Hawgdirt

Members-

Posts

52 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Hawgdirt

-

Well that's what I was trying to follow was his video, I'm not getting something right though.

-

I'm sorry but I think I got the name wrong, they're called Flat nib tongs, might be the same as wolf jaw tongs but they're made from rr spikes. I have coil spring but my anvil isn't anchored enough to uncoil them. Think some bolt tongs might be easier to forge.

-

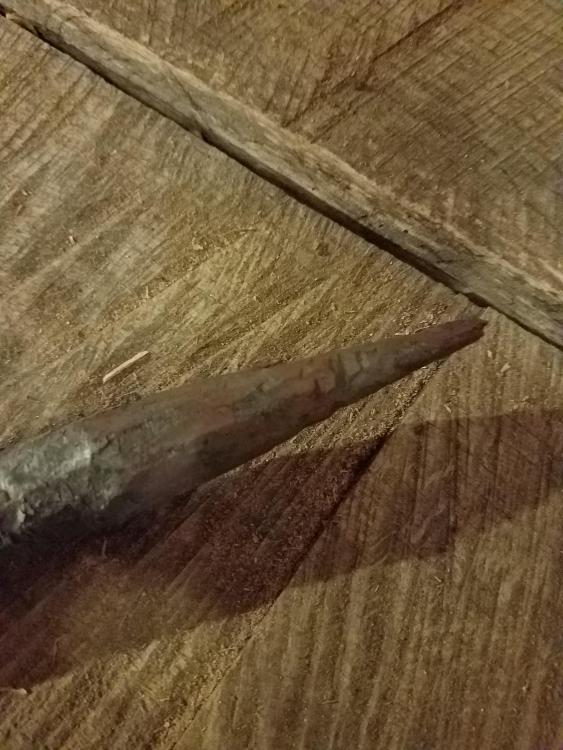

I've been trying to forge some wolf jaw tongs out of rr spike. Right now I'm on my 6th or 7th attempt, I'm getting better but having trouble getting them to set together. Probably not the easiest style of tongs for first pair. I understand the concept of the setdowns but can't get them to fit. Here's some pics tell me what y'all think.

-

Bahaha, that's funny, I couldve swore that the guy on the video punched it in the bend. Oh well.

-

Didn't get much forging done. Tried out anthracite coal, didn't work too well for me by itself, worked great mixed with bituminous. Blacksmith supply in my area sells bituminous for a whooping $35 for 50lbs. Took my hand crank blower off and put on a bathroom fan from home Depot. Was a little concerned about air flow but it got 1" pto shaft white hot fairly quickly. Guess coal doesn't need massive airflow. Did practice making a punch but mostly just updated my forge. I Also put a picture of those tongs I tried to make and a half done hammer punch.

-

Awesome information. Yea a decent hammor is what I need. I'm going to home Depot to get me a 2lb cross peen, one I got is real old and the handle is like 6inches long. I had plans of making all my tools but I need a hammer. I'll post a picture of my half finished tongs tomorrow. And I made a punch today, it did punch a hole but kept folding over and I made the taper too long and used soft metal. Going to scrap yard tomorrow to get some bethere metal. This is way off topic but my goal is to make those real nice looking brazeal hammer but all the videos show 2 people working together. I can do all of it by my self except the fuller part. Can you use a fuller without a striker?

-

Ok well ill head to the scrap yard in the morning and get some coil spring. I was planning on making my own tools but if tongs and hammers aren't good for beginners, what are some good beginner projects.

-

Thanks for the info. trying not to complicate this but the only difference between a punch and a drift is that a punch has a point end correct?

-

I forged the tongs out of 1/2 rebar. Figured that'd be thick enough. I do have a 1" axle I could try and use but I think that might be a little much to try and draw out. I could forge a punch from the axle. Guess I better start with a less complicated set of tongs. I just needed something that would hold 2" axle to make a simple cross peen hammer.

