-

Posts

448 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by templehound

-

-

I like them both, but the upper piece is awesome....what an aggressive profile...wow!

-

Insane of amount of quoting and picture removed

Will, absolutely beautiful!...did You ever post that knife somewhere?...could be I missed something.

-

As always... Woah!!

I think it is really cool to find a hidden detail or a little touch that you don't see right off the bat. It's like the etching on an old pocket watch movement.

Thank You, C-1ToolSteel!

-

-

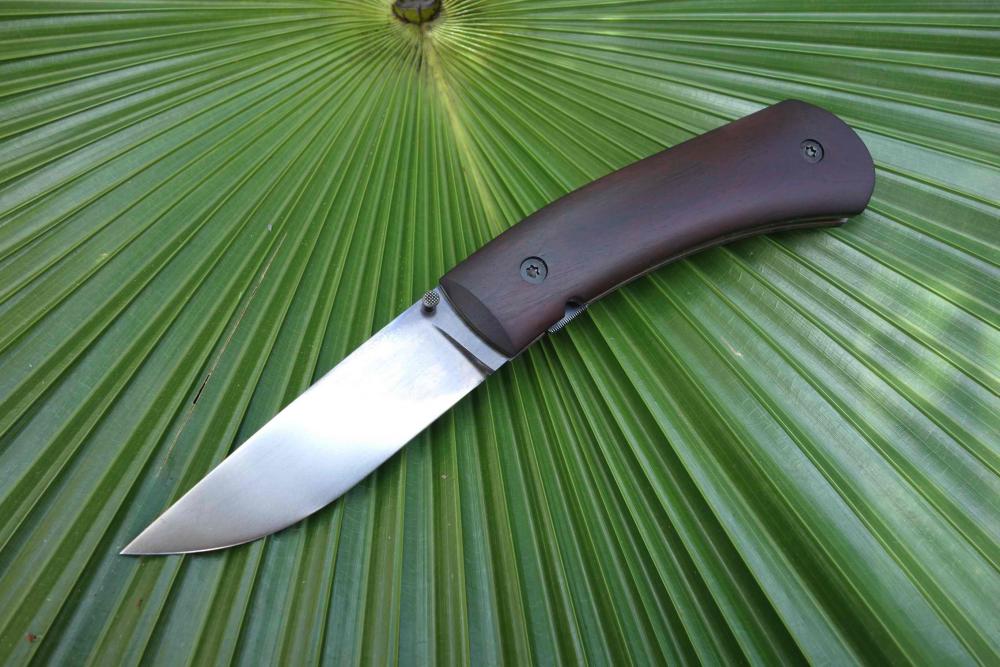

The materials are the same, Boehler TWR 1.2513, Ceylon iron wood and 6ALV4 titanium... reliable and proven as the design....and if You do something that many people like, get prepared to do it many times...

..honestly there is no fun in making, only concentration and discipline, the good feeling comes when its finished, than I can let go and enjoy what I have done....

so I appreciate new things that I can use like the detent ball which is made of artificial ruby.

That stuff won't wear down in the next 20 years and it looks awesome...

Even if You only can see it when dismanteling the knife for maintenance, which customers really should do with a fine mechanism.

If You don't maintain Your gun, it will go down...same with folders.That's what I always tell customers...care for it!

Back drop is phloem/bast from coco nut palm.

Well, here is another one for the fridge.

Cheers

-

There You go!...You trying different styles, thats good...and this looks like a reasonable field companion with good old school "forest, field and meadow - steel" as the O1 is often nicknamed in Germany.

Very well done!

-

16 hours ago, jlpservicesinc said:

Nice all the way around.. How long did it take you to put the knife together including gathering all the materials? did you use a belt grinder on the blade?

I am linguistically not sure what You mean with "gathering" in this case, if You mean having access, getting my hand on the material, then I just have to take it out of my stock...but if You mean how long it took me to decide what material to use, than the answer is, not long.

Because mostly if I have an idea for a knife, the colors are an important part of the inspiration and sometimes materials or myself are failing and than I take whatever it takes(well,abandoning the inspiration of course

)to get the knife properly done.

)to get the knife properly done.

