Chris Williams

-

Posts

273 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Chris Williams

-

-

What woods do you like to smoke peppers with?

-

That sounds like a plan! I've got many that need picking now. That will be the next batch.

-

I mix in powdered ghost peppers. I've got a few bushes that are around 5 years old that produce way more than I can eat, even when I sprinkle a little bit on everything savory. I dehydrate them and then put them into the single-purpose and well-labeled coffee grinder. There was an instance when someone in the household mixed up the grinders...

-

5 hours ago, BartW said:

people consider mayo one thing.

If you grow up being told thing 1 is a woozle, then you call that thing a woozle. It does not ever cross your mind that some other place has three kinds of woozle, and the variety that you are familiar with is a green woozle in that other place.

Ketchup wasn't quite the same in Tanzania, either. But it was certainly ketchup. We all have our ways, and it is just different.

Now, if someone visits you in Belgium and has an opportunity to experience multiple styles of mayonnaise and expand their palate, and yet still cannot recognize the difference... Well, not everyone is a connoisseur.

-

Wow. It saves bending over, I guess! I doubt the next horse resisted any.

-

It just means that they didn't cut up the horses.

-

I was previously aware of BÄRENJÄGER , now that you mention it, but such had passed beyond my remembrance.

I had to look it up again. "Bear Hunter," "Bear Trap," and "Male Bear," respectively.

-

Thanks Frosty! I must say that the mental image of someone trying to drink a bear was funny. Drinking a drunk bear got more interesting, but quite a bit safer.

-

What sort of friends do you have that drink bears? I guess you would have the lifting part handled well enough!

-

George, you have some familiarity with one method of powder production based on your background, even if you didn't even realize it. Direct ore reduction to sponge, followed by crushing, is one method. Separation is still required in this method.

-

3 hours ago, emtor said:

there exists a welding rod made from air hardening tool steel (Selectrode 1256) that do not require the base metal to be heated up. Hardness when untempered is 55-60 HRC.

That is an interesting rod. It is designed to weld air hardening tool steels, and the statement not to preheat applies to these steels. Your anvil most likely isn't an air hardening tool steel, bur rather is likely a high carbon steel. I expect that the anvil would require preheat to not crack. The rod itself forms tempered (good) Martensite when cooled, but your anvil will likely form untempered (Bad!) Martensite if you don't preheat and slow cool. Of course, if you do preheat, you may overtemper the Selectrode 1256 deposit and have an anvil top softer than you were expecting.

If you do end up trying it either way, please let us know how it turns out, what went well, and what you would do differently if you were going to do it again.

If it were me, I would use it a good, long while before ever considering anvil surgery.

-

How deeply is it hardened? It would be a shame to trade those dings (which look more like chisel marks than 'dings' from mis-strikes) for a smooth anvil that will be much easier to ding!

-

Materials has been a fun ride so far for me!

-

They'll work, but are consumables over time. How fast depends on your use.

-

Thank you. As both points 1 and 2 contribute to 1, these 3 are in order of importance as well!

-

I recently used the pole saw and cut several big dead branches out of our oak trees in the front yard. My wife wanted them gone before Isaias got here so they weren't a hazard in the wind, so I had the opportunity to make some charcoal.

I don't have a retort set up yet, but I was able to use a stainless steel HE washer drum to good effect. The holes in the side do such a good job of letting air in that the windward side was glowing red. I set it on an oak stump to avoid killing any grass, and I got around 2“ of charcoal from the top layer of the stump, too. The kids had fun helping me cut the branches to size, and with the good air flow, I had the whole pile burned down in a few hours. I soaked it with a hose to stop the burning.

It isn't an efficient way to make charcoal, but I can't complain about the speed. The "after" pic also included a little spilled anthracite, charcoal, and a few bits of forgotten wood from the driveway that I tossed in, but I had basically filled up the drum without that.

Long term, I would like to make a retort and get a better return on the wood. However, I had this setup ready to go and made a quantity of useful fuel without a big time investment. Hopefully someone sees possibility in their resources after seeing this.

