dps9999

Members-

Posts

103 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by dps9999

-

conflicting info on normalizing

dps9999 replied to dps9999's topic in Heat Treating Knives, Blades etc

perfect that is exactly what i needed to know thank you steve -

Hey guys i tried to post this in a topic i already had goin but after a few tries it wouldnt post thats why i am trying to see if i can make a new topic...i guess the site is acting funny again so i am cunfused on one thing when you normalize and do 3 heats how far do you let it cool between each heat i thought you heat till non magnetic let it cool slowly in "still air" until its room temp then repete twice that is what i did but now i have been told that your suposed to heat till non magnetic then take out of the forge just for a second or 2 until the color leaves and as soon as it turns black it goes back in forge and the last heat is the only one that cools to room temp.......wich is right what i did or only leting it cool to black between heats? maybe both? what do you guys do?

-

First try at a damascus blade

dps9999 replied to dps9999's topic in Heat Treating Knives, Blades etc

no i havent done any HT with this blade yet,, i keep hearing different opinions some say that normalizing is needed some say its not and then i hear that it causes ALOT of crap on the blade. i mean i know how to controll the atmosphere (as i did creating this blade) you think that will be enough. maybe brushing it when it comes out. i dont mind a lil i am going to have to deal with that no matter what but i just dont want it so bad i end up screwing up the shape tring to get it back off....also should i clean between each step...normalizing ,hardening, temper....this is the first time HTing in a propane forge -

First try at a damascus blade

dps9999 replied to dps9999's topic in Heat Treating Knives, Blades etc

ok steve your right ill admit when i am wrong i have been reading entirely to much i thought i posted this in bladesmiting/knife making .....sory didnt want to upset you can some one ansswer me one question...with a 1080/15n20 is it nesssacary to normalize 3 times before hardening i ask because i keep hearing that it will cause alot of scale and crap on the blade wich i dont want to deal with unless i have to as the blade is already shaped and a general primary bevel put on i dont want to have to sand or grind so heavy it messes that up -

First try at a damascus blade

dps9999 replied to dps9999's topic in Heat Treating Knives, Blades etc

ok honestly i have been reading soooo much i have only looked into this section abaout this -

First try at a damascus blade

dps9999 replied to dps9999's topic in Heat Treating Knives, Blades etc

thanks w pearson...........steve i dont see ANY sticky pins by you on the top of this forum page the only 2 that are there are "blacksmithng on history channel by frosty" and "new knife maker by rich hale" not saying its not on some other page but if you click knife making from the main page there is nothing by you or with a heat treating title ...now if wpearson is right with his link (havent click it yet but i would tend to think its right ) your post is not at the top of this page it is in another section of the forum wich honestly i didnt even bother looking at that section as another forum i was on a while ago had a section similar to that and it was all about people looking for knife making classes they can go to locally wich i already know there ar none near me so again.... quoting you "how about the sticky posted at the top of THIS page?".......not on this page -

First try at a damascus blade

dps9999 replied to dps9999's topic in Heat Treating Knives, Blades etc

ok ill have to look any way to see a list of these post's i did a search on his name and all sorts of stuff cam up not just from him -

First try at a damascus blade

dps9999 replied to dps9999's topic in Heat Treating Knives, Blades etc

thanks justin ...steve???what post?? -

First try at a damascus blade

dps9999 replied to dps9999's topic in Heat Treating Knives, Blades etc

oh also i am new to this so bear with me do i need to anneal or normalize the steel from where its at now before i harde or straight to harden.....is so does one need to be done right after other (same as above) -

hey guys so i got a 1080 and 15n20 blade i made and its time to heat treat...first how should i heat treat same as 1080 alone? also does the temper have to be done right away after hardening ....say i heat quench in canola oil tonight can i wait until tomorow to temper???THANKS

-

NEED HELP connecting tang braze/ braze weld/ weld ???

