-

Posts

448 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by templehound

-

-

Ridiculous 20, secondary 40....I am not certain what do you like to say/ask....

Mostly I grind blades down to a thickness of 0,20-0,30 mm so that they flex on my bare thumbnail.

A blade that is ground so thin and sharpened with a primary bevel of 20 Degree , is not ridiculous at all.

Well, that cuts like poison!

Those 0,20-30mm can be easily stropped down to zero....rolled edge is the term, I guess.

That is the old school and best edge You can get on a knife blade.

Based on that, the "meat" behind the edge determines how strong Your edge will be....

So the secondary40 means the blade flanks?......please enlighten me

Cheers

-

Thanks for the fine comments, Gentlemen!

-

-

Somehow I missed that one.....IMHO slip joints are more fun to make then using them.

...and they come not easy off the bench.

This one looks great!

-

Frosty, Pnut, thanks for your comments!

They are appreciated a lot!

-

Here are three of my recent folders I made the last months.

As they come in unetched Wirtz-Damascus with Padouk, O1 with Ceylon ironwood and etched Wirtz-Damascus with Indian almond tree.

Liners are springy hard titanium 6Al4V, locking springs are high tempered1095 and the screws are hardened low carbon steel.

Cheers

-

Increase the carbon content of 1095 high carbon steel? it has already 1% Carbon!..

Steve said it already, Why?.......for what?......whats the point in this?

I just dont get it.....thats not crazy, please forgive me with all due respect...thats very close to silly.....but I will not offend You, dont get me wrong here.

It is contra productive.....it will go at least 0,10mm deep from both sides of the blade.

Youre edge and tip will pop off due the lack of toughness, it turnes out super-brittle....and you can temper as you want....it wont change anything.

Dont waste your time and money, dont ruin good American high carbon steel!

do and try something more reasonable instead.....but like I said, no offence.

-

Hi there my friend.

first ....who would blame You for the amount of pictures? The more the better! for us looking at your skilled work is entertainment and we are not overfloated with that, arent we?

To make a living with making knives(or another craft) needs a lot of discipline....I say, more than if You work for somebody from 8am-4am....it more easy to get distracted by some " knife playing in the backyard" ....of course said from my point of view.

as ever you show a nice asian influenced row of wild useful tools

all looking undestructable and pretty mean

And....he year isnt all over yet....keep them coming!

Cheers

-

On 9/24/2019 at 8:41 AM, DHarris said:

Do you have a website or a gallery of all your past work all in one spot?

Yes, I have a website but it is way too old,....no update since years.

I am working on a new website but it really takes time.

best place to look at my work is in our German forum

Cheers

On 9/24/2019 at 8:59 AM, Chris The Curious said:Templehound, I bow to you. That is a beautiful knife.............and the sheath is a perfect compliment.

Thanks a lot, Chris!....much appreciated!

-

On 9/21/2019 at 10:14 AM, DHarris said:

Beautiful work.

Someone has likely asked before, but do you do your own leatherwork?

Iron, as in literal iron? I assume so, because on a BladeForums post of a knife you called The Ghost Dog you said its bolster was mild steel.

Thank You, DHarris!

Yes, I do my own leatherwork.

Well, actually it is wrought iron.

Cheers

-

Thank You, Daswulf

-

Thanks a lot, Guys!

-

-

Is it flat tang of hidden Tang?....on the picture it could be both even if there no pins shown, it could be both

sometimes the questions are so simple that I have a problem to understand them....

Cant You find a a piece of crap mild steel?...just something like 100x40x6-8 mm?....or bigger or smaller?....

just by a piece of construction mild steel at your local dealer....maybe cost 2$?.....?

....and by the way....if you are a beginner in knife making, try to keep it simple!!!

.....front bolster is enough for the first round.

good luck

-

23 hours ago, ThomasPowers said:

"Give me an hour and I'll have a website up "proving" that they are the lovechild of Margaret Thatcher and Elvis."

..... there we have it.... a rail road spike and a wrench having a lovechild.

-

Oh my God!....Wrenches, rail road spikes.....rail road spikes and wrenches....

they come with low carbon and while forging this low carbon is even less...

....and yes burning them off is hazardous to man and air polluting....

Apologies, but...after millions of educating posts they are still a pest in the knife world.

-

Thanks Awrksmokey!

-

-

Thanks, Guys.

-

-

SLAG - Thank You very much for the fine comment, Sir!

