Seek

Members-

Posts

67 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Seek

-

Hi everyone, I have been quiet for some time, but have learned a lot in the mean time, I am following a beginners course from a real smith, which is very helpfull. Now I am thinking about making something that I can actually use. I have a small cabinet in the works which needs some nice period looking hinges, the period being the 17th century, Somewhat like this: I have been watching a show from Colonial Williamsburg, so I actually have an idea how to make them. But I have a question about the choice of material. Wrought iron would be perfect, but I don't have any, so, normal sheet steel it is going to be. I need to do some forge welding. And that is an art I haven't quite mastered yet. This hinge is very small, so it needs to be made from thin material. Would it be wise to start with 2mm thin steel plate (that is about 5/64"). Is it very difficult to forge weld such thin material? I will practice on thicker stuff first.

-

Testing a forge weld, what to look for?

Seek replied to Seek's topic in Blacksmithing, General Discussion

Thanks Joe. And that is a very nice piece you made. It'll be next week before I can do any smithing but I sure will give it another try. -

The design will be very simple. Just a round tube 10" diameter with 2" insulation. And a 3/4" venturi burner. They also have a blanket for 1430 degrees but it is a lot more expendive.

-

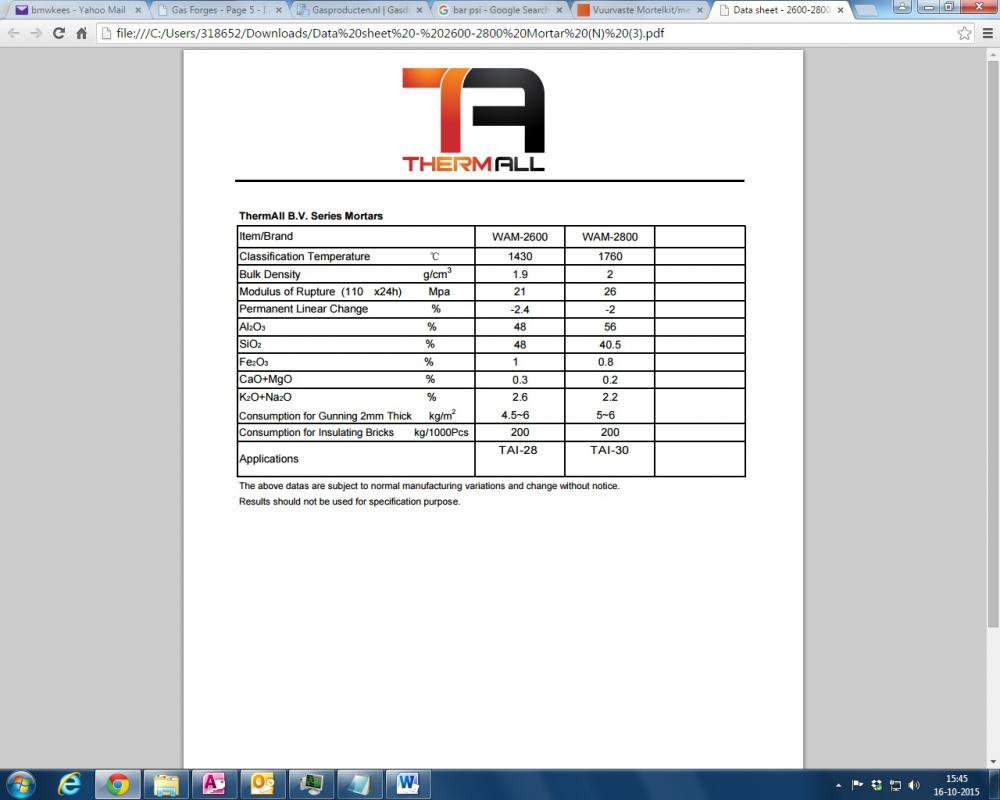

I am looking to make a small gas forge. All the articles on the internet are very helpfull, but they mostly specify American materials that are unavailable overhere. I am planning to use a ceramic blanket, valid up to 1260 degrees, about 2"think. Then coat that with a mortar like this one. Would that be good enough? What is this stuff really? Would it help to give it another coating with ICT-100 kind of material?

-

Testing a forge weld, what to look for?

Seek replied to Seek's topic in Blacksmithing, General Discussion

Yes that video from Mark Aspery is very enlightening. I am going to give it another try, but have to wait for when I have time again. All the tips above give me plenty of things to experiment. -

Testing a forge weld, what to look for?

Seek replied to Seek's topic in Blacksmithing, General Discussion

My first real goal is making some hinges for a couple of cabinets I want to make. So I really have to do more practice. About all the tips posted above: No I didn't think of any of these. So, thanks for summing them up again. -

Testing a forge weld, what to look for?

Seek replied to Seek's topic in Blacksmithing, General Discussion

Good to know I didn't succeed on the first try. But itwas fun to give it a go. Next month I am enlisted in a beginners course. hopefully there will be time for this too. -

Today I tried a bit of forge welding too. Just a test and nothing complicated. I bend over the last bit of some flat bar, smashed it flat and then welded it . First cleaned it, then heated it up in my charcoal fire. I used a bit of borax, heated more till yellow heat and tested with a pointed end of another piece of steel if it was sticky. Heated a little more and smashed it on the anvil. Repeated for good measure and then tried to pry it apart in the vise. Now I need a bit of help. Did this weld at all? What am I looking at? The nice gray areas, where they welded? Is it always possible to pry apart a forge weld?