dps9999 replied to dps9999's topic in Knife Making

i have a stick welder (somewhere) have'nt used it in years didnt even think about that i have been using MIG/ Flux core most of the time i find my self using the flux core but for some reason i seem to be a lil better at MIG i dont know maybe cause there is no flux to get in the way unfortunatly i am confined to the flux core right now no gas for the mig. But anyway between the fact that my brazing skill is 0 to none and like i said before i didnt think about th HT where the braze might melt so i am just going to weld it best i can. i was woried about it lookin like crap but i think i am going to cut a brass plate for each side of the full (welded ) tang and in the brass plate i am going to cut finger grooves but i think i can also use it to hide the welds. i just gota figure out how to cut this brass plate to shape with out ruining it. the angle grinder isnt small enought to cut the details, i tried a diamond wheel on a dremmel didnt really work good and tin snips just bend the whole thing to pieces when i try and get in the tight spots. if any one got any ideas on that let me know. one way or another it will get done this is my first time forging a damascus knife i am determined one way or another it will be done -

NEED HELP connecting tang braze/ braze weld/ weld ???

dps9999 replied to dps9999's topic in Knife Making

alright thanks guys.. i did not even think of heat treating!!!! that would deffinitly melt the braze any way thanks for that one! also this whole thing started with me doubting being able to mig or flux core weld it with good strength with out the "bumpy bead" thats what i call it anyway some times my welds come out bumpy but not all the time i just welded 4 pieces of stock to make the outside of a picture frame ....i took my time and they came out good strength and looked real good. being somewhat new i guess i lack confidence with it some times so ill try worst case cut a lil off and try again. i have a 1/4 inch plate of mild steel, i have some 1080 amd 1084...i was going to use the mild cause i was told it works better for either brazing or flux core weld. i guess i could use either? by the way i have made a few blades but always made them with a tang as solid piece i never had to weld one on is the any type of joint i can make by cutting/grinding that will help the weld be as strong as possible for example some one told me for brazing make a "key" joint.... xxxxxxxxxx ooooooooooooooooo xxxxxxxxxxxxxxxxxxxxx oooooooo xxxxxxxxxx oooooooooooooooo thats would work well with brazing i think as the filler would get sucked into the joint but with weld staying pritty much on surface i dont think it would work good is there any othe type of joint i can make to help? thanks again guys oh forgot keep in mind it is a thin blade that might affect what i can do to manipulate a joint -

Hey guys so i have my first attempt at damascus or pattern steel billet and i want to make a knife. There is not enough of it to forge a tang so i was going to weld one on. So i know how to do MIG/Flux core weld. I am by no means a expert my welds dont look pretty but they do stick. I figured if i just weld it, it will be a lil bumpy (as most of my welds are) (again i taught my self and still learning). and grinding them real smooth taking away all that material with weaken the weld. On another site i was given advice to braze it on instead of welding. So i went and got a few different rods from home depot and also check the other little hard ware store by me and they had the same stuff as home depot ( i put links below for each type of rod i got, i figured that be better so you guys know exactly what i am talking about). Then i was told these rods are not strong enough and to use the 64% silver wire....i cant find (unless i buy $200 worth of it wich i do not have) i picked up 15% silver rods figured might be better than nothing (also a link below) on the companies site it says they are for copper to copper to . so now i am kinda stumped wich one of these rods should i use? Then i came across brazing vs braze welding page. What i get from that is brazing will get sucked down into the seam or crack but braze welding stays on the surface like regular welding well if that is the case can you braze weld ontop of a braze? and how do you control wether the filler gets sucked into the seam or not? Guys any advice would really be appreciated right now! oh also i do not have a oxy/acetylene torch I do have a oxy/map gas torch (wich is surprisingly strong i have played around brazing scrap and cutting steel i cut through 1/4 in thick steel plate no problem) THANKS GUYS! RODS I HAVE http://silfos.com/products/catalog/Sil-Fos-15-Silvaloy-15-28-Rods-p-150.html silver ones http://www.homedepot.com/p/Bernzomatic-WB5-Bronze-Flux-Coated-Brazing-and-Welding-Rods-334490/203710172 bernzomatic bronze http://www.homedepot.com/p/Lincoln-Electric-1-8-in-Flux-Coated-Brazing-Rods-1-lb-tube-KH515/202715833 lincoln electric bronze http://www.homedepot.com/p/Bernzomatic-AL3-Aluminum-Brazing-and-Welding-Rods-334491/203710179 bernzomatic aluminum

-

thors thanks that is what i was thinking but i want to make sure i get it right...appreciate it

-

WOW guys i can post again!!!!......i have been trying to ask this question for days now....so from what is said you can use this "goop" bees wax, turpentine, boiled linseed oil to create this black finish... but i am assuming you do this right outa the forge? no grinding or cleaning up or you do need to clean and grind ?