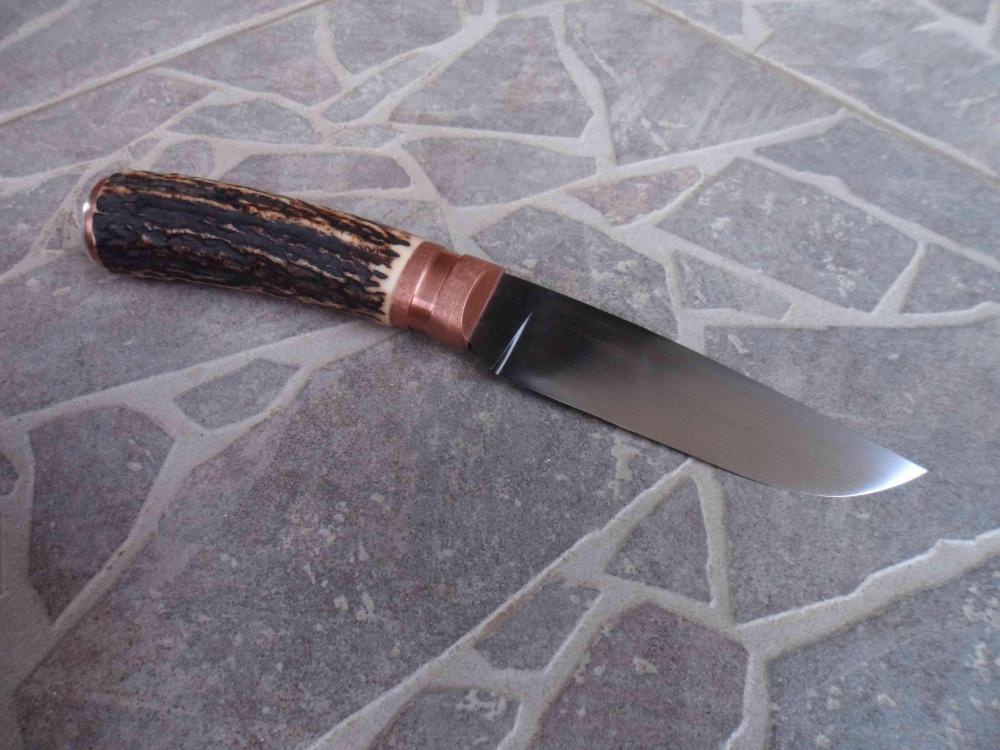

One handle is steller bone and the other is water buffalo horn.

Cheers

-

Les L, gmbobnick, FatFrumos, thanks a lot for the nice comments.....they are much appreciated!

FatFrumos, generally I use everything that reacts on copper....best results I get with liver of sulfur.

I spread it on the copper and let it stay there without cleaning it off....so it can react on and build a thicker layer of oxidation.

here in the tropics it is very easy to age copper....the high humidity helps a lot to get a patina faster.

-

Well, that learning curve never keeps straight, always upwards but never straight.....

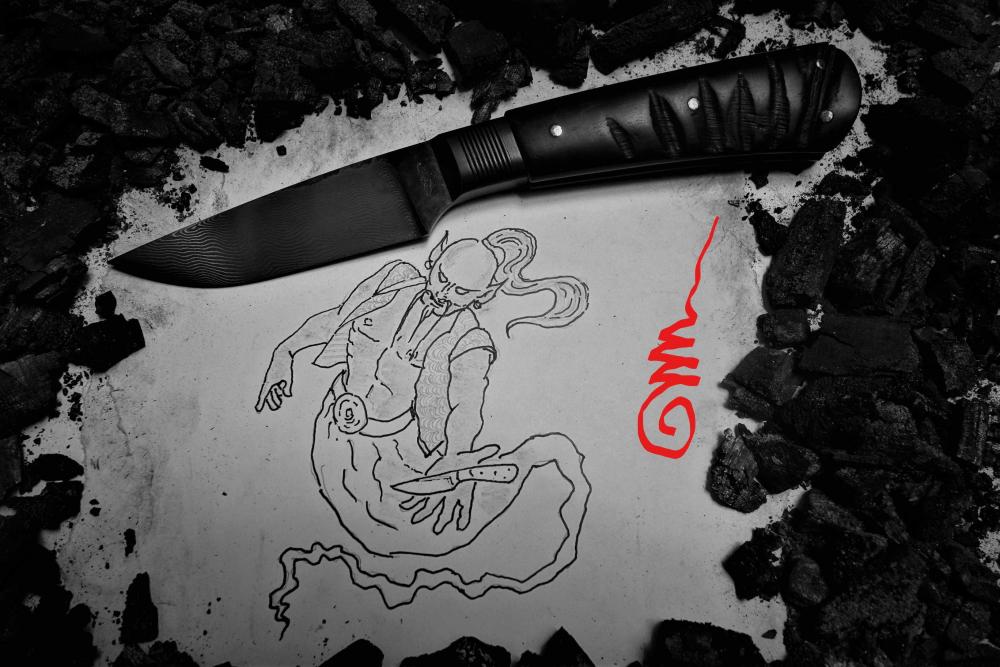

So here I am again with two of them ....they made me sweat and think like they always like to do.

No knife design will come to my mind, that looks more like a tool than a Finnish puukko with a barrel shaped handle.

While the rudimentary basics of the blade form is in shape and size comparably easy to make,

....but the effort of eye balling in that handle form is enormous...at least to me.

If I forget a moment to stay true to the crosshairs, I can easily loose my touch to the form.

And after all, a traditional back stiched sheath can make me find myself or loose myself....

...and that kind of knife sheath is still definitely a different science for itself.....

...as they come in Tungsteen tool steel, copper, bone and horn.

the blades have ridged backs and riged ricasso choils

With true ferrules and the tangs riveted over their butts.

cheers

-

Question about bevels

in Knife Making

Posted

Thats what I thought.

so the answer is definitely not" Yes" ....that aint a smooth transition...pretty coarse wedge