-

Posts

94 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Derek Melton

-

-

I've been working on an order of key-chain 'Shepherds Crooks' for a local Bible college. They contacted me about the idea for a campaign they're running so I sent them a sample and they asked for 150 of them with the possibility for more down the road. I've delivered 20 and they're happy with them so I'm almost done with the remaining 130. I've worked up my tooling and forging steps so that I can turn them out fairly quickly, after all they're just little hooks.

I've soaked them in vinegar and wire-wheeled them and they came out nice and bright. Now I'd like to put a finish on them but the problem I'm running into is how to best go about finishing them in a manner that doesn't take forever to do but still leaves them with a durable finish. I've thought of putting them into an oven, getting them hot and then dumping them into oil but I'm not sure that will really 'take' very well. My primary forge is a small affair, an 8 inch diameter 12 inch deep propane job. In the past, to finish small items I typically hold them in the forge for a few seconds and then dip them in oil, beeswax or a blacksmith goop mixture of paste wax, linseed oil and shoe polish.

I've soaked them in vinegar and wire-wheeled them and they came out nice and bright. Now I'd like to put a finish on them but the problem I'm running into is how to best go about finishing them in a manner that doesn't take forever to do but still leaves them with a durable finish. I've thought of putting them into an oven, getting them hot and then dumping them into oil but I'm not sure that will really 'take' very well. My primary forge is a small affair, an 8 inch diameter 12 inch deep propane job. In the past, to finish small items I typically hold them in the forge for a few seconds and then dip them in oil, beeswax or a blacksmith goop mixture of paste wax, linseed oil and shoe polish.

If anyone has any good ideas, I'm all ears. =) I don't necessarily want to shortcut quality, even though they're small simple items, they're coming from me so I want to do my best but I would like to save time if possible too.

Thanks!

-

I had some scrap 1/4 inch round bar that I cut into 18 inch sections a while back. Whenever I get time at the forge, I try and start by taking a piece of this scrap round and making either a hook, or an S-hook. When I'm done, I hang the hook on a rail on the side of my forge cart and get to whatever project I initially started the forge up for in the first place. This takes me about 15 min, from the time I start the gas forge, to hanging the hook on the rack. Sometimes I turn the round into square bar before making the hook, sometimes I use a bending jig, sometimes I free hand the bends, sometimes I put a twist in it, sometimes I put a fuller here or there but every time I make one, I try and think to myself "make this the best hook you have ever made." It keeps me mindful and even then, some of them are terrible. I think I have 'good times' at the forge and 'bad times' at the forge. Some days the hook comes effortlessly, some days it seems like I never made one, not sure how to explain that other than because it's a hobby, and not my full time endeavor I do better at times than others. I think any time at the forge is good time spent as long as you stay mindful and have a goal in mind. Making a hook helps me with those two because no matter what happens with the project I came out to work on, at least I made another hook for a craft show down the road.

-

-

Oh. Yes.

-

I would most likely remove the top arm bar and make a cast of plaster or something else. I wouldn't wanna try and cast it in place either. Talk about awkward!

-

I have a rather large supply of pure lead. I wonder if I could take a cast of the hexagonal post and then make a lead mold for the balls?

-

Yeah, he's got an impressive collection. It's a VERY good thing he's a good, long way away from me.

-

I did! It was too good to pass up.

-

I just bought a Denbigh #4, it's on the way to me now. It's a tad crusty as far as paint is concerned but it's mechanically sound. It does need a counterweight ball added, which is being shipped with it (a large ball bearing I believe) I'm not sure how the counterweight should be mounted, I assume it's just a ball with a tapered hole in the middle? Anyone have any experience with "The Denbigh" presses? Anything to be aware of? I plan to tear it down, clean/strip and re-paint it. The table is a bit narrow but has a large plate with mounting holes to be secured to the floor.

So far, this year I've added some great tools to the shop including a much nicer Swedish anvil, an Inline treadle hammer and now the Denbigh flypress. Super excited!

-

Thanks guys, I'm still learning!

-

-

I may have the opportunity to buy a 25# Little Giant in the near future. It was in running condition last I'd heard just a few months ago. I've seen some pictures of it but have not seen it in person, yet. The pictures show that it seems mechanically sound but it is nearly completely covered in heavy black grease and bits of scale. It looks like it would be difficult to determine the true mechanical state of it, any cracks, etc without doing something like a hot power wash to it. Is there any danger of doing so? (besides the danger to the 110v motor attached to it)

Thanks!

-

17 minutes ago, beammeupscotty said:

It that a Canarywood handle?

Good eye!

-

I just spent 3 weeks recovering from scale that popped into my eye when I was twisting some small barstock. It got embedded in my iris and had to be removed and then a small area of my eye had to be drilled to remove rust-infused eye tissue. I do not recommend it. It was not pleasant and I'll never go in my shop without eye protection again.

-

4 minutes ago, ThomasPowers said:

If you find that you are selling most of your stuff during setup or teardown days then you know that you are generally selling to other crafters and *they* think your stuff is well made at a good price.

I've sold only one so far but I've given several away to close friends and asked them to use them and report back any shortcomings, etc. so far, this is the only one that has failed and it failed before it left the shop so, it's served a pretty valuable purpose already.

-

3 minutes ago, stockmaker said:

Nice little hammer Derek. Having the right hammer for the job is not only important in blacksmithing, but in other endeavors as well. The right little hammer is as important to me as the right chisel or file. I have wondered lately if there is a market them at craft shows? A picture of my workbench this morning.

