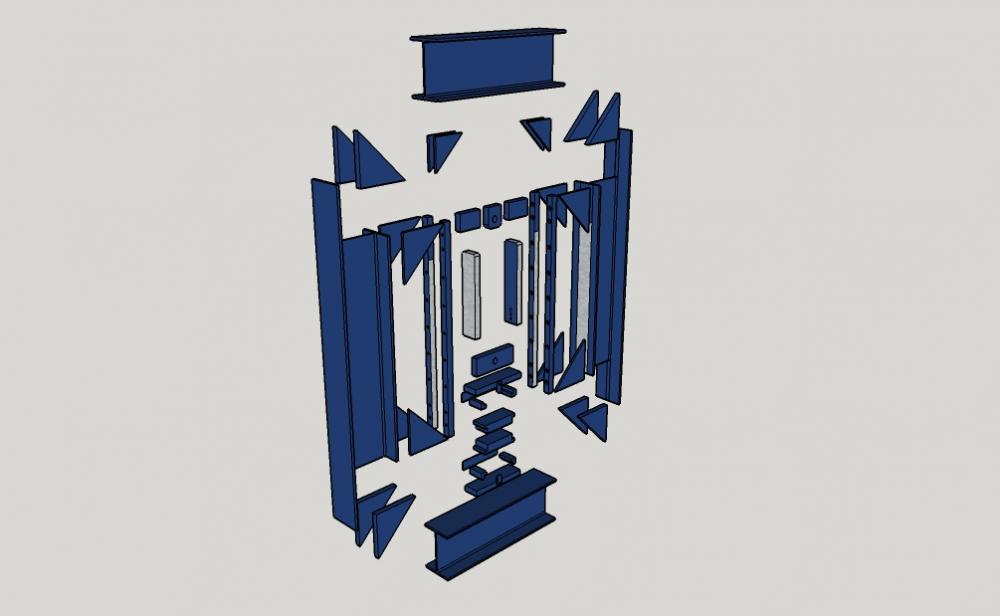

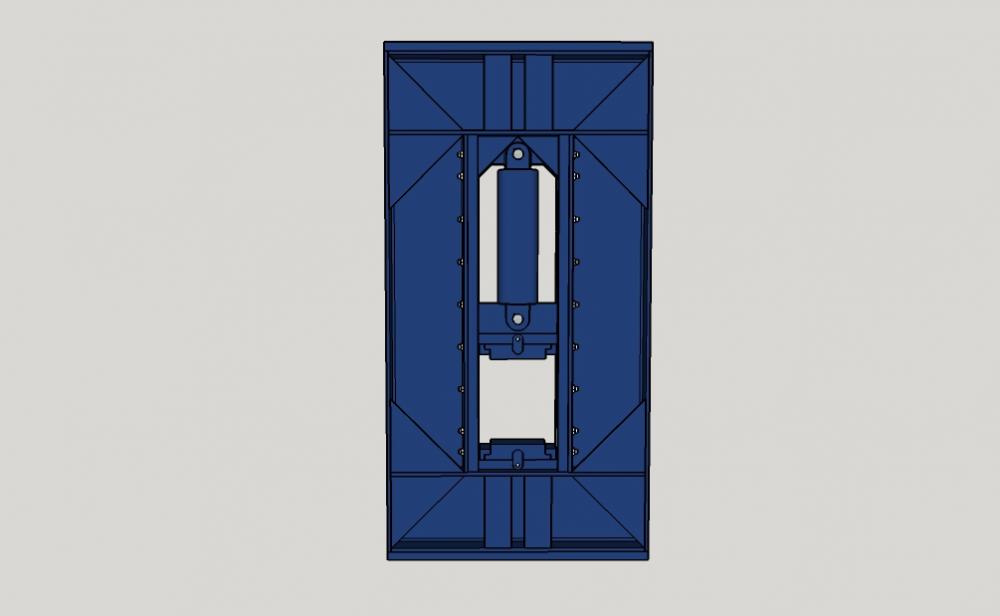

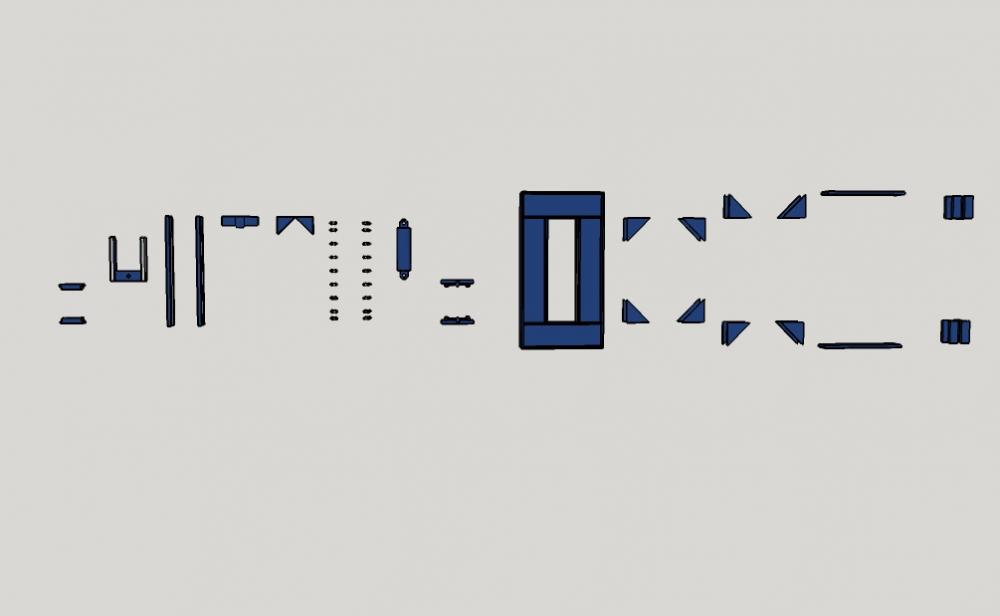

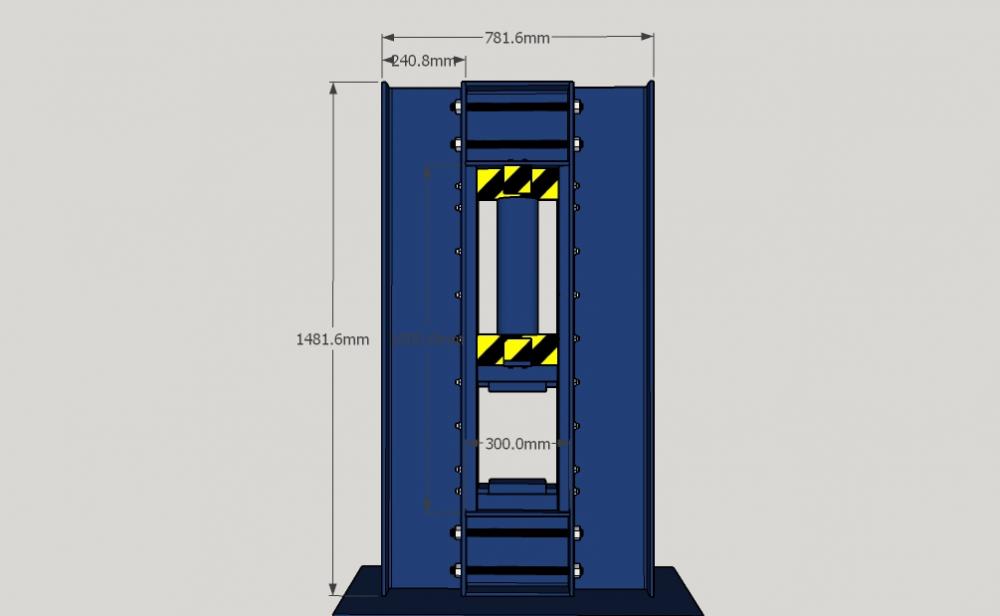

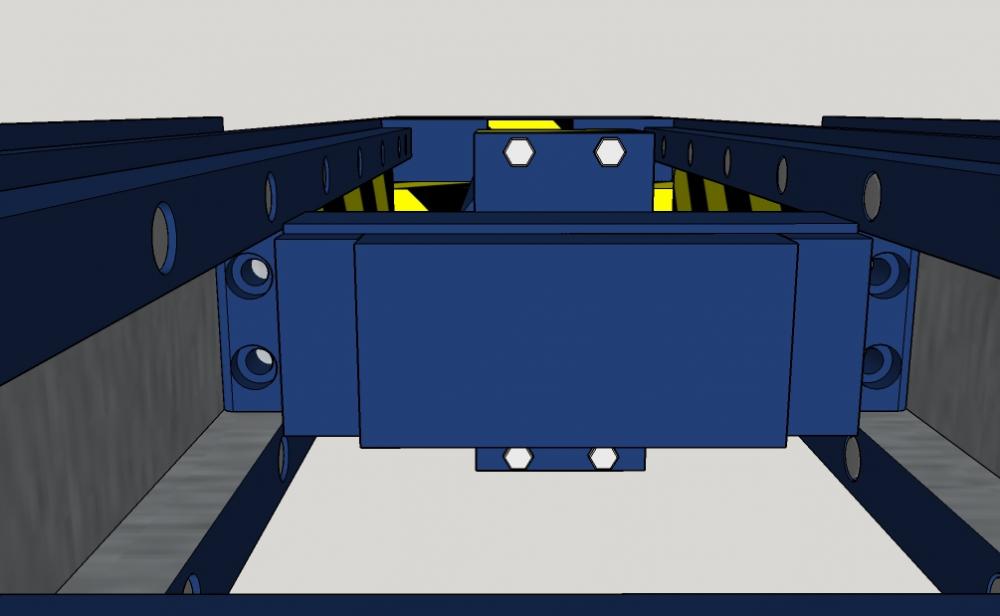

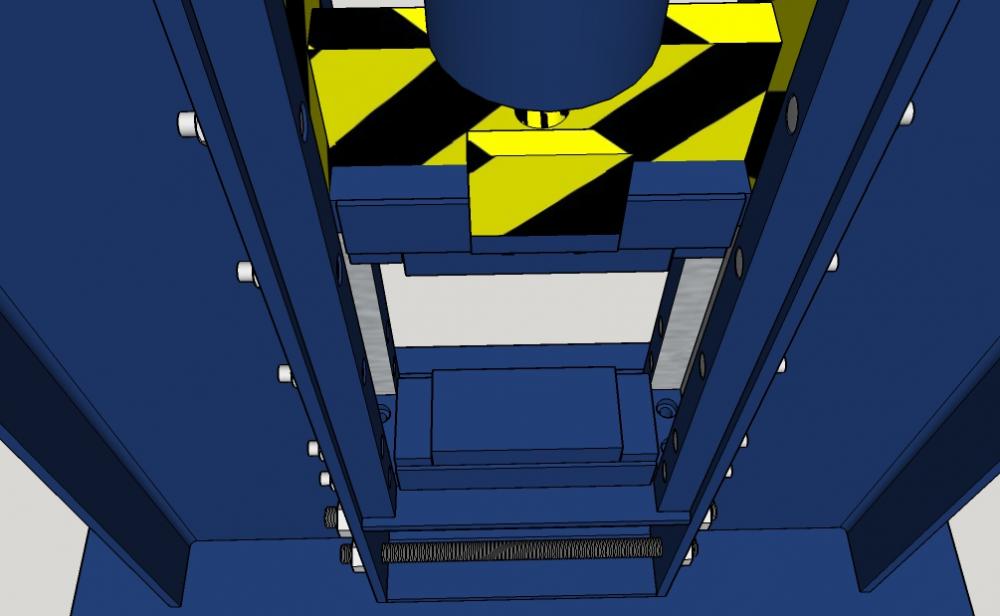

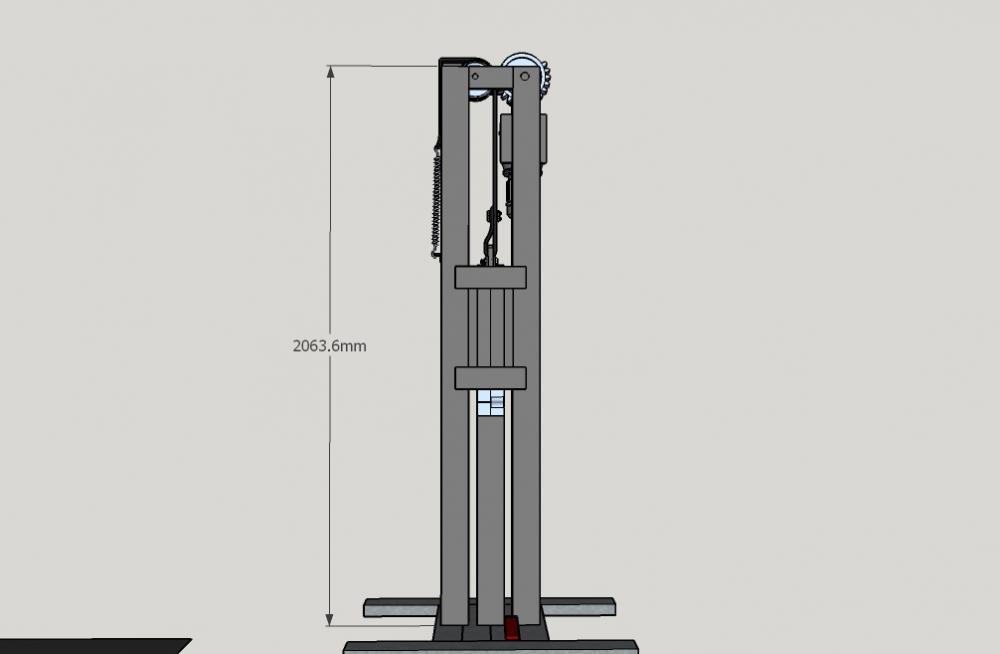

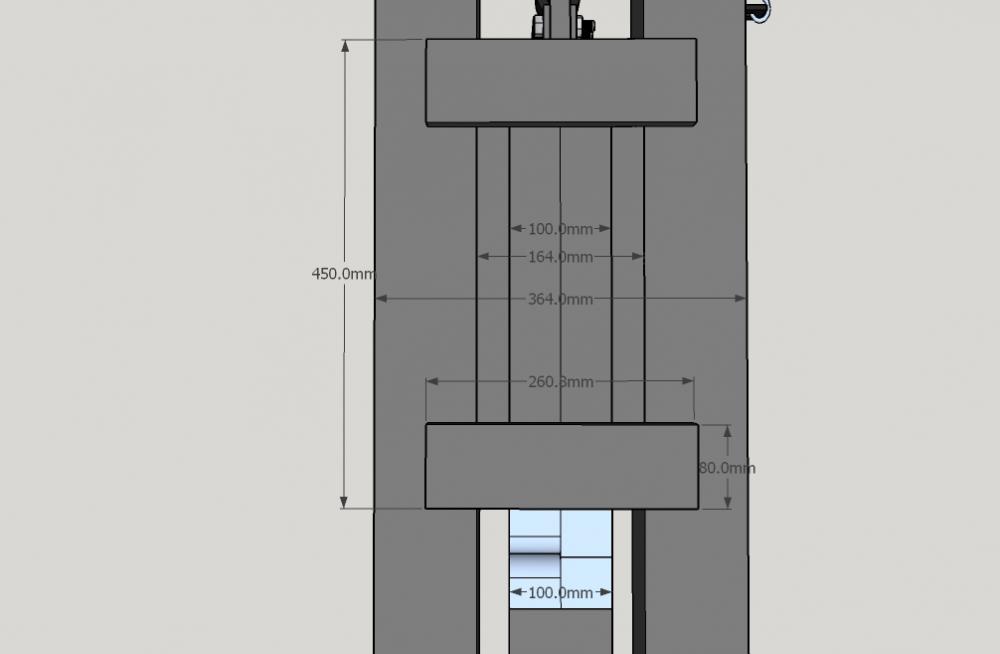

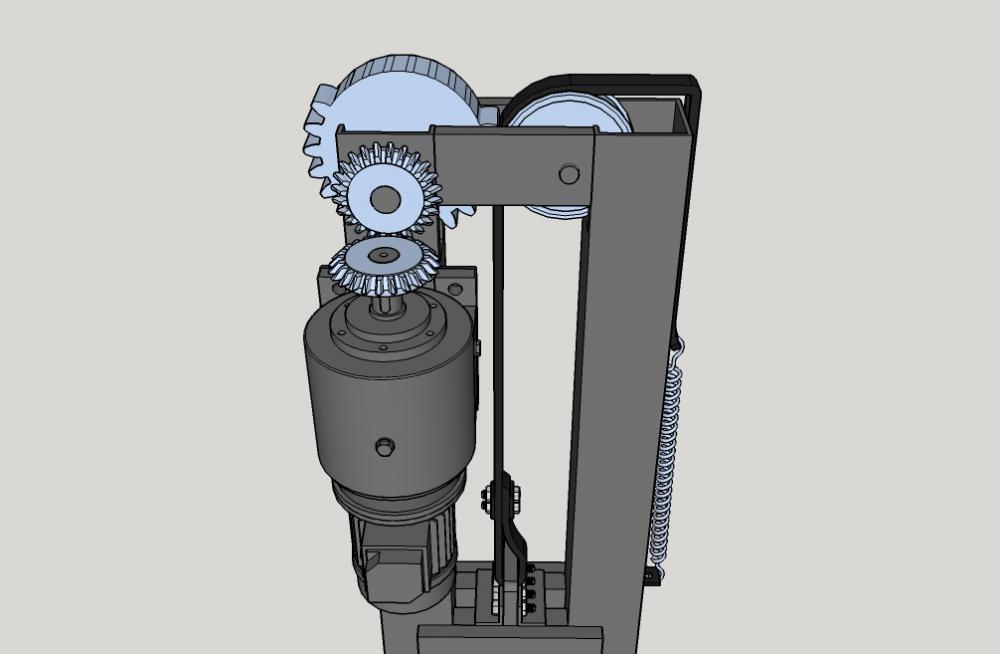

