-

Posts

9,749 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Daswulf

-

-

Mine as well. We can only hope we inspired. Pretty sure you will be fondly thought of. Anyway lets live while we live.

ζούμε όσο ζούμε -

George, absolutely no shame in who you were,are or what you did. You experienced a great deal of things. From the man I know it made you a great person. I appreciate all the knowledge and friendship you share here.

-

-

Those pictures have a lot of meaning insight and put things only mentioned into context George. Thank you for sharing. Really brings home what you guys dealt with if only a fraction of the times you had the leisure to even take a photo.

-

Thanks Frosty. Sure would be nice to see the hands on trades back in schools. Funny the "Librarian/career counseler " that invited me there put money in my hand about halfway through. I insisted I didn't want/need it and that I was there to inspire and educate and that I wasn't out anything being there. (Using a vacation day from work. Have enough to spare.) But she insisted. Anyway, all trades needed or led back to blacksmithing. Like I said, if one kid was inspired that is payment enough. Most kids that even payed attention had no idea how simple it was to start.

-

Just wanted to say that the fair went well. It was trickles of students out to the area. The rain did set things back a little but with it off and on didnt stop anything. There were a few pretty curious but most reminded me of the trivial things we thought were important back at that time.

I was glad to share what I could with those that had questions or seemed remotely interested.

Didn't even get asked if I could make a sword. Lol.

The teachers and administration were happy and impressed and I was openly invited back if when they do it again. This was their first go at it.

-

Sorry to hear you lost your friend. Nice marker and sentiment of loving memory for him.

-

Looks great. Well done and I'm sure your dad will love it.

-

14 hours ago, Kenny O said:

validation that this is just an ornament

Exactly. This is what we call an ASO. (Anvil shaped object) might look like one but is Far worse than just a solid chunk of steel to use as one.

A lot of times the vise section is missing and people try to sell them as anvils.

It is neat but not so useful.

-

That is a beautiful anvil. That would be a very good price here in my area of the USA. No doubt a great tool that will pay for itself over time.

-

Stick with what you want to and with what you are comfortable making.

Sometimes suggestions on what someone wants and will be purchasing is fine if it clicks with me and I know I am ready and capable. Other times I've turned down work I knew I wouldn't have time for or the right materials or even thought process to make.

I much prefer to make things that I like and come natural to me then offer them up. It keeps it fun for me and I never had a problem selling what I make. If this was my main living things might be different.

-

Deffinately Frosty. I plan to do so and be generous with it.

-

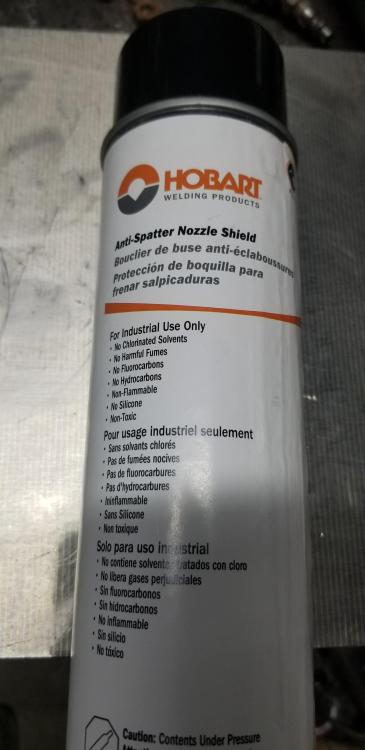

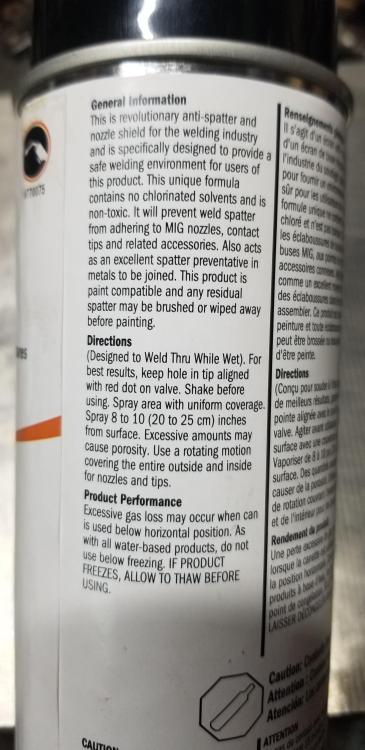

Here is one brand I use. (Depends where I am when I need some. Most all act the same.