-

oh ok thats why i have a propane forge the only way i ever heard it referred as is atmosphere...to be honest i could probily use a lil refresher course like i said i read about that when i first started with this it hasnt been that long a little less that a year since i read anything about that but i have read / watched vids /ect...ALOT between now and then. I started slow about a year ago with this but about 4 months ago lets say i sudenly had ALOT more free time so i have read and done alot the past few months

-

ok thanks thomas i am definitely going to contact them tomorow that would be awesome i would love to go and watch i would feel greatfull just so see it done and if i actuly got to do something and had some one tell me what i do wrong/right that would be a HUGE plus. when i went to that fair when i found this guy putting on a demo my sister couldnt pull me away (she was my ride home so eventully i had to leave) watching and talking to this guy while he was doing his demo was very educational i loved it something crossed my mind are you guys talking about neutral or a reducing atmosphere? or is it something different? i have read and learned a little are you talking about the flame burning all in or partly out and mix of O2? where ya tell by looking at flame leaving the forge? i have read some about that just never heard it as "heat" always atmosphere and correct me if i am wrong but isnt it one or the other neutral or reducing? not both or "neutral to reducing" its been a while that was one of the first things some one online suggested i read up on

-

charlotte "neutral to reducing welding heat"????????? Thomas... no i wish man i have looked the closest i came was when me and family go to this county fair its about 30 mins north of me they had a blacksmith demo i asked the guy he seemed somewhat willing but i found out he is another hour up so it would take me like a hour and half to get up there. Dont get me wrong if i could i would in a heartbeat but i dont have a car right now so asking some one to bring me all the way up there and hang around for a few hours till i am done is not going to happen. i got his card to incase the oppertunity comes up tho......the thing that gets me is the first 2 times welding and drawing out there was absolutly no problem the 3rd time it went from the mass of my whole hand (maybe wrist too) to the mass and size slightly bigger than my finger the only thing i did different was etching it before that was my first thought but i cleaned it pritty good even used baking soda. i dont know what i did.....

-

posted new topic about the above mention to damascus i tried would let me post it here...lets see if this works

-

Ok i tried to post this on another topic but it wouldnt let me i tried a bunch of times so i hope this works its off topic from that thread anyway........... ...So I am in the process of making a Damascus or pattern welded billet (first time doing this). I took 7 layers of 1080 and 15n20 stacked and welded on a handle and forge welded the stack…then drew it out cut to 3 pieces, stacked and welded again, drew it out again. Now at this point some one told me etching might be a good idea just to see what I got (I figured I would have nothing as all I have done is added more layers and compressed no twisting or grinding yet) so I etched and it was all dark grey except 2 lil blobs on one end a little smaller than a dime. So I washed it off cut and welded again and forged it into a rod like shape twisted, cut again and stacked. Today I will forge weld for the last time and forge to a blade. So ok everything’s good right? NO since I etched it between the last forge weld I did and draw out I lost A LOT of mass,…..NO exaggeration this billet was big enough for 3 pocket sized blades now it’s only big enough for one small one. I lost probilly 60% of the size where the XXXXX did it go? I thought the acid (I used ferric chloride from radio shack) because it didn’t happen before that but I cleaned it real good soap and water and even baking soda (I was told baking soda neutralizes the acid) I just don’t understand this at all. I wouldn’t be mad if I made a mistake (obviously I screwed up somewhere) IF I learned something but I have no clue as to what went on here . Does any one have any thoughts on this? Did this ever happen to any of you? watch your language this is a G rated, family friendly forum

