-

Posts

20 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by rendoman

-

-

Thanks for the advice!

and for the name of the tool, I'm not an expert in english Language, and sometimes I have trouble finding the right tool. I think I will try to build a burnishing tool on my lathe, I got some aluminum and teflon scraps, with a radiused tool maybe I can do a nice job.

It's a good idea to make a rigid ribbon in the opening area, I think I will try in the next holster, not only to re-holster than to pull with thumb in order to facilitate the extraction (maybe my holster is too rigid and new)

I bought some more leather for a leg bag, with 2x3mm belt (5cm - 2" wide). I'm starting to build the belt, I post some picture

I bought also a couple of hollow punch bit, I discovered that mounted on a bench drill they are nice. Size 1mm. Maybe I used wrong glue, normal vinavil pressed with brass plates and transformers.

I posted even an aluminum tool found on a forum ( http://leatherworker.net/forum/topic/26604-edge-burnisher-for-dremels/ ) should I replicate something like this right?

-

-

Hi! you're right, 9x21 is close to a clock

. In Italy, usual 9x19mm is not permitted, but 9x21mm is fine for civil use, according to law...

. In Italy, usual 9x19mm is not permitted, but 9x21mm is fine for civil use, according to law...

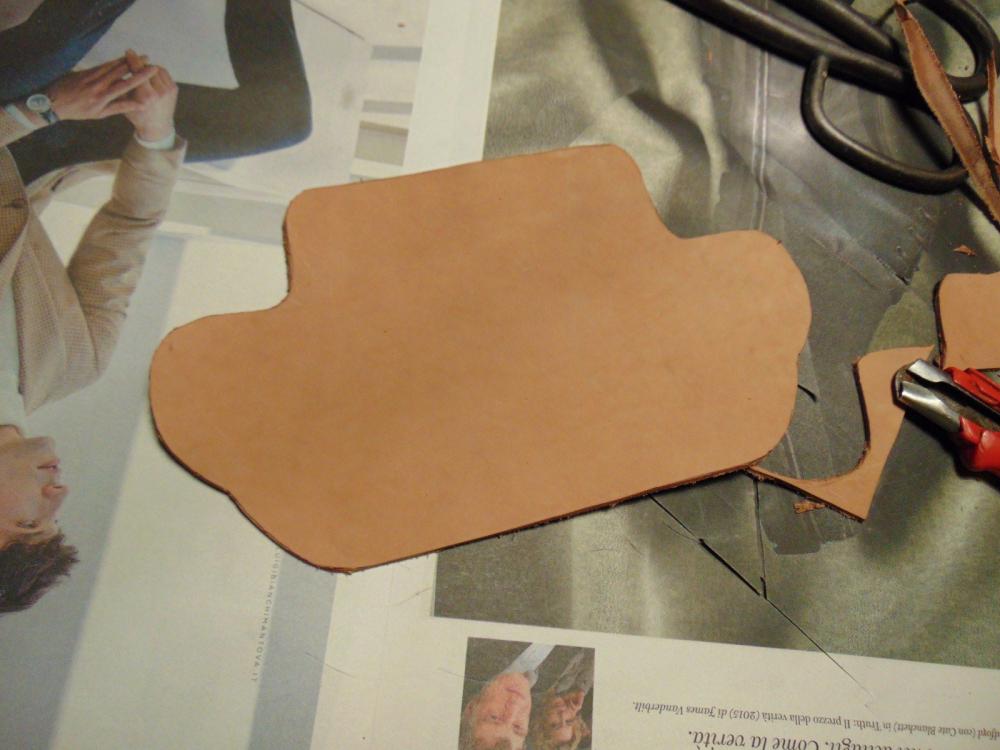

I finished sewing, I have to find a good hollow punch tool for waxed twine, I used 2mm drill bit, but holes are big, it's not a perfect job

Luckily the holster keeps the glock in perfect position, It's needed some strenght to pull out the pistol.

I will add a reinforcement in the top area, because 3mm leather is too soft , and trim the contour.

I used acetone dark brown dyeing and two hands of white shoe polish.I'm thinking the best way to finish edges

-

Hi all!

