andreas

Members-

Posts

54 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by andreas

-

Sure thing!

-

I like the way you think Frosty! If you square it with the wife I can likely find a nook in the shop for a second anvil. I paid $325 for my PW two years ago. Anvils go for $4 to $5 a pound for much worse condition than mine in my area.

-

Ok. Sounds good. If its good I'll buy it. Problem being there is not enough room in my shop for two anvils, and the wife would question the need for two so what could I get for my Peter Wright?

-

Wow, thanks for the fast reply. My friend wants $350 CAD for it. Any thoughts?

-

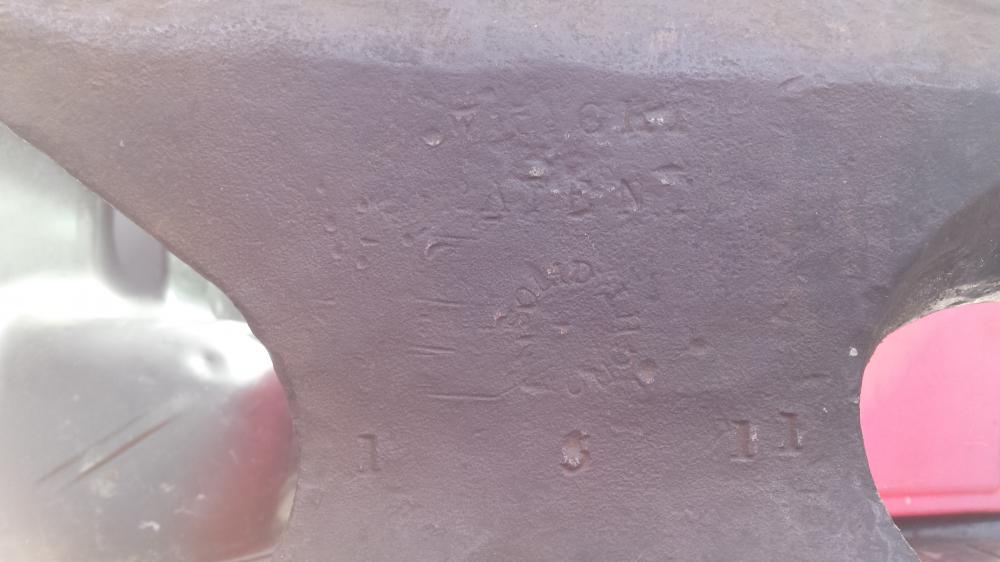

A friend of mine purchased this anvil but doesn't want it now. He says its English and weighs 189 lbs. It looks to be in better shape than my Peter Wright, but I can't read the name from the picture. Anyone have any ideas?

-

-

Finished except for final welding and paint, and hinges, and install etc. The 5/8 bent fairly easily, only needed a cheater bar on the tighter bends near the ends. Jig did the job. Another question though.... the frame is cupping up towards the welds, will welding opposite sides reduce this? Sorry about the sideways pic, haven't figured that out yet. The pulley was actually going to the metal recycle, but I thought it might come in handy for just such an occasion, which it did.

-

Went with the KISS principle. Kept it simple. Put my stock up against the block and bend around the form. Do a series of small bends for the more gradual curves. Working well so far.

-

Like your bender Dodge! So you're just making a series of smaller bends to get the radius you want I assume?

-

I was hoping someone would come up with some "I did that easily with.........." kind of story. Wishful thinking. I've never done something quite like this. I do have a small hydraulic ring roller I can try.

-

I am building a gate for a friend similar to the picture. My round bar is 5/8". Can this be bent cold? Should I jig or just try free hand? Has anyone tried something like this before?

-

Yes I bought the anvil. Did the rebound test with a 1" ball bearing . Frosty, you pretty much nailed it. About 8" (80% I guess) near the centre falling off slightly towards the tail and horn. No dead thuds or anything, nice crisp "ting" everywhere. Now I just need to mount it on something. Any recommendations there? Here she is In my shop. I was just going to mount it on a big piece of maple or something. Hardwood or softwood, any difference?

-

I did give it a few taps with a ball peen and it bounced pretty good. No dull sounds anywhere. Still going to try the steel ball test, just to be thorough. Just the German in me I suppose.

-

Got my 1" ball bearing, try the rebound test and see what happens!

-

I'm in southern Ontario. I have been to some auctions and seen smaller anvils than this sell for more. Going rate here in Canada is about $3.00 - $3.50 per pound, so even in the condition this anvil is in, it's a bargain. If I'm doing this correctly this anvil weighs 207 pounds (112 + 84 + 11). The rebound test, that the one where a 1"steel ball is dropped on the face and the bounce is measured? I can try that. What is an acceptable result? Anvils are quite scarce around here. Lots of people taking up the hobby. More often than not, the ones that do come up are in rough shape and not worth the asking price.

-

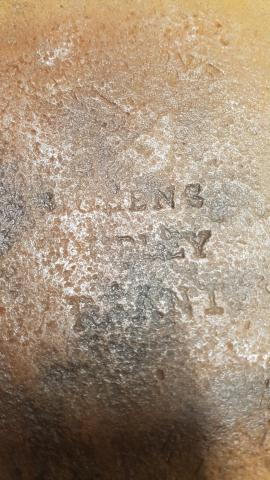

My brother in law just aquired this anvil. It's mine for $350 if I want it. It appears to be a Peter Wright, but the one side has a bevel on it and the name "Peter" is not there. All other markings are there, but that bevel makes me think that edge was damaged beyond repair and simply ground or cut away. Is this thing even a real Peter Wright? Still has good rebound and no dead spots

-

So, as to my original question, I'm good with hot rolled as long as it is heavy enough. Thanks guys. Carry on with the numbers / series / chemical compostion stuff.

-

I've been asked to make a fireplace grate for a family friend. I was wondering if there was any advantage to using cold rolled steel instead of hot rolled for this project. I've read somewhere that the cold rolled may last a little longer.

-

I think I have found the problem with this saw not cutting straight (running out to one side). The piece that tightens the blade into the bow (see pic) had been (poorly) repaired at some point, and as the blade was tightened, the blade became twisted. I made up a new piece and the saw now cuts straight and true. Thanks for the help.

-

John, gib key? shims? slideway? I have never heard these terms. What are they, where are they on my saw and how are they adjusted? Thanks

-

Bajajoaquin has it right. It cuts true front to back, but from the top down it runs out. Blade is brand new. I put a square on the base and checked the bar the saw frame runs on, it seems to be good.

-

Sorry about the pics. I've posted before and after pics here. I took it apart and cleaned it up. Fellow I bought it from used it in an auto body shop and it was covered in greasy bondo dust. I installed a new motor and replaced some bolts here and there. It cuts well and is true in the horizontal, but runs out to the left (as you stand behind the machine). I'm trying to figure out how to correct this.

-

I just bought this yesterday. Seems to be in good shape, although I don't think the motor is original. Anyone have any tips on how to set this thing up to work properly? Anything I need to watch out for?

-

Here's a vid of one of my burners. Seems to work Ok.http://www.youtube.com/watch?v=LxvPfaVmZK8

-

Does flaring the nozzle really add that much to the performance of the burner?