-

i have tried to put up a post with a few questions it wont go up. Am i missing something?...its a lil long ill try again in a little while..lets see if this goes up Ok guys I tried to put this post up twice last night and it didn’t go up. I don’t know what I did and I should have copy and paste but I didn’t so here it goes again….. Dogsoldat… that is a cool little leaf I might try and use that on the frame…. I have decide to first make her a picture frame just because as I said before I have a picture of her 1 year old son from when we went to the intrepid museum (WW2 aircraft carrier) it’s a pic of him sitting in the captain’s chair. I was supposed to print this pic but had no ink for the printer at the time and I think she forgot about it now so I think she will be happy to have the picture and the frame. Now I have 2 weeks to do this wich I suspect will be more than enough time so if I have the time I am going to try a rose also. If I have a hard time with it then at the very least it’s a learning experience and I still got the frame to give her. the pics above was part of a question about this "goop" is that what was used to finish them or the pics dogsoldat posted....how are they finished? Ok also I have a question that is off topic I don’t know how you guys do things on this forum should I post here or make a new thread? I will just post it here for now…..So I am in the process of making a Damascus or pattern welded billet (first time doing this).

-

Ok that quote was from a previous post can any one explain this to me looking on the web all the decoration stuff (or most of it anyway) has a black finish to it. Is this paint ot something similar? i would assume after heating and working so much you would have to grind it and clean it but that would make it a silver shiny color right? How do you acomplish this black finish or if you do grind it to silver how to you make it rust proof?

-

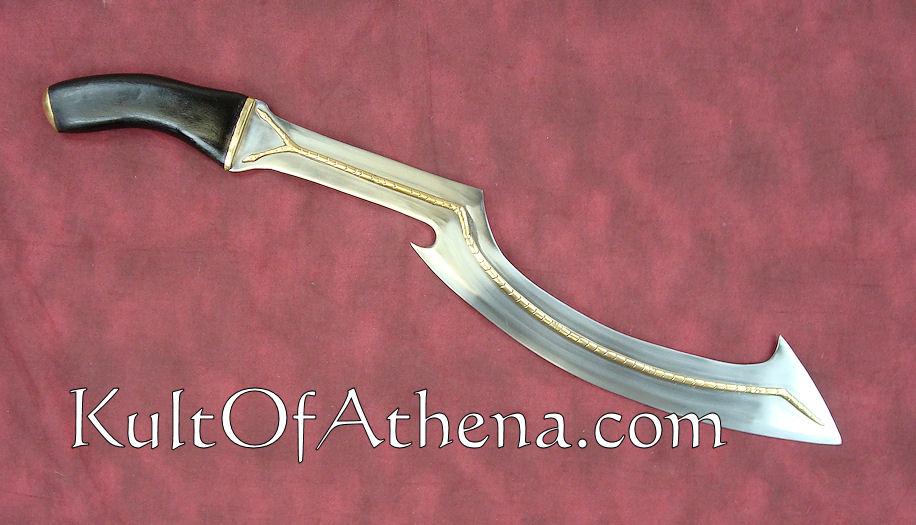

First i had no ideas now too many maybe i shouldn't have asked...LOL Just Kidding. I appreciate every ones input you guys really helped me out on this one and yes glen i will be sure to take and post pics of what i end up doing. Rashelle, thanks good to hear a womans input on this topic.I am going to search for Brian Brazeal or Alec Steele on you tube and see what i can find. Glen i am going to look up russian rose in a few minutes also. Bad creek thanks i have mad a couple pins with these brass rods i have so i should be able to do that. I do have a question tho i have posted to pics (pics taken from a site that sells them but i have the exact same sword) So ya see this brass strip down the middle can any one take a guess on how it is attached. It is on both sides of the blade. Its definitely done by had as you can see VERY small little imperfections. It seams like there might be strategically placed small holes where it is somehow fastened together with the strip on the other side. I only assume this cause there are a couple spots where if you hold it up to the light you can just barely see light where the brass strip has lifted from the blade piece and both strips on either side come back to the blade and each other at the same points. This would be a ideal way to attach the brass rod to a frame or something similar but i think it might be a lil to complicated for me right now. I cant even figure out exactly how it is done. Anyone got any ideas. Also Ausfire.... i cant even see the pic you posted. when you get time try again. THANKS again everyone!