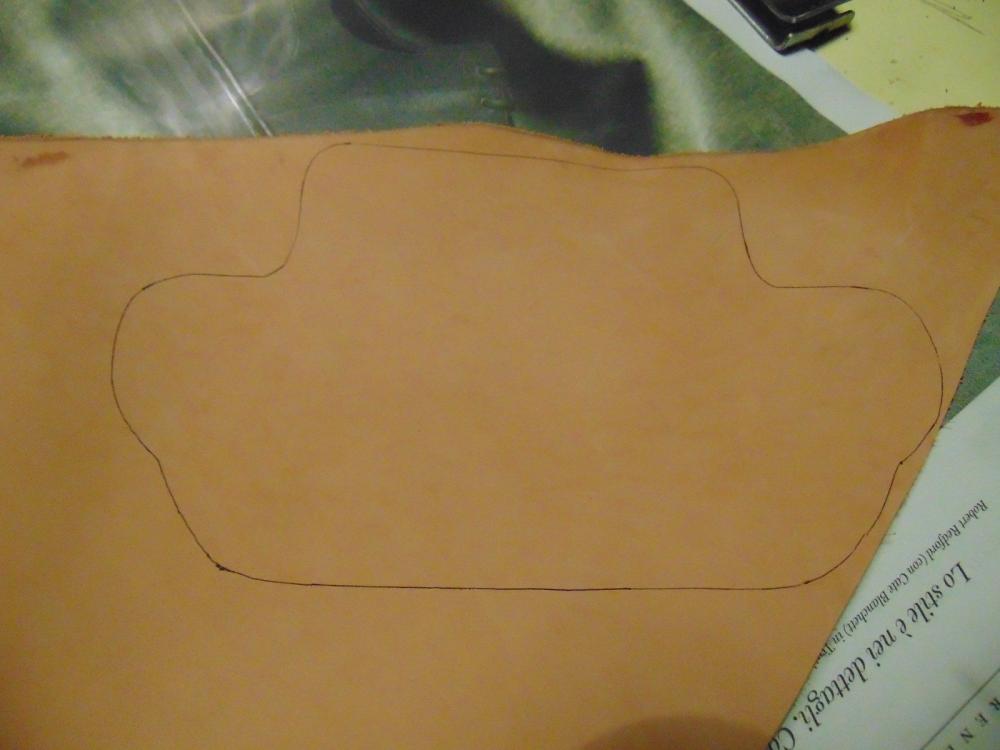

I'm trying to build a leather holster for my new little Glock 26 in 9x21 caliber.

I bought 3mm thick leather untreated, pretty soft, above all when wet. I followed your advice, I also bought a low priced tool for marking points ( unfortunately "pro" tool was 5 times the price ). I found a good pro dyeing, dark brown color maybe dissolved in acetone, the smell is pungent.

I've not found a jeans steel clip, I tried to make one from inox 2mm flat bar, hope It will be fine!

I post some picture of work in progress, advice are welcome!

Saluti

Stefano

-

Thanks for the link!

i'm beginning to understand now the concept of clinker and the use of sand or clay.

I'm thinking about tuyere, you're right, it will melt in few time with this high temperature in direct contact. Maybe a sort of exchangeable jet of tuyere can be good, set with a screw or a plug can be good, Could be better to change only a 10cm jet than the whole intake, or maybe use water cooling like video, or a water tank

more food for thought! I need to find fuel and try!

-

Hi!

Noob question: should I put some firebrick on the base and lateral in order to define area?

Today I cut a window on lateral side, maybe I should open another one on the other side. I added a front shield, maybe too high.

I finished the prehistoric valve, ugly but effective, from 0 to max air. I chose this style because it was easier to make, and above all it keeps a perfect cooling of the fan, not overloading.

I will add a front switch to start and stop fan and a "decent" cable

Thank you all for your advice!

-

Your advice are Always welcome!

You're right, I made something not correct in design, Tomorrow I will open a side window and cover the front

I never imagined that it would take so much coal (4-6") to run this forge, I'm so noob

thanks for advice!

-

-

Hi all!

Small update, not a perfect job, but at least nice to see

I make a small grill in stainless, don't remember if 304 or 316, for sausage and other bbq applications (yes I got no barbecue at home, that's my first!)

I found today this fan, it's ok, but I dont know if can be a nice blower, at first sight it has a strong air flow. I'm thinking about a mechanical valve in order to partialize flux, with exhaust... I got an hairdryer as second choice

Saluti

Stefano

-

Hi all!

Thanks to the advice given by many good members of this forum I decided to try a small side blast forge.

I found good metal scrap, a round part thick 1\2", good as base. I did air intake from square tube. A broken hairdryer will be the air source, the tube will be at 3" from base.

