MarvinB

-

Posts

66 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by MarvinB

-

-

-

On Sunday, September 25, 2016 at 3:59 PM, Frosty said:

Welcome aboard Marvin, glad to have you. That's a heck of a score for $50, I would've jumped on it and let Deb yell. I certainly wouldn't try refacing it. There has bee some serious delamination on the heal, two sizable pieces are missing. There's a high probability it's either delaminated or close in other places. Facing over a delaminated layer will cause the delamination to extend as a HAZ effect. Do you REALLY want to grind what face it has left off to be sure?

A lot of still usable anvils have been ruined permanently by experienced welders working in well equipped shops. There is just a LOT more to hard facing thick sections than laying down some rod. It's certainly doable but it's a LOT of work to do right, about as much as just making an anvil. Even a small repair takes a full day to preheat, weld, grind and post heat. Yeah, I hot grind with a cup stone to profile then finish with fine grit wheel and finally sandpaper after it's cooled. the NEXT day.

You ARE aware of the number of passes build up and hard facing rods are limited to yes? A guy can fudge it some but not a lot, especially with the hard face.

Yeah, I've burned maybe a couple thousand lbs of hard face rod and wire. There's A right way to do it and then all the ways some guys have been doing it for years.

Frosty The Lucky.

Glad to be on board

I agree as long as it dosent effect the rebound

-

On Sunday, September 25, 2016 at 3:59 PM, Frosty said:

Welcome aboard Marvin, glad to have you. That's a heck of a score for $50, I would've jumped on it and let Deb yell. I certainly wouldn't try refacing it. There has bee some serious delamination on the heal, two sizable pieces are missing. There's a high probability it's either delaminated or close in other places. Facing over a delaminated layer will cause the delamination to extend as a HAZ effect. Do you REALLY want to grind what face it has left off to be sure?

A lot of still usable anvils have been ruined permanently by experienced welders working in well equipped shops. There is just a LOT more to hard facing thick sections than laying down some rod. It's certainly doable but it's a LOT of work to do right, about as much as just making an anvil. Even a small repair takes a full day to preheat, weld, grind and post heat. Yeah, I hot grind with a cup stone to profile then finish with fine grit wheel and finally sandpaper after it's cooled. the NEXT day.

You ARE aware of the number of passes build up and hard facing rods are limited to yes? A guy can fudge it some but not a lot, especially with the hard face.

Yeah, I've burned maybe a couple thousand lbs of hard face rod and wire. There's A right way to do it and then all the ways some guys have been doing it for years.

Frosty The Lucky.

Glad to be on board

You all make good sense and I'ma take yalls advice and just use it it's got awesome rebound I'd really hate to loose it and for the time and money it would take to straighten it out I could just buy or build one

-

1 hour ago, jmccustomknives said:49 minutes ago, George Geist said:

Only do the broken part of the heel. Is no need to be worrying about the rest of the face. This isn't machine shop work. We don't worry about tolerances to the nearest thousanth. It'll be ok.

Yeah but I'd like to get the belly out of it think I might use it then decide what to do might just make a hardy tool out of this little rail I cut into a little anvil

-

21 minutes ago, jmccustomknives said:

I don't think there's an issue, but you might give it a layer or two of a build up anyway. That saddle is going to take quite a bit to build up.

Yeah its pretty rough I'm a little worried about how all the weld will effect the rebound

-

1 hour ago, jmccustomknives said:

Guys, the proper hard surfacing rod self hardens. There isn't a need to do a heat treat. I'm fond of the Nicromang which is a rod for building up RR track frogs that work hardens.

Thanks for the info I looked at Scoody 2110 rods it finishes at a 45 rockwell C and the 1105 finishes at 50 to 52 that makes everything much easier I wasn't sure about having to heat treat had a plan if needed to be

1 hour ago, jmccustomknives said:Guys, the proper hard surfacing rod self hardens. There isn't a need to do a heat treat. I'm fond of the Nicromang which is a rod for building up RR track frogs that work hardens.

The Nicromang is for manganese is it safe to assume the base has manganese in it ?

-

1 minute ago, George Geist said:

Do you have a Rockwell Hardness Tester?

It can fluctuate a little but since a hammer is around 50 you don't want an anvil to be harder than that so you shoot for between 45 and 48 R

I have a set of the rockwell files for testing not sure if that will be sufficient

-

Well I figured I'd build a hellva fire got a oak down in the back and already cut up should be plenty to get a large coal bed I'll have to build a rack to hold the anvil and so we can move it when it's time a friend of mine has a pump to put in the pond that has a fire hose I figure that should do it oh and I'll have to barrow 1 or 2 leaf blowers to help get it to temp

16 minutes ago, Thief_Of_Navarre said:That's what I was getting at really, perhaps I wasn't very tactfully.

*edit* If it is a mousehole you'll have to take it to meeting of the rivellin and the loxley circa 1920 to have the water flow to quench it sufficiently.

I figure that pump and fire hose should do it that things a beast but it may not

-

38 minutes ago, Thief_Of_Navarre said:

You would be better off making your own anvil then trying to reface that one. Unless you have 20+ years experience hardening anvils. There is plenty of workable face on your anvil

Well I've got 15 years experience welding I weld precision x-ray pipe and I don't know of much I haven't welded I don't think it will be a problem building it back up pre heat to 450 then use a stoody 2110 finish with 1105

-

5 minutes ago, jmccustomknives said:

I'd bought it at $50. It could be any number of English makers, there were tons of them. Mousehole was mentioned, they were bad about developing a "saddle". That's about as bad as they get. Still there's life in it and a saddle can be useful. You can always make a hardy tool that's a flat plat for flattening your work. Nice find.

I was going to reface it im a pipewelder by trade that's why I was trying to figure out what the base was made of so I know what rode to start with it moved it off the wood table and on to a center block has a nice ring so it must be steel but I hadn't thought about making a Hardy tool that'll save me some doe welding rods for this sort of thing aren't cheap

-

It dosent have any markings

-

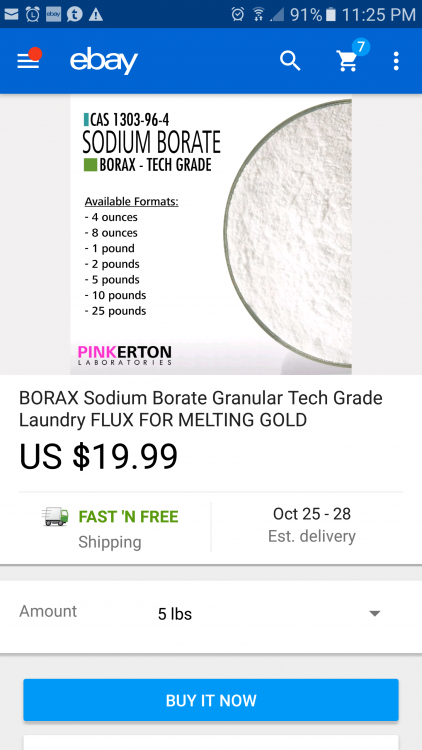

Will this be better than 20 Mule Borax

in Fluxes used in blacksmithing

Posted

I've got a few projects coming up was wanting to get the higher grade borax to see if it helps