remist17

-

Posts

83 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by remist17

-

-

Understood and thank you. I wanted to buy a made up batch to see how it is suppose to work before I start mixing my own. Thank you for the help.

-

I am reading many posts and there seems to be mix emotions on forge flux and what ingredients make it up. I have looked on several blacksmith supply places and they sell a verity of flux material. I would like to buy my first set to see how the “professional” ones look, react to the steel. Then I will try and mix my own. My question to the group is what type do I need? I would like to weld 1084 into RRspikes to make hatchets. Here are the options.

Forge Borax, 1lb, $10.95

EZ- Weld Compound- 1lb- low heat for tool steel, plow open hearth and Bessemer steel at low temps. Contains 40% metal. $10.95

Cherry heat welding compound – 5 lb can, low heat for tool steel, plow open hearth and Bessemer steel at low temps. Contains 40% metal. $50

There are also several liquid types.

-

Great information thank you

-

Thanks all; I am a little concerned since the forge is in a wood building. I put concrete backer board around the forge itself. The forge is cast metal (home made one) and homemade clay. I think the bucket with water or just a bucket and remove the coal from the building is the way for me. Thank you again.

-

Thank you for the posts.

-

Ok thank you all, my forge is home made. the container is cast and is clayed in. So I will continue to pull the coals out and let them cool down..

Thanks again

-

So I did some searching to find the answer but I cannot seem to find one.

How do you put out your coal forge once your done? I have seen pull the coal out and put it in water, cover it, put water directly on the coal while in the forge. Are these all acceptable >?

Currently I separate the coal/coke from the un-burnt coal and let it go out. Takes forever.

Thanks

-

Guys I'm sorry if I did not comment back on this thread. I elected not to contribute to the thread. I was wrong for posting the request without looking through the old threads. Have a nice day.

-

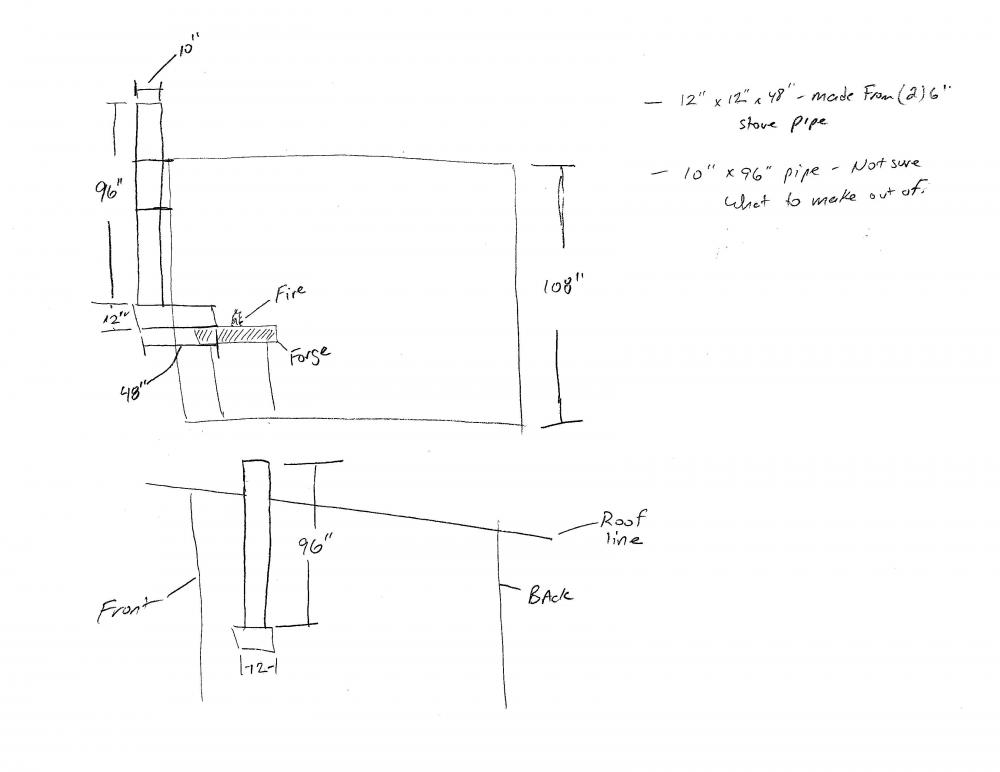

OK. I think I'm going to make the first run with the 2 6" stovepipe and then use galv roofing for the pipe. Thank you all!!