I've changed the design to incorporate your suggestions, please let me know if I have left any out.

Bore size: 120mm. Cylinder length 400mm, obviously this may change depending on what cylinder I can find.

I'm thinking around 30 tons + or -.

I'm planning on having the press on a base with wheels so it's easy to move around, the base will be around 1 meter high.

Once the design is complete I'll post it with a materials list and so on.

Regards.

redundant photos removed

-

I appreciate any suggestions and critiques to the design, I'd rather have this over-engineered than have something go wrong later on.

Is steel on steel fine for the guides or should I have something else there?

-

Hi Thomas,

I did not have a side panel but I will add one now and I will also change the all thread to bolts.

Thanks for the suggestions.

-

On 2/11/2018 at 12:07 PM, Latticino said:

Quoted text we just read was removed

My plan is to use the all thread to hold the frame together while I'm welding it and also as a bit of extra support.

Regards.

-

-

That's a very nice piece you have there!

-

48 minutes ago, jeremy k said:

Also look at the simple air hammer plans from the ABANA (American Blacksmith Association of North America) web site

Hi Jeremy,

Will do, thanks for the advice.

-

15 hours ago, jeremy k said:

Buy a set of proven plans and save yourself alot of trouble and questions, you can still modify them to your liking but you will save yourself time and everyone else's time. Also you will learn something by studying them, they are cheap compared to the build.

Ok ok, I'll see if I can get Clay Spencer's hammer design but I'm in South Africa so I'll ask him if he can email it to me instead of posting it.