-

Thanks guys really awesome ideas i am going to have to think about this one tonight. First i was reading the pic frame would be good because (Oh by the way i live in NY about a hour north of NY City) anyway me and her took a trip to the intrepid muesem (it is basically a WW2 aircraft carrier docked on the west side of Manhattan its cool planes on the flight deck hanger deck has all sorts of military equipment and exhibits and now they have one of the space shuttles that was retired....cool place) But her phone camera broke and i have a picture of her son sitting in the captain's chair on the bridge of the ship. i was supposed to print this pic out but i didnt have ink in the printer and now i think she forgot about it. So that could be a good lil combo gift. Where she works hmmmm well it started as this little strickly spanish place i was actually suprised they hired her she is the only white girl in the place kinda funny. This place has expanded it serves all types of food and also has a active bar. Not the type of bar where you find 500 college kids every night but does have decent clientel as so with the resturaunt. i feel she would like a necklace or frame more than a bottle opener tho. Frosty the idea of taking apart a flower is geious! HA something soo simple never would of crossed my mind. Also as you all said every woman likes a necklace. I think even with the torn apart flower it would still be harder than a frame or cross necklace. maybe ill take apart a flower just to get a idea of what it will take (even if its not in time to give to her it does look like a huge learning experience). I got some thinking to do tonight now guys thanks again. One question tho... ok lets say the frame for example (could apply to anything tho) Say i take some square stock and twist bend to shape to make the frame. I have some brass rods with nothing to do with them. say i flattened out parts of the frame and wanted to attach them should i just use some high strength epoxy or is there a easy enough way to do it with out the epoxy (keep in mind i have never "physically" attached something like that before except forge welding a damascus billet something like that would distort the brass rod to much. Also if i were to grind down the metal at the end to make the surface consistent and no burnt slag residue. this would make the surface shiny and silver right (this is what i did with the brackets i made to hold my swords and i put "meuseam wax" on it so it wont rust same thing i do with carbon steel swords) ok 2 things i have seen pics online of decrotive stuff with a black finish to it now silver how does that happen wouldnt it also turn silver when grinded or sanded but it looks better than straight out of the forge? Lastly if you grind it down and polish so its nice and shiny how can you rust proof it? i wouldnt want to put that wax on a necklace for example cause it would rub off and she would constantly have to reapply the wax and thats no good and i wouldnt want to paint it. Ok thats it LOL i know its alot... answer what ya can when ya can and if ya can it will be appreciated............going to think about these options really guys i was stumped and you all had great idea's! thanks again HMMM spanky i know that they are napkin rings but the pic made me think braclet! Wow you guys are great a lil more than a hour ago i was stumped searching the web for a long time with no good ideas so i asked you guys its a hour later and now i have too many ideas! awsome just goes the prove this is a awsome site with a even better collection of people

-

Hey guys i am trying to come up with a present that i could make for my friend. I want it to be something practical that might have a use to it if not then something a lil different (basicly not something like a basic plain heart unless it is unique in some way as a decoration. I thought of making a flower or a rose so i looked online for any tips or advice on doing that and everything i found like a 7 petal extremely detailed rose is deffinitly above my skill level. I am kinda stumped i thought maybe something she could use at work (she is a waitress) or she has a baby that just turned 1 a few days ago so i thought maybe a decoration or something to help on that front. Still drew a blank.This girl is a very important person, we are not a couple or anything (not that i would mind but both of us got to much going on for that now) I know she would appreciate something i could make more than going and buying something. However as i said my skills are not great i deffinitly qualify as a beginer i have made a couple stock removal knives 1 forged knife i am in the middle of creating a damascus billet for a knife blade. I also have made some custom decrotive brackets to hold some of my sword colection to that wall. I am generally pritty good with my hands but the blacksmithing skill is still very new to me. I would really appreciate any idea you guys might have....i still think a flower or something along those lines would be great but would be VERY helpfull to have a good description or a template of sorts to work from but as i said everything i found seems a lil much for me. If i had a month and alot of steel to have materials and time to make many mistakes i could probilly do it but would be a challenge even if i had alot of time....thanks to any one who many have any ideas!