-

what are your thoughts on galv roof sheeting for the chimney? if that will work i have the plenum taken care of.

-

Agreed. I continued to call around to some of our ag service centers. i actually got hung up on when I asked if they had any of the empty grease buckets. Some people in my area are just not nice people.

-

-

trying to get a response posted but does not seem to like me today.

-

What can I make the horizontal tunnel out of? I see a bunch of ac ducts but they are galv steel. I was thinking to use the 6" pipe zipped together but I think that's the same size as vertical pipe. Sorry for the confusing dumb questions.

-

Frosty thanks never thought ofof that .

Anyone use 8" pipe successfully?

-

Been looking at side draft design. I have some 8" pipe about 10 ft from a old stove. Can I use this with a 12" x12" x3 ft rectangle that would go by the fire. Will the 8" work??

-

I wanted to put this in a post I had already started, but the forbidden bug got really old. So here goes, I wanted to build my blacksmith building over the old chicken run. I started my building this weekend. The actual dimensions are 7.5ft by 12ft. The old chicken run was a little smaller than I thought!

So my question is how far from the wall can I put the forge? The body of the forge is 26”x26”. I was thinking about 6” from the wall on all sides. I would like to run the chimney up the side and exit at the roof peak.

What is the average distance from the forge to the anvil and vise? I was thinking 1 step to anvil and 1.5 steps to the vise?

Do I need to side the barn in metal or can I use wood siding?

What is the easiest way to make a hood? I currently have 8” chimney pipe that is 6 ft in length and two section of unzipped 6” pipe that I was going to try and make the hood.

Thanks

-

Not using railroad ties but RR track. I m putting it on a 6x6 or a oak stump.

Thanks

-

Frosty I big hunk of steel that I got i think is better than anything I have so far. I put it on a stump and did not secure it. Put some rebar in the fire and started swinging away. Made a fire poker and the block never moved. I plan on building my own little smith area under roof and at that time plan on securing all the "anvils" I have. I opened my eyes to other types of anvils since I could never afford a actual anvil. Anvils in my area that are really in bad shape are starting at $300 bucks. I just joined a club and hoping to watch the tailgates at the meetings to pick up one.

Question:

I set up my forge with an old squirrel cage blower from a old water heater. It blows at one speed and too much for the coal. I made a sliding gate out of some 1/8 steel. I drilled a bunch of evenly spaced holes and put a pin through one. I can put the plate down almost all the way closed to all the way open. My issue is I am not sure what the correct amount of air is for coal. Can someone point me in the right direction on this?

-

I plan on using the RRT and flat block along with a cheap 70# cast iron anvil. So I will have three stumps set up, forge thats about 3' in diameter and a small work bench. I plan on just putting plastic on the walls until i can afford wood siding and a metal roof. The chimney will come out of the side wall.

-

Right now I would be doing small projects nothing larger than a 12" section. If I go to a new building my township gets me for over $500 in permits and it goes up as the square footage goes up. If I can use a existing building (chicken run) I can make it taller, just not longer. I was standing in there last night thinking this is way to small....

-

I will take the photos tonight.

-

Thank you for the reply on the RRT I like the fuller. I do not have one yet. I appreciate the support. Is a 12x8 building sufficient to work in. I have a old chicken run i was looking to convert over.

Any suggestions on the post vise and welding to it? The hold downs look cast iron, but I could be wrong.

-

Do I need to temper the RR track if I turn it on end? I'm not sure if I would screw it up if I tried.

Post vise question

in Vises

Posted

I recently picked up a post vise for what I thought was a great deal. It has no identifying marks on it that I can find. The threads are great and the jaws are even. The only issue one of the mount ears are busted off. The mount comes off the bottom jaw connection and splits into a fish tail .The one tail is broke at the split. Can I weld a new section on or is it ok as is? I screwed the remaining tail with standard wood screws and it seems to be locked in place. I plan on using it for light twist work or holding light work. Nothing over .50"

Ill try and get some photos.