I built lateral bulkheads from 0,8mm steel, I folded with hammer the edges, not because I wanted to try hammer on anvil, rather because they were sharp.

I'm thinking about making them detechable, in order to facilitate cleaning and to use like barbecue

I post also my diy custard raspberry and strawberries tart

Saluti

Stefano -

I just finished my first apron, not a nice done job but at least usable.

I tried different lenght, I found that knee lenght is better for my use, very long apron is not so practical to use in kneeling position.

I decided to follow an advice to avoid pockets in the front, think about it, the molten iron sparks hurt! maybe it's better to not put pockets

I post some pictures of finished apron, I got garage in full disorder, please close one eye

I Drew a bad paper with some measure, i'm 1,85m x 90kg, maybe can be useful for someone

Saluti

Stefano

-

Hi!

I tried to do my best with anvil and hammer in order to make some buckles, but it's not easy! Aesthetics aside they are good.

I did some mistake with length and belts, that's my first time with a leather vest, without pattern it was a bit hard to take at first sight measures.

I finished with "stitching stamp" beacuse I started with this, in next works I will avoid to use.

I think I will do something else with leather, but always for "little things", for sure I will buy a stitching tools and the special Needles, they seems to me easier to use

I think Tomorrow I will make some pocket and glasss support.

Saluti

Stefano

-

Thank you all for your valuable advice!

Thanks wd&mlteach , As soon as it opens the leather shop (unfortunately 12 sept) I will buy this overstitching wheel, It's not easy to follow straight paths on soft skin. Your sheath and knife are really well made!

Thanks SLAG , I'm watching the Speedy Stitcher tool, it seems good to use, with wooden handle it can withstand pressure, it seems also serviceable to use, I have to search in local shop!

Thanks JHCC, I had thought to put a shelter in the pocket, but with fly ash and grind powder maybe it's better to put inside apron, I need to think about putting side pockets maybe, certainly more sheltered from dust

Thanks Charles R. Stevens, I will remember next time to not stitch across in high strain area, only sides. It's the first time I see this strange glovers needle, it seems a reamer with big head.

-

HI all!

I'm building a leather apron in order to preserve my clothes from sparks, welding and forge ( and maybe because I like this kind of clothing

)

)

I Used a beef leather about 2mm thick, hand sewn with waxed twine. I'm not so expericed with Needles, but I'm trying to do my best.

I will add some pocket with cover for small object, and a support for protective glasses

Saluti

Stefano

-

-

Thank you all!

I'm reading about different kind of forge, I think difference between models is related to fuel consumption right? I found some side blast english with water cooled injector, temperature should be really high inside! thanks for size and advice, I will start as soon as I will find steel and other components!

-

Ciao Patrick!

You feel confortable in Roma?

I'm searching for a brake drum in order to make my first little forge, but it's hard to find something, I tried in 4 different place today but nothing.... Maybe I have to change project

-

Thanks for the welcome!

Good eye! Anvil is 150kg ( 330 lbs), 90 cm long (35 " ) , I don't know the brand, when I went to take it there was also an other anvil, a little smaller, with a different shape. One striker and other side flat, like many I've seen on this forum, should I take both?

I'm reading about coal or solid fuel forge, I see brake drum type and flat with firebricks. I would prefer to not keep home a dedicated propane tank, I already have oxy-acetylene, maybe a small forge which can be mistaken for a barbecue is better! Yes, I love barbecue, but my dad no, He's contrary to put one at home, so a forge could be a good ninja start

-

Hi! I'm Stefano, from North Italy

I'm only a fan of Diy, few days ago I bought an anvil , and I discover this great forum searching for a forge. My goal is to make a billet of damascus for a short knife. I will search in the forum for some good info.

I got some old but good equipment: lathe, milling machine , table drill, grinders, benders and other things. I'm good at tig, electrode and oxy acetylene welding.

I like guns, above all western, revolvers and african rifles.

I also like motorbikes, I built 2 minibike just for fun, one with Piaggio engine tuned 70cc 2 strokes, and the second 250cc Tm racing engine, 2 stroke.

Another big passion is Hi-end type speakers and amplifiers. I'm also builiding a "Plasma Tweeter"

I post some images, they are worth a thousand words

Diy leather holster - Glock 26

in Gunsmithing, Muskets, Flintlocks etc

Posted

Thank you for the advice rockstar.esq!!