MarvinB

-

Posts

66 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by MarvinB

-

-

30 minutes ago, C-1ToolSteel said:

World's longest sentence?

Lol no time for punctuation

40 minutes ago, ThomasPowers said:Might have been AR plate for use in a coal conveyor.

Nah it's not AR plate I looked it up it came from Germany

-

2 minutes ago, C-1ToolSteel said:

Is it high-carbon? If not, that would make heat treating unessisary.

It wasn't high carbon I'm not sure what it was exactly for what it was being used for before I assumed it was good carbon of some kind before I treated it i could hit it with my rounding hammer and dent it so I treated it and it's harder than my hammers

-

-

-

Put the refract in it works just fine

-

Just curious to know if there's any bladesmiths/blacksmiths near me I'm in Kingstree South Carolina

-

16 hours ago, CMS3900 said:

The three main epoxies I see people use are West System G Flex, Normal West System, and Brownells Acraglas. There are also some blade maker specific epoxies out there now like Bladebond that I have heard positive things about. I have had good luck with normal West System, having used it in the past on boats. For knives I use the 206 slow hardener to give plenty of time to assemble and wipe down.

As for thinning, if you need to thin epoxy, your best off to heat it. Read more here: http://www.westsystem.com/ss/thinning-west-system-epoxy/

Bar tops are done the same way, once the epoxy is poured, you feather the top of it with a heat gun to remove bubbles, no harsh extra chemicals needed.

Always Mix on a flat surface too, not a cup.

As Frosty said, always wear PPE.

Thanks guys I've used a few there's just so many figured it be better to ask than winging it

-

12 hours ago, Frosty said:

What's the tare weight on the container and how empty can you get it? I'd just put ramps up and winch it onto the trailer, the less you lift a load the less likely you are to have something BAD happen. You'll need to put beams under it to get it to clear the fenders anyway and Connexes are made to be dragged. Steel on steel is low friction.

Don't get fancy, sure you can make the jacks plan "work" but have you considered getting the cross beams out from under it to let it down on the trailer deck? I've thought that plan to death many times over the years and it's more PITA than workable.

Frosty The Lucky.

5000 lbs and it'll be completely empty I'ma look everything over and see what the best approach will be

-

Looking for opinions on epoxy what do you guys use

-

10 hours ago, Frosty said:

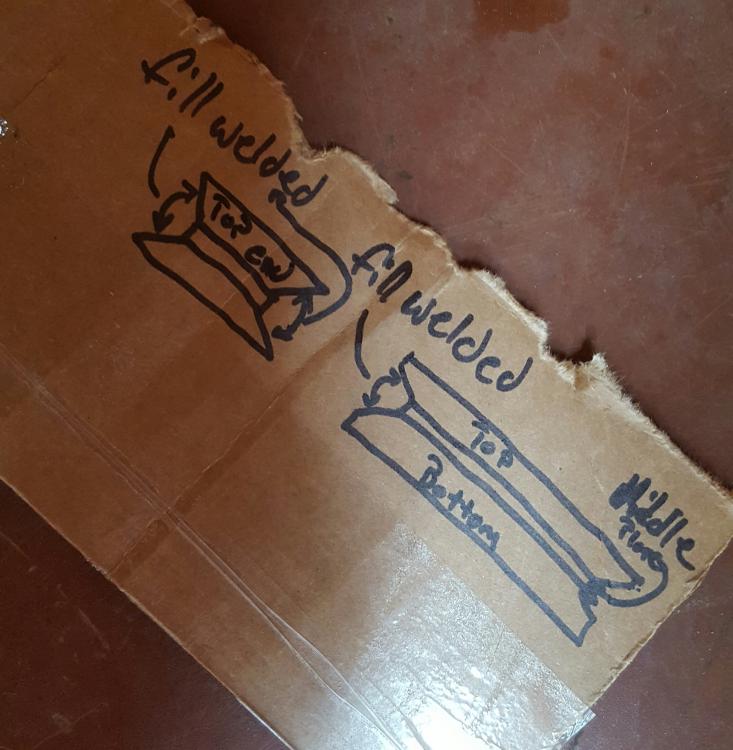

Nice Connex shed! Plenty of room under cover AND a lockable secure area. But be ready to pay for a slide back wrecker or trailer to move the container. Have the place cleared, leveled and ready to drop it. The rest is basic grunt work and doable solo if you're careful. The Connex makes an excellent secure surface to work off of erecting the rest of the shop.

Good score!

Frosty The Lucky.