Thanks! I love doing it and while I'm still a rank amateur, I want to learn and make each one better than the last. I think this is hammer #11 so I've got a long way to go. =)

-

17 minutes ago, Derek Melton said:

Yeah, 99% of my experience with 5160 has been with knives. I've made some punches and hand held drifts/fullers with it but I usually temper those by color. What would you suggest for a temper? Just bring it to a straw and quench or pop in an oven for a particular time/temp?

I probably answered my own question there, I probably should just heat treat the working faces, temper by color as I do with other 5160 hand tools. Once I get the next hammer finished, I'll test it on the anvil too and I'll know if my process is working or not. =)

-

6 minutes ago, ThomasPowers said:

400 degF? That's more a knifeblade temper range and not an impact tool temper range!

400 degC? (752 degF) would be kinda hot for an impact tool of that alloy...

Yeah, 99% of my experience with 5160 has been with knives. I've made some punches and hand held drifts/fullers with it but I usually temper those by color. What would you suggest for a temper? Just bring it to a straw and quench or pop in an oven for a particular time/temp?

-

I agree, larger stock forged down on the ends would work better, I was just curious as to how one would turn out, somewhat as a novelty, from such small round bar. I was really pleased with it. Until it broke. This was my first attempt at the tiny hammer. Being 5160, I just heat treated it as I always had, heated to critical, quenched in oil, tempered at 400. The grain structure of the steel where It broke looked just like a file, kinda creamy and fine. I think it was just too brittle and my temper didn't work out.

I worked on a new slit/drift combo for the 3/8 round bar last night. It worked well, I really appreciate the suggestions from Alan Evans regarding the proper diameter of the drift in relation to the stock. I'm going to make the same kind of tiny hammer, this time I'll keep the eye a little smaller and I'll only heat treat the working faces, not the eye material.

-

Wow, thank you! I made a new slitter/punch last night that was the same 3/8 diameter. I forged the end down to a typical slot punch shape and then I cut it about 3 inches short and welded it to a 14 inch section of 1/4x3/4 for a handle. I plan on trying it tonight. I'll post here with results.

-

I've been making some small hammers for jewelers and knife makers who need small, delicate hammers for detail work. I've been asked to make them even smaller, so I'm considering some from 3/8 inch round bar. Anyone have ideas for tooling, techniques for punching eyes in small round bar? It's kinda tricky. =)

-

I do like that Batson design with the heavy angle, seems like the fabrication would go fairly quick. I think I'd probably go with a single cylinder for cost reduction though. I think 1500$ is the sweet spot and I want to get as close to that as I can and still have a press comparable to the 3500$ commercial models like the Coal Iron works and Uncle Al's

-

Those questions are still being tossed around right now. Personally I don't want to make anything less than 30 tons and favor the H frame for strength.

-

2 hours ago, setlab said:

A concern I have is the quality of the welding that will go into it. Before I built a power hammer, I read and searched for every hammer group build out there and a some of them left me a little wide eyed from the atrocious welds. I'm far from a professional welder myself but from everything I've read on building Forging presses weld quality is a pretty big safety issue.

We have at least a couple of professional welders in the group I believe. I won't participate in a build project that doesn't have adequate welding.

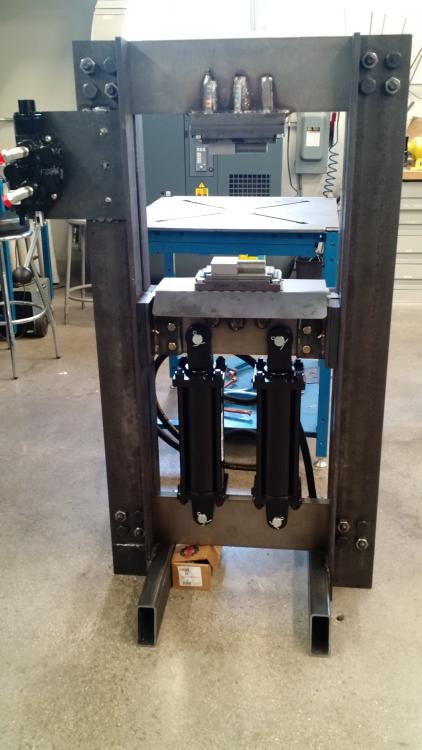

13 minutes ago, rhitee93 said:Just to give you a data point on your costs, I am nearing completion on a 40-ton dual cylinder press. This will be powered with a two stage pump that is 22/7GPM using a 14hp Brigs engine.

I purchased everything new

I had the large structural steel members machined at a local shop to the tune of about $500 (They supplied the steel)

My total cost at this point is close to $2k. I think with some economies of scale and clever buying, your price point is pretty close.

This is where I am today...

Thanks! That is an amazing looking press. What made you decide to go with dual cylinders?

![20170412_083048[1].jpg](https://www.iforgeiron.com/uploads/monthly_2017_04/58ee4ea9b5d5d_20170412_0830481.thumb.jpg.5b5ae0b4ff8c69bf2ade940c5a0216a9.jpg)

Ideas for putting a finish on multiple small items?

in Finishes for Metal

Posted

Yeah, if I was starting over, I'd probably do that. I've got them all forged and wire brushed now.

This is one option that I've thought of a good bit. I may lay them out on a board, spray them, flip them spray them again and call it done.