Regards.

-

1 hour ago, ThomasPowers said:

Took me under 30 seconds to find plans for a 50# Tire Hammer just searching for Clay Spencer Tire Hammer Plans.

What didn't you just ask about finding a set in the first place? It's a well known version and many have been built and used already!

1Yes I know you can buy hammer plans but I'd rather get something for free since I'm going to have to change the plans anyway to fit the metal I have and I couldn't find anything for free (or am I just bad at researching?)

And I was going to design it myself but then I decided it would be easier to base it off of already made plans.

And hey I'm young and young people like to ask questions (even if they aren't the most thought through questions or the right ones)

Sorry for the confusion.

-

50 minutes ago, ThomasPowers said:

Ram size depends on YOU and what YOU plan to do with it and how much YOU do it. I would suggest trying various power hammers and try to build one the size you like the best.

The larger the anvil the more efficient the powerhammer. It needs to be 1 piece or constructed of vertical pieces, not stacked one on another and very securely tied together. (Look up how the iron-kiss power hammer anvils were made.)

Ram guides can be steel on cast iron, steel on brass, etc and so on...

If you have to ask so many questions are your really ready to build a hammer of your own design and not a design proven in already?

I think I'll go for a 50#.

I'll make the anvil as solid as I can then.

I've done research and watched videos and read peoples comments on power hammers but I just want a second (experienced) opinion on what I've heard, read and seen.

I'd love to get a proven and tested tire hammer design but I haven't found one yet.

Regards.

-

3 hours ago, ThomasPowers said:

Motors tend to be fairly easily sourced; I'd design the hammer to be built from what you have on hand and start looking for a motor in parallel. Using an overly large motor means upgrading all the electrical parts involved. My 60# Champion has a 1.5 hp motor but very large and old. The motor shop said if I was ever to switch it out I'd have to go to a 2hp modern one to make up for going from the large size to a smaller size for the torque.

I'll start designing then, do you think a 50-pound ram is enough or would more be better?

Must the anvil be solid and do I need something like Ultra High Molecular Weight Polyethylene in the ram guides?

Regards.

-

15 hours ago, Frosty said:

Am I right in deducing you're never used a power hammer? Your questions so far are what I'd call "blue skying." You have an idea but don't know enough to develop a workable plan. Yes? Just asking about a "drop hammer" implies you wish to do stamping work, say coining, OR you're just picking things at random. That is "Blue Skying" Nothing wrong with it but it makes for more questions than answers, I know I'm a blue sky thinker.

Okay, here are some things you need to read up on:

#1. What do you expect from the machinery? You need to be reasonably specific in your expectations. Drawing down isn't really the same thing as setting billet welds. This leads to list after list, I'll try and keep it simple. What size stock do you want to work and how do you want it work it?

#2. building on what you expect, how do you address your expectations based on your estimations of size and work? How heavy and or how fast do you want the hammer to cycle? Do you want to use combination dies? (that opens design questions to be addressed)

#3. Is there appropriate material in your Dad's scrap pile?

A tire hammer is just an easy to make clutch system for a mechanical power hammer. How you apply the power is the design question.

The way to go about this kind of design problem is to break it down into pieces and address them one at a time. Start with it's purpose, break it down. Next is to determine your resources, a LOT isn't very meaningful, WHAT is the important thing.

I'm not giving you a hard time, I'm trying to help you decide what you want or need, till you know you aren't going to be able to make good plans. It's really hard to help someone who doesn't know what they need or want. Okay?

Frosty The Lucky.

Firstly as I said to TP I've only ever used a power hammer once.

The reason I decided to make a drop hammer was mainly for the experience and because it is fun.

1# As far as stock size goes it'll mainly be Damascus billets about, 10 x 5 x 5 cm.

I'd like to be able to work the billets down quite quickly.

2# I think a 50-pound ram would be sufficient and at full speed around 2 hits per second.

I'd want combination dies.

3# yes, I don't think I'll have to buy anything, he recently had some old machinery and equipment taken apart.

