JamesH

Members-

Posts

27 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by JamesH

-

I tried a search for something similar and failed, so appologies if this is an old hash. The one thing that people seem to sat say is that it they were somehow instantly hooked. Some amazing history in peoples answers though, especially you smoothbore!

-

I sure hope not, its just so inconsistent. It never cut out once in all the times i've used the angle grinder, drills or saws. I think it's just a test and see thing but im praying all the same

-

Started some agency work a few years ago in one of the big chain stores, shaved and showered at 5am and around noon the same day my new manager told me I needed to make sure I shave to keep in line with store policy on acceptable grooming. I didn't last 2 weeks.....

-

Found today when visiting relatives, I knew grandad was a bit of a horder before he died (well over a decade ago) and nan had cleared a lot of his "junk" when they took down his old shed but she kept a set of his old draws with misc tools she didnt understand. But the real gems are a set of well loved punches, a hardy tool and what mustr be a very uncomfortable to use fuller! other than that some old forged gate hinges, calipers and a nice amount of tool and misc steel!

-

Title said it all. Just curious to know what brought all of you into Blacksmithing? family history? hobby? Its a question I almost always ask when I meet a Smith, and the answers are always worth hearing! I'll start; I first got into the idea of Smithing when after working dead end jobs i decided that i needed to do something more creative and with my hands. It came down to woodwork or metalwork, and then after talking to my grandparents and hearing them tell stories of the horses, the forge and fire, the incredible things they watched their father make and how people came to know him just couldn't get out of my head. I watched a few videos and then went to a festival and did a taster and didnt stop dreaming about making something for 2 weeks. 8 months, lots of wood,sweat and nails on here today and im almost ready to switch on my own forge and start my own journey, just one powercable away... So then! whats your story?

-

we have neither Air Con nor any fans really, ID is not exadgerating when he said 4 days. Even the heating is off at the moment pending an upgrade. Smoggy I couldn't agree more, seeing it all in action and knowing its so close now I just can't wait! I think i'll probably keep it (the forge) for now, and when i've had a chance to try it if its not too my taste I can always sell and would most deffinately buy and recomend one of Iron Dwarfs forges, especially now that i've seen one after a few hours use. Worked a lot better than the ones i've seen and used at the few demo's i've been too. A hand crank would probably work frosty, but I think im going to take up ID's offer of making me a 50m cable and sockets, the othher issues will just have to wait untill next summer when i'm more prepared to afford or tackle them.

-

that was some amazing identification skills! Sadly though It's not limited to the kettle, also happens to the oven, pond pump....any socket really though it seems worse in summer. And I'm not opposed to extension cords, but given the season using multiple is a flat no and if there's simpler solutions...thanks Forthe help! Irondwarf was asking what motor it was and I was at a los

-

Its more for the curious soul in me, I just like the thought of all the other people through the years who might of used it. Maybe it could of been one of my great grandparents? One of them had a forge just a couple of miles from where we found this one and apparently in his day was quite a known man! Sometimes though I do think i over romanticise thinggs.....

-

-

Very excited to meet you and learn something! Thank you all for everything so far too, got a lot of options to research think about

-

does anyone recognise anything? i've been trying to do some online searching but nothing distinct. The feet tend to be wrong for a lot of the descriptions im seeing.

-

I see no labels, stamps, stickers, plates or anything more than just the dial on the blower. It appears to be the original part and has a 13A fuse. and smoggy i know exactly what you mean. I started with 4 poles in the ground with a tarp over and now i've ended up with 4 walls, gaps for ventilation, a solid oak table to use as a bench and the upcoming issue of; "which of my friends wants to help me move just a couple of heavy items down this very long garden?" Just nearly lost a leg trying to lay the anvil on its side to see the base!

-

Pictures are here! I can make out 3 numbers on one side, which are; "2 2 19" and on the other I can just make out a circle nearer the top. but it's very hard to see in person let alone on camera. Frosty using daylight and shinging it at an angle worked a treat! Also took photo of the base, feet, and different angles.

-

I'm hoping too Thanks smoggy and dwarf. Sorry to hear your struggling too, its a shame something that only a couple generations ago was almost a 1 in 5 job is now so awkward to even begin!

-

This is another ideal solution. Gen is something i'd end up buying downline anyway I think so I can jusitfy this more expense-wise and i'd not even realised I could use batteries until this thread! Is their a guide on here somewhere for setting up whatever connections i'd need?

-

g Ill take tomorrow, this would be ideal. Whoever did the extension has bodged it on the "ring" somewhere, The price for cable is £100, the cost of the electrician to sort the power is a mystery and for sockets alone would be atleast another £100+ which is more than i spent to build the workshop! so thats something id love to avoid when we might be moving in a couple years anyway, we can get the same sockets here but again its the source and the expense. Double post due to site errors, so replied seperately to save deleting a post.