No matter what you are painting it should be degreased, dried, maybe scuffed and warmed/maintained at/to the recommended usage temp.

Silicones are BAD for anything you might be painting. If a silicone was used on a part you want to paint or clear you should degrease, dry heat and repeat ten times, spin counterclockwise in a pentagram circle 3times then pray to your God or Gods of choice and then hope for the best. Smudge stick might even help.

Sorry bout the big photo, it supposedly didnt upload then I cant edit to delete it.

-

Its ok Frosty.

Here, for those interested in weld spatter control or prevention of it sticking look up the thread "Question about controlling spatter". There done.

One observation tonight is that on this brand/model, the face is soft. The face was scratched by moving the stock around haphazardly. So if you want pristine, don't just half un magnetized what you are working on it to flip and turn. I guess take your time to properly move the stock.

Still works fine and isn't an issue for my use. For me, this thing is going to go through the ringer of a hard, well used life.

-

No problem Frosty. Enjoy.

Having my birthday when winter olympics are on I am all too used to people paying attention to it. I have no problem with someone being into the games. When you pop in we are still here.

-

As I believe it, it is just something as a coating to disrupt the adhesion of weld spatter from sticking to a metal surface. I haven't tried other stuff, I just buy the antispatter spray. I have used the nozzle tip jell as well. With both I notice a bit of a difference in spatter on things and or buildup in the nozzle. I'm not diehard on anything. If I want a clean job i do try to use both tho.

-

Same here with established places or people Scott. I get high anxiety in crowded busy places but I handle it ok. Never do get everything I need at a walmart. That place starts getting to me quick and I just want to get out.

Planter discs would make good birdbaths. A crank shaft would make a good pillar and something heavier for the base. Something bigger and heavier like that you'll want to try to make it as modular as possible. At least so they can take the disc off to pack it in the car. It isn't a must but you'd be surprised how many people will pass because they don't know how they would get it home not having a truck. Show the people selling them as well. Could be as easy as welding a bigger nut and bolt to the joining parts so it screws on.

Always love your wild ideas Frosty.

-

I see a lot of really nice birds being made with spoons forks and butter knives. I've wanted to try some myself.

If you want to go big you could make a scrap metal birdbath. Maybe a flower motif in the middle.

I made a humming bird a few back that the feathers were made using cold hammered finish nails. You could try something like that. People love hummingbirds.

There are a Lot of things you could do.

I like the birdhouse idea.

Glad to hear you'll be selling some of your work. Getting paid makes it a practically free hobby. I always enjoy when someone likes something I've made so much that they would pay for it.

30% eats a bit but if they can get a good price and they are doing the sales it could be worth it.

Other than seeing the faces of people who like my work, sales is not very fun for me. I hate sitting around and Im not usually very talkative being a bit of an introvert and all.

-

Sure, no problem.

-

Not to bad for eyeballing it. Doesn't need to be perfect

-

-

Have a piece of steel 4"x3.5"x9.5" that has a hole in it 2.5". Want to make an early type stake anvil out of it. I tried my 4.5" grinder on it but was getting the cut crooked. Thought I would try out the portaband on it. Sure with the other part being a vertical cut might have gone faster but tried it in the horizontal. Cut just fine with little pressure on it.

Ready to weld a shank on, then dress it. Debating welding on a small horn.

Anyway I am finding this useful.

-

Awesome price. How is the blower?

-

Never go train hopping while wearing Chuck T's

#1, that train goes faster the closer you get to it. Scary fast when it looked slow further away. #2, that gravel really hurts when landing on it with shoes with thin soles.

Show me your blacksmith pets

in Blacksmithing, General Discussion

Posted

All good George. Still much respect and sincerity. In fun is always good in fun.