The tire system does look easier than using a belt system, though I do have the available resources to do either.

I'll do some research and decide on what EXACTLY its purpose is going to be.

Thanks for your advice.

Regards,

Ross.

-

12 hours ago, Charles R. Stevens said:

I do think your on the right path with doing your research, Clay Spencer, and "old rusty" are two well known hammers that use a tire clutch, as as TP points out 4hp is enugh for a 4hp hammer

4I looked at Clay Spencer's power hammer, (very nice!) it's a 50-pound ram and running off of a "56 1 HP TEFC unit, wired for 110," (direct quote)

The motor I've got is a: Vetsak, 3 KW, 6.6 amp, 1430 rpm, 3 phase, 380 volts, 50 Hz.

Regards.

-

13 hours ago, ThomasPowers said:

Have you visited the shops of any of our other South African members?

No haven't.

I did recently visit a blacksmith (don't know if he's a member though) and used his power hammer and that's the only time I've used a power hammer.

14 hours ago, ThomasPowers said:Is 4 HP sufficient? Yes, No and Maybe depending on information you have not provided. I have a vehicle will a 55 hp engine work for it or do I need 111,744,000 hp? Why can't you tell me! (based on a vehicle we once owned and a vehicle that greatly impressed me; both could carry about the same number of adults.)

Should I design the hammer first then only choose a motor?

The metal I'm going to use for the ram is a 5 X 5 cm square bar, 45 cm of it weighs about 20 pounds.

Regards.

-

51 minutes ago, Charles R. Stevens said:

Tho not as compact I think the guided halves are easer to build, and the tire clutch is in the ground, I don't think that was a tire clutch, I think that was a belt clutch. Either way you have to have a spring to make up the difference in stock thickness.

I won't use that specific design, I'll do lots of research and then make my own and see what metal I have laying around.

Am I right in guessing that a 4 horsepower motor will be more than enough?

I probably won't have to buy anything since my dad has a rather large scrape pile and recently took apart some old machinery.

I'll start a new topic once I've started on the power hammer design.

Regards,

-

55 minutes ago, ThomasPowers said:

drawing with a board hammer will be tedious in the extreme, a powerhammer/triphammer will work much better. I have not seen one used to weld a billet before and so cannot comment.

Have you looked up how to build a tirehammer?

Just what I was thinking making a tyre hammer will be much simpler, (now that I've looked at some designs) cleaner and more effective.

Here's the link to a patent I found of a tyre hammer https://www.google.co.za/patents/US639538?dq=belt+drop+hammer&hl=en&sa=X&ved=0ahUKEwipi9vWy-bWAhVHC8AKHX2-D4E4ChDoAQhmMAk let me know what you think of it.

Regards.

-

2 hours ago, ThomasPowers said:

I'd think that all the patents on these things are out of date so you might browse the patent sites for drawings.

As for which is better: which is better a smart car or a dump truck? Without knowing the use case it's hard to know what will work better for it. Like steam is only good if you have a good supply of it already.

For the things I do a powerhammer and a scrwpress work better.

Well, the main reason I'm building it because it's a fun project and for the experience.

I'll probably be using it for drawing and for the initial weld on Damascus billets.

I'll have a look at the patents and see what I can find.

Regards.

-

Hi,

I've been working on a design of a belt drop hammer, but I'm getting completely befuddled on how to do it best.

What type do you guys think is best: steam, air, board or belt.

Yes, I have spent several hours looking at power hammer designs (and practically drooling I might add) but I haven't found anything really helpful.

Tell me what you think.

Regards.

-

Hi Jeremy,

Sorry for not replying sooner, but I'ver not had internet access for the last few days!

Nice press you have there.

Now I'm back home I can start looking what scrap I have available, then make a new design.

Ross.

.thumb.jpg.7d226250b736ae4caade9bae80cc9b04.jpg)

Forging Press Design

in Presses

Posted

Thank you!

Here's the updated design.

Let me know what you think.

Forging press.skb