-

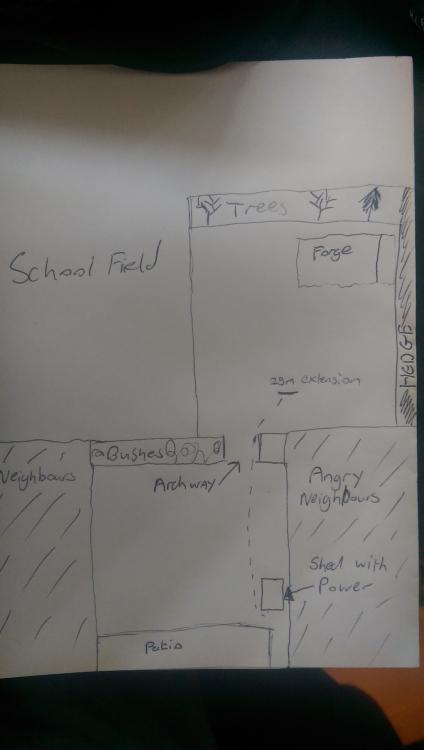

Okay, so in the picture attached the "Patio" is the rear of our property. The dotted line shows the path the extension cord goes. The garden layout is due to the previous owners buying the bottom half of the angry neighbours garden, the school field is used daily by the students and school so health and safety says nothing at all near there. The archway is a narrow trellised opening that leads to the "second garden" and has a stone path leading through. The map also does not show things like the rockery, the stone slabs, the actual gradients and way the space is being used but basically to lay power i'd have to run a cable from the shed shown, along angry neighbours wall, either through a fence and set of bushes or the archway where it would have to imediately head right towards the hedges, and then along to the forge to prevent the cable from being buried where people do gardening, cut the grass or couldnt accidently damage it. 35m was as estimate on my part, but as the 25m stops where ilustrated when almost heading as the crow flies then it may actually be closer to 50m when the turns are taken into account. The power draw is around 200 volts if i recall right? This when ready will be used almost daily, for hours at a time and for woodwork as well as metal. The extension cord idea was what i originally hoped to do untill it came to trying and the distance became all to apparent....

-

we have extension cords, but it takes two too reach the shop and that doesnt help the bad house circuitry. But if theres rain it shuts down the whole thing and the layout of the garden makes that very impracticle. Pluss now its winter its raining almost every other day. I'll draw out a map of the garden to help ilustrate the problem.

-

Sadly this one requires the electricity, thats why it's such an issue right now. It has a blower and everything built on the back, unless you meant to remove the electrical element and attach a bellows that way? i'm sorry if im confusing you or not being descriptive enough, the learning curve is feeling so vertical recently its begun its own scrollwork. So you recomend I keep this one for now, and simply get another one rather than sell or trade into something else?

-

Thank you! errored twice so i'll try keep it short this time. Its the price of armoured cable per meter, pluss i'd have to dig up a 35ish meter trench to lay it. Then theres the cost of getting a professional who might understand why we cant always use the kettle without a power cut to come and make sure its all wired in properly. The forge is almost new and i saw the receipt when I bought it and im very glad it was "second hand" Sadly due to all the issues in starting up I've no idea how to even use it... EDIT: As for bellows and alternative airflows i'm vastly inexperienced and a lot of the pros and cons are completely lost on me. Its getting demoralising now but i'd kill for someone to just walk in and talk me through it all.

-

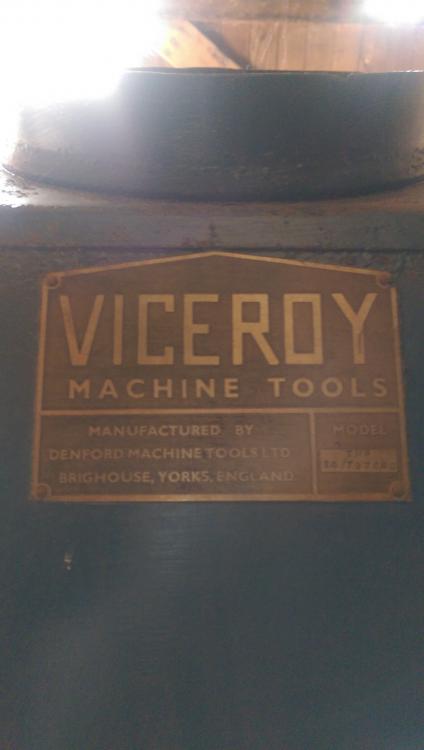

Hi everyone, i'm here to ask you all for yet more advice. When i bought my anvil, vise and tools the seller talked me into taking his forge too, which at the time seemed like a good idea. Now the problem is that i've had to buy materials for and build a lean-to/workshop type structure down the garden, to eventually work in, and generally make sure its suitable for what I intend to do. i've spent months working on this trying to get it all ready to use before winter and my personal deadlines keep being missed and its disheartening. Now the forge I got is a beautifull thing, however i've never even had the chance to light it and after the cost of building and aquiring everything to actually start swinging i've now ran into the issue of electricity to power the blower on the forge and it's starting to get demoralising. The cost of laying a cable and getting power would be madness and due to recent circumstances money has suddenly became a very precious comodity. What i'd like to know is if you all think I would be better served selling or trading my current forge for somthing smaller and simpler to get me started, and worry about paying for such luxurys as a blower and power points when i'm skilled enough for that to be more of an issue and can hopefully make my forgings pay for itself. This is very much currently a hobby too, though it is my hope than in a couple of years it could be a side-business. I'll attach photos, and thank you all again for everything. I'll also add coke or smokeless fuel is a virtual must. The neighbours are very particular and while the noise and hammering is fine if they think smoke could get to their lillys there will be letters to the local council etc. This is in the West Midlands, UK

-

i'm stuck indoors waiting on repair people for now, but later i'll give it a good cleaning and report back. Not sure on the taper myself frosty! Could be an un-even stump or maybe the lights caught one of the cold forged horseshoe lines

-

Thank you both very much. Wire brush I can do, the paint came with the purchase. I'd love to know the history and will take more pictures as soon as i can (stored at seperate address) the flour and babypowder is something i'd never thought of! thanks again!

-

anyone please?

-

Title said it all, just lookign to learn something before I start using it. Bought off a farmer who used to do some forgework but then left it to their farrier, you can see on the face the distinct imprints in places from the shoes. This is in Warwickshire, England if that help the identification, and by my estimates weighs easilly over 100kg. It has been painted black but theres also evidence of blue too. Very new to this so any advice is very welcome The photo with the ruler is just the square face. Including the horn it extended past the ruler.