-

I just started smithing and for my first real project I'm make a pair of Brian brazeal hammer tongs in preparation for making a hammer. Too my surprise they turned out decent up until the punching of the hole for the rivet. Number one I used 3/8 smooth stock from tractor supply, spice l should've used 1/4. I made a punch from that 3/8 smooth round from tractor supply with a long taper. Problem is it keeps folding over everytime I use it. I did manage to punch a hole on one but it has very little meat keeping the hole in tact on one side. I guess it will work. Do I need a different metal so it won't fold over or do I just need a short fat taper?

-

Yes, I believe that 2 week course is put on by the abs, it's at the texarkana college. It looks like a great class, they say at the end of it you should be able to make a blade well enough to pass the journeyman test. I found that a little strange, go from 0 to journeyman blacksmith in 2 weeks? I dunno about that. This question is completely off subject but how do you search the forums correctly. For example I wanted to look up belt grinders so I searched and it gave me every post that had ever been written that had the words belt and grinder in it. I was wondering was there a way to search a little more precise. Like if I search for belt grinder I want the threads that have to do with belt grinder not just every post with the words belt grinder.

-

I've been bouncing back and forth between solid and gas and have decided to go with solid. Then it was between the box of dirt and 55 forge. Well I've decided on the 55 forge but had a few questions. 1. The images look like the tuyere is blowing on the fire, is this how it's supposed to work or should it be buried in the coal. 2. It also looks like before you start forging anything you need to build up a layer of ash almost to the tuyere, am I correct in this assumption? 3. Can you forge weld or make Damascus as this is what I hope to get to one day. I had a general question about learning this trade also. I was considering taking a 2 week class at a tech school for $1000. Is that necessary or will I be able to learn just as well by hammering metal on my own? Really excited to get started, been working on my shop for over a year and almost done, hopefully I'll be hammering soon.

-

Looking to get into blacksmithing

Hawgdirt replied to Hawgdirt's topic in Blacksmithing, General Discussion

Been doing some reading and decided on a side blast forge. I've searched for Glenn's 55 side blast forge but all the links I find are not working for me. Was wondering if anyone had a working link to the BP. -

Looking to get into blacksmithing

Hawgdirt replied to Hawgdirt's topic in Blacksmithing, General Discussion

I completely agree with you, I know my idea of a forge is not of importance right now. And I'm sure some of this will come with experience but I have no clue where to get materials. Like a old brake drum, no clue where to find one. And I've seen videos of smiths making axes from a chunk of steel welded on a stick. Do you buy that type of stuff from the internet? And before I get my hopes up for one day being able to call myself a competent blacksmith, is this a skill you can learn on your own? No apprentice programs where I live. And can anyone recommend a good book for beginners to learn about blacksmithing? -

Looking to get into blacksmithing

Hawgdirt replied to Hawgdirt's topic in Blacksmithing, General Discussion

My biggest obstacle I'm having right now, and it's very stupid I think. I feel like my first forge should look like a traditional brick forge you see on TV. I realize that I do not need something extravagant like that as I don't even completely understand how a forge works. I was leaning towards propane as I didn't know I had a blacksmith supply store in town. They sell 50lb bag for $35 is that reasonable? Would 50 lb last awhile? I suppose a brake drum forge would be good for a beginner? I've seen hundreds of videos on making them, any in particular yall recommend? -

Looking to get into blacksmithing

Hawgdirt replied to Hawgdirt's topic in Blacksmithing, General Discussion

I'm from Blanchard, LA I'll be sure to put that in my profile. My dream is to be able to make custom axes for people like John neeman or gransfors bruks. For now I just want to make axes, knifes and other general tools. And yes I just found out we do have a blacksmithing supply shop in town called Emerson. -

Hey everyone, I'm sure this question has been asked many times before. As soon as I get done building my shop I really want to get into blacksmithing. My problem I'm having is choosing between solid or propane forges. I've been leaning towards propane because it seems easier but I'm not sure. Looking at different designs I have no idea which one to choose. I look at the small firebrick forges and think that may not be sufficient but I have no clue. I've also really looked into solid fuel forges but I'm afraid I'd spend more time making the fire then forging, is that true?