Bully

-

Posts

128 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Bully

-

-

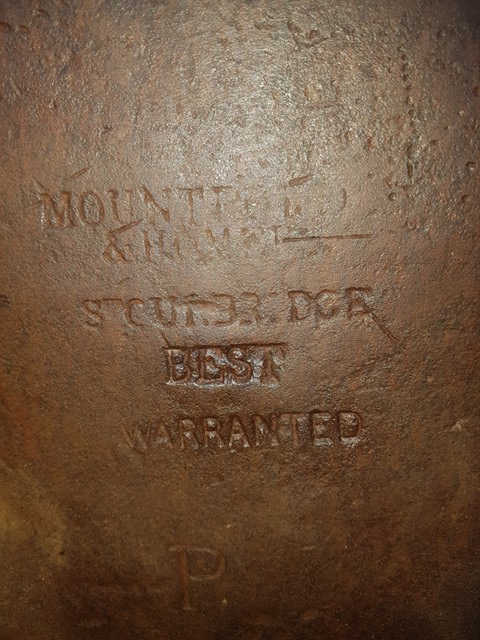

Hello all can anyone ID this anvil maker/origin for me has the wording 'Hardware 1 1/2 raised on it. Its cast with a hardened face rings very sharp and crisp and rebounds fantastic. At a guess I would say weighs in about 160-80 pounds Thank you Bully

Whoops spelt Hardware wrong its 'Hardwear' as per pic ...sorry

-

Hi all I'm in the process of designing my new Smitty on my country block and although I have a hand cranked blower I also have a 12 volt solar power system and wondering if anyone has removed and connected up a fan system from a vehicle to use as a blower. Cant see it not working at this early stage..... variable fan speed etc so wondering if anyone has done the same and how successful they have been and /or tips on doing so or would I be wasting my time. thanks

-

Thanks it was a lucky find the last number to the best of my eyesight is a 9 or 19 as a whole cheers how far North Qld I have a brother in Mossman (just past it) and everytime i visit i cant help but think how hard it would of been for the smiths back in the day with the humidity but hey they just had to do what they had to do

-

Thanks to all once again a wealth of knowledge had never heard of 'Mountford & Homer' so perhaps thats what it is and looking at the picture that name does tend to appear be it faintly cheers.

-

On 1/6/2018 at 3:57 AM, C-1ToolSteel said:

Beautiful anvil. "Stourbridge" is the English town your anvil was made in.

Check this thread out for a Stourbridge add that lists "Mountford & Homer" under "Vice and Anvil Makers".

BTW, I counted at least ten pick heads in the background. Any story behind that?

use to work for a scrap metal company and just could not bare to see a pick/hammer/axe/shovel etc etc etc be thrown into the incise bin to be carted of to China to be melted down so I rescued what I could which when I look around my yard I must have 500 + of the above combined. Some I resharpen polish up re handle and give away as presents ....

-

Hi Guys and Gals firstly all the best for the new year may it be a rewarding and safe adventure. I recently purchased a London pattern anvil with the following stamps and struggling to id the origins of the maker Mount??? & Ha????? any info would be appreciated as it has me stumped and I consider myself a fairly good researcher hence why I now ask you all. cheers.

-

5 hours ago, Frosty said:

I strongly suggest you mount it high enough it's never lower than the fire pot or unburned gasses CAN back up into it. Backfires have been known to blow bellows into pieces.

Frosty The Lucky.

Thanks was intending to have them approx a foot above fire pit.

-

-

-

Hi all, have not been on for a long time so hope all are well, this topic may and probably has been explained before but can anyone explain to me the actual difference and process it takes to get coke from coal.. My understanding is coke is refined coal. But how do they refine it Thankyou

-

Great work something you are no doubt proud off and so you should be cheers ps now looking at my yabbies in my fish (yabbie) tank in the lounge room mmmmm wonder if I could do that,,,thanks

-

Fantastic work would love to see it in the flesh

-

Scrapartoz I have just viewed your works and you are the 'king'. I have been dabling in creating works from scrap metal for some time and have sold some, given some away, and have been told I am good at it, but you my friend are awsome ( I just got my wife off the couch to show her your works as she knows how much time I spend out the back and she now realises the time spent and size of my works are minor in comparrision to yours.) I drool at the rust coloured 'gold' you have lying around and could only dream about walking out my back door and into my workshop to create. Fantastic keep it up. Cheers Bully

-

This site is all about sharing and caring and helping other smiths etc but the humour at times is also welcome and and I must say ANVILFLOWER I am still laughing at your reply post ie Not an essential part... as long as you don't plan on using it as a vise. LOL cheers

-

make your local scrapmetal dealer a sculpture from his scrap and bingo bango free metal worked for me cheers

-

WOW I a feelin a bit exposed. Have not been on Iforgeiron for some time and when I do well what do I find only 2 B/S left in Aus

I had better get the kids a hammerin and attempt to build the gene pool up mighty quick, not to mention they love the idea of wearing tightds and flying around the world in rockets and living on a islands. WoW bring it on. -

Yes nice coat rack may try one myself

-

Ha yeah sucked in and although "downunder" thousands of kilometres away I still wondered if there was a bargain I might be

able to get my grubby mitts on. Cheers -

Well said Ian and Sukellos, I know myself Dale is very passionate about blacksmithing and to be of the tools for the time that he has is no doubt getting him down, I am hoping to make a visit next week and if I find him sulking around I will attempt to put my size 9 you know where and then while he's trying to catch me (I reckon I can run faster than him but in saying that the old boy is full of surprises) I will remind him that postive thinking brings positive results. Thanks for your thoughts for him so far away if my size 9 does not do the trick give me your sizes and I will forge a kicker with attatchments and eventually he will get the message (or me) cheers Bully

-

Nice I myself still having trouble with the welding side of things but again as with this craft trial and error and learning from mistakes are what makes it so challenging and rewarding keep it up cheers Bully

-

Hey Dale chin up sell nothing, have been trying to get over to your place but work, kids and unforeseen committments keep appearing

You know your always welcome here. Cheers Bully -

I have dirt floor which worked ok until I thought I would pour a few bags of breeze (coke dust) onto it just to keep things 'nice' and colour scheme uniformish. Big mistake dog is always black, when it rains and I leave the forge black fooprints everywhere, dust is worst now than before. Have tried wetting it a few times and letting it dry before I step on it in the hope it would harden and does for about 10 minutes. Oh well one thing you learn from blacksmithing is you live and learn. Cheers Bully

-

Thanks Gents, Dale played baseball in Ballarat (Druids) for 4 years running ending up as shortstop, great game, and Bob yeah I use to spit on my glove and sleep with it under my mattress. As for the leather on the bellows it has split at the stitching and has a few small holes in it so will wait until it softens before I attempt to either re stitch and/or patch so meanwhile I have forged a stand for it and its upright in the loungeroom (missus just shakes her head now). It is a double chamber and even with the damage it still blows a incredible amount of air. They sure knew what they were doing when they made em. (Catch up soon Dale for a chat) cheers Bully

-

My Mums from Britain and I give her ironwork I have made, I myself have also met the queen, and although I am in Australia does that count??????

Anvil ID maker

in Anvils, Swage Blocks, and Mandrels

Posted

i think this brand has stumped the anvil community re its origins, thats not a bad thing I find it interesting that its limited considering the wealth of knowledge we have on IFI. With the prices that Australia has on anvils this one may well be worth $$$$$$ lol still no hurry to sell its a nice tool. keep on smithing and bring back to the uneducated how blacksmiths were pivotal in creating communities, towns and societies as a whole...respect gents respect