-

Thanks for the pictures and the comments. It's all quite subtle I see, but I might try a bit of a bulge in the middle and a bit of an idea of a knob at the end. Keeping the sides flat.

-

My few hammers all have very straight handles. I suspect this doesn't help for the fatigue in my hand. So I would like to shape them a bit. But I really have no idea how a decent handle should look like. Do any of you have some images i could work from?

-

Nail header failures, but I'm not quitting.

Seek replied to Daswulf's topic in Tools, general discussion

That's a succes allready! -

The fun of a laminated chisel is in the ability to pair a simple high carbon steel at rather high hardness with a softer backing, toughness and hardness in one. That allows you to sharpen the edge to scary sharp heights, it allows you to retain the use of old fashioned oilstones and it shortens the sharpening time, because most of the steel is pretty soft, only a small bit is very hard. These are the kind of things woodworkers can argue about ad nauseum. In handtool woodworking everything is about sharpness, and easy and quick ways to restore that sharpness. Edge durability is of secondairy concern (not unimportant, but not as important as you might think).

-

Thanks for the answers. Indeed the Japanese smiths still make laminated chisels. I think in the western world this process is very rare nowadays, while it was very common at least until the start of the 20th century. Planeblades likewise.

-

Dies this carbon migration also happen in laminated tools, like antique woodworking chisels and axes? They were usually made from wrought iron with a high carbon bit forge welded on the end. Of course that was just one time welding, but I wonder if it is an issue with these too?

-

Thanks. I've got some experimentation to do. That'll be next weekend though.

-

I am not familiar with coffee cans. A round tin I suppose, what size are they in the US? How about closing in the fire bricks, so the area in between is smaller?

-

Here is a picture of my forge while it is still empty. Air comes from below through a rather thick pipe, a good 2" inside diameter. The blower is plenty strong enough and I run it on half power with a big old rheostat. The fire bricks are new (as you can see) and helped a lot to build a higher fire today. The brake rotor is only 4 cm deep, pretty shallow. And here is also a video with the setup running on full power. This is during the short period that everything is perfect. I start with a lot of fresh black charcoal. Then rather quickly the amount of fuel diminishes until I am back to a very shallow fire again. But i can make steel hot as you see. At one point I even had a little bit of sparkling (luckily on an unimportant piece). I would apreciate any tips to enhance the efficiency. Keep in mind that I live in a rather crowded area and do this at the back of the garden! Today I used close to 10 kg of charcoal to make some tongs. IMG_2191.MOV Here is the link to the youtube video: Forge fire.

-

Tomorrow I hope to have some time for the hobby again (Mondays of are great, the neighbourhood is quite deserted so i don't bother too many people). I will make some pictures. I do like burnig the charcoal and it is easilly available. But my current setup isn't deep enough so I struggle to get high temperature. I got some fire bricks so I can pile it up higher. Hopefully that helps to get a hotter fire too.

-

This is probably a total noob question, but I searched around for an answer and didn't really find it. So, please forgive if this has been discussed a 1000 times. Until now I used charcoal (been forging 3 days now, in 3 weeks), I like how it burns but I run through the home depot sacs at astonishing speed. So I looked where to get coal, and it seems that an online webshop sells this stuff overhere especially for smithing purposes. But they also sell coke. The price is only marginally higher and they say that it cuts down a lot on the smoke produced. Because I work in a very urban environment, that would be a major plus. I know that you can make your own coke on the edge of your fire, but if it is availbale ready made, why not? Is this coke stuff really good?

-

Thanks for the tip. But i don't think Molasses is a very regular staple overhere in Europe. I wouldn't know where to find it. But never mind. I have allready decided that the rusty vise is a lost case while I am enjoying the "new" one, pictured above, I only lost about 10 euros and it gives me a copious amount of scrap steel.

-

There certainly is no shortage of post vises yet. At any day I can find plenty of them on the Internet second hand lists. The first one I bought was really cheap but I failed to detect that the screw had rusted solidly together. Even after days of penetrating oil and applying heat it wouldn't budge. I think that one was fished out of the water.

-

i understand your concern. That would be very unfortunate indeed. According to the seller his grandfather was the bailiff of the church, also in charge of the graveyard, and he actually USED the vise. But I have no way to confirm his story. If and when this really has been a fraud, then I can only hope the blacksmith aproves of the vise being used again.

-

Ha ha! From a deceased blacksmith you mean...

-

Here's a picture of my vise. Funny, it was owned by a church. It had been standing on a graveyard for ages. No idea what it was used for, and I don't think I want to know! It has been outside, but the rust was only superficial, so I guess it's made of wrought iron. I used some Hamerite to smarten it up a little bit.

-

Searching around a bit I found some Peddinghaus hammers that aren't very expensive either. Just a pitty I must order them online, meaning extra postage. But probably a better idea then buying unknown cheap steel. In the mean time I have a very decent hammer, but I would like something a bit heavier too.