-

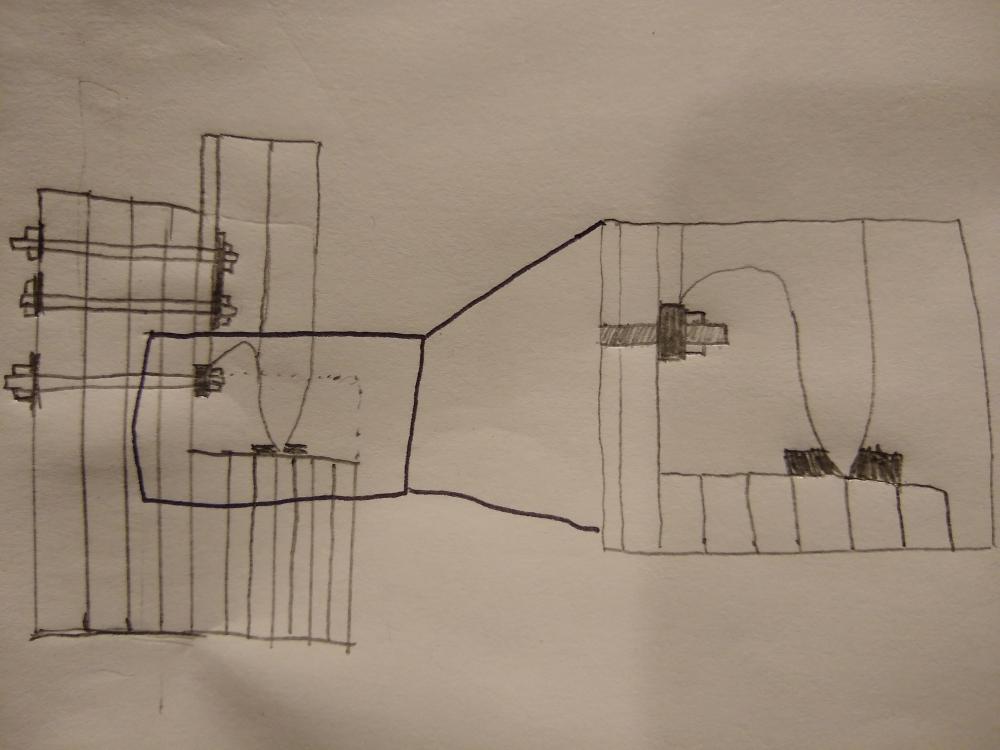

You can mount it vertically if you want. Make a stand like the recent one shown by Jealdi in the linked thread, and point the horn down. You just need to put a piece of plate steel with a counter-sunk hole for the horn tip to prevent it from sinking into the stand and splitting the wood. The wider/longer the footprint of the steel piece on the stand, the better. The extra layer hurts efficiency a little bit, but then you can use a vertical set up. I recommend caulk between the wood and steel. I didn't sketch it to scale, but I think the concept is clear enough. You can also bolt a bar under the end of the foot to minimize the tendency to compress the stand under the horn support.

Should you mount it vertically? I cannot say. I just thought of this way and haven't tried it. I just don't like the word "can't."

Either way, the most important thing is to get started and have fun learning to forge.

-

My wife loves cards against humanity.

It's funny, but I don't remember much about the speech therapy sessions except for my surroundings. "Round and round the rugged rock the ragged rascal ran" rings a bell, but I don't know whether it was from the therapy or not.

-

I've got the opposite problem. I couldn't tell a joke to save my life. I can say the most absurd thing, and everyone thinks that I am dead serious.

-

I had the speech therapy classes through elementary school. I was found out in my preschool years telling my parents that "There is glass in the grass!" during a family gathering. Parents, aunts, uncles, cousins, grandparents... noone could figure out what I was talking about. I eventually had them to follow me and pointed. I still don't know if it was the "L" or "R" (or both) that gave me trouble then, as I did not hear it any differently than I meant it. In fact, the only way I know that I still have remnants of the impediment is when I hear a recording of myself. To my ears, I "sound fine" while I am talking.

When I moved to Florida, all of my coworkers told me that I would be picking up a north Florida accent. It never took, but before I left that job eight years later, several of them had started pronouncing things more like me! I've been stubbornly resistant to such "improvement," without any noticeable effort on my part.

I did have a home inspector in Jacksonville, FL that pegged exactly where I was from within less than three sentences of introduction. Said he would know that accent anywhere, and named the closest "big" city. I took some accent/dialect identification tests later for fun, and it turns out that where I grew up in north Alabama has several interesting quirks that do make the language distinctive.

-

What are you eating for lunch? My teeth are inadequate to eat anything that I would be punching a hole with, square or otherwise!

-

Clothing, or accents... It's funny -- having a southern accent and very slight speech impediment, I always manage to exceed expectations! I wasn't quite as smart as Mr. Don Williams:

"But I was smarter than most and I could choose

Learned to talk like the man on the six o'clock news"

-

I appreciate you posting bellows rebuilds. I haven't come across a real one yet and enjoy looking at how they were put together.

-

You do have a point about stacking the old stuff on top. Whether the extra effort is worth it depends on how much attention she pays to it!

I've been wanting to find a plate like that to make a stake plate from. I've got some assorted cast iron chunks that I use for counter weights, and am glad to have them when they are needed.

Coronavirus 2020

in Everything Else

Posted

I had to search for Marquette wood, but haven't yet found what it is. Is that possibly an autocorrect from mesquite?

I generally use similar wood for the other things I smoke as what you describe. I use oak and pecan or hickory for pork also.

it was a spell checker induced typo