We got a car trailer and we don't have to move it but about 6 miles we've been talking we've got 4 railroad Jack's think I might weld four peaces of 4" I beam off each corner lift it up back the trailer under it and off we go

-

-

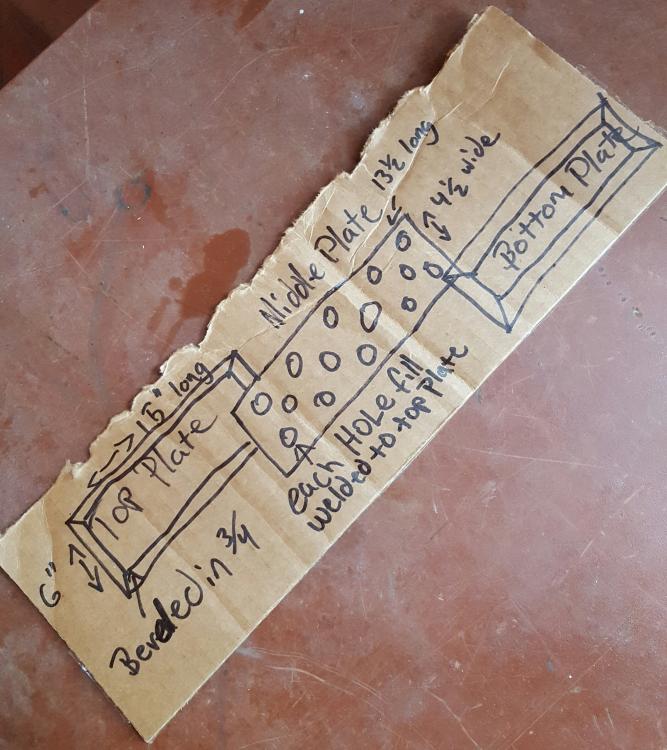

OK well before I joined this forum i watched a YouTube video on a simple forge liner you all know the one it didn't work the first time it would never cure just crumbled apart so I figured it was something I did wrong well I tried it again teaked it a bit let sit for a week still it just crumbled so I stuck it under the table and started collecting the material to do it right at this time I've joined up here well it's been sitting under the table for well over a month I pull it out with the intention of knocking all this crap out and doing it right well it set so I stuck a burner in it to see warmed it up its ok threw the gas to it stick a file in it 5 min is all it took I let it run it insulates good no heat on the outside I figure I've got money in it so I think I might smear some refractory over it see how well it does OH And I'm Not Trying To incurage anyone to use this because even if it does work out fine who has a month to wait on it to set lol I just so happened to say the heck with it and used coal I forgot to mention I put heat to it as well trying to hurry the prosses it just kept growing and crumbling

-

34 minutes ago, ThomasPowers said:

Of course these days it might possibly be a counterfeit of the well know maker too.

1 hour ago, Kozzy said:It's a I bolt so probably so

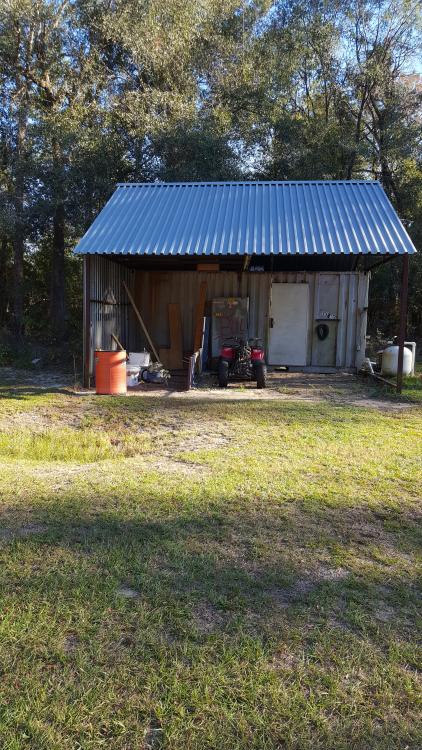

Does anyone know what type steel they use for I bolts ?I'm guessing it could be a wide range

-

-

3 hours ago, JHCC said:

Spark test. Forge one out and heat treat to see if it hardens. Temper it and snap it in a vise. Let us know how it works out.

Will do soon as I get a chance

-

They could be they came from a coal burning power plant

-

-

Hey thanks guys I actually ended up with 8' of 1" kaowool I wasn't thinking I weld tubes and pipe and there's kaowool everywhere it's what they insulate the pipe with

-

6 hours ago, Frosty said:

Marvin: If you're going to ask questions and expect folk to answer them you could at least READ THE ANSWER before asking another. It's just the sort of behavior that gets curmudgeons to say something harsh or just ignore you. If you aren't going to pay attention why should we waste our time?

Frosty The Lucky.

My mistake I didn't mean to skip over anyone

-

OK guys I've got kaowool I just didn't think about it it's all over the plants I work in I got about 8' that's 1" thick so will the sodium silicate work to bind it together and to the forge itself

-

Where's the best place online to buy forge liner kaowool/ceramic fiber

-

20 minutes ago, the iron dwarf said:

im no gas expert but think the refactory cement would not insulate it, two 1" thick layers of a ceramic blanket and a ridgidiser coating on the inside may be better

I made some sodium silicate not long ago you think that will work for the ridgidizer with the blanket

-

-

Just looking for a little aid I read on here that 20 Mule works but it holds moisture and there's another type of borax I don't remember what it's called that's better there was alot of talk about baking the moisture out of the mule borax not real sure

Frosty thanks for the info I guess I'ma do some experimenting

South Carolina

in Events, Hammer ins, Where to meet

Posted

Yes sir that's sufficient and thank you