It took me one year to complete.I never made a traditional Tanto and a lot of time I spend with research and educating myself in the Japanese way of Tanto making....it took me two handles, two sheaths, and a hand full of mekugi pegs and a lot of "discipline" to finish it.

it was one of the most difficult knives I have made until today, and I once thought this is not in my abilities...several times screwing up major parts, putting them away until the frustration faded, and then made it new again and continued working on it ......that really felt like "the way is the destination".....

the blade is ground stock removal with my belt grinder.

Thanks, jlpservicesinc!

-

16 hours ago, C-1ToolSteel said:

Woah!! I can't think of anything to say. That knife just speaks for itself...

You just said the right thing, Thank You,C-1ToolSteel.

-

Thanks a lot for the nice comments, Guys!

Dave,.... Katanas, Wakizashis, Tantos are traditionally all take down.

The advantages are easy maintanance and repair of all parts.

The little tool is made of a bufffalo horn tip and ivory and it is to push the pin(mekugi) out of the handle.

It seemed necessary and harmonious to me in a certain way, to finish this with a traditional stand.

Cheers

-

-

Strongly inspired and influenced by the Japanese movie "Samurai Fiction" I didn't followed the traditions in the process of making.

Like in the movie, free style is one of the plenty ways besides tradition, that leading to the desired result.

I took clay covered 1095, copper, some unknown hardwood root, gave it the overall length of 10 inches and get this fiction of a tanto.

for those who are interested in the movie here is a trace to find, do not notice the synchronised versions, watch the original with English undertitels to get the full blast of fun....

https://www.youtube.com/watch?v=TknAs5CrY9s

Cheers

-

I enjoyed the pictures of the kids showing their knives, I wished there were more faces with the associated knives.....and the red haired boy with the mint colored handle is IMHO very good.

Extreme tension line of a fighter that dont go out of control,... very well proportioned!

but above all, it needs somebody who is able and good in teaching people, especially kids....

...to me it seems that You are very good in this Theo

-

-

Those Scandinavian sheaths are a world apart for themselves.

In most cases I need 2-3 attempts before I get it right ...difficult stuff

So it takes always several days or sometimes weeks before I am able to rouse myself up and complete the job.....

Leather is half tanned with a raw hide core and blade section is lined with wood.

Cheers

-

A bit pointy but the Puukoo shape overall is real nice .....take care with that stitching groover.

-

Practical, sympathetic handle in unusual material combination behind a useful blade with good allround edge.....I like the knife a lot... and Your good intensions also increase it overall.

That hammerhead shark signature is awesome!......

-

On 7/27/2017 at 9:34 PM, Gergely said:

Beautiful blade! All of it is plain joy to look at. I'm a big fan of your works.

Bests:

Gergely

On 7/27/2017 at 11:53 PM, Daswulf said:I'm a big fan as well. perfect design and flawless execution. It is always an inspiration.

Gergely, Daswulf, there is no bigger compliment, Thanks a lot, Fellas

On 7/28/2017 at 10:22 AM, Scrambler82 said:Beautiful Knife and your display pictures are well executed also.

Torx cross bolts, nice look !

Thanks for the fine comment Scrambler82 !

-

They make me thinking about making one for me too.......Super!

-

Design, size, material on this locking liner are rather familiar, except the blade steel called TNT Triple6.

It is one of the creations of my friend and highly respected colleague Achim Wirtz (wootz@web.de), who creates steels and alloys like music.

The most important ingredients of this cold work tool steel are about 1% C and Tungsten, Niob and Titanium 0,6% of each.

This results in one of the most sophisticated steels for knife blades...the flipside of the coin is its workability that I can literally describe as vicious...I never had a steel that screwed up my concept so often....and after successfull completion I promised myself never to work with it again.

Just after testing the blade, I knew I only have to wait until the troubles begin to fade and than maybe, (probably) I am on it again.....

Cheers

-

Superb contrast in the etching of the rope pattern allows to conclude the right amount of heat during the welding and forging.

Very nice work!

-

Will W, jlpservicesinc, T-1ToolSteel, will52100, Jspool, LouL,.......

Thanks for the nice comments, Guys!

-

On 7/20/2017 at 3:09 PM, MastaStan said:

Amazing, really love this knife! I think it would be nice with a matching bone sheath, just an idea.

Think I'm going to be trying to make something similar to this (doubt it will be of the same high standard)

Thanks for sharing!

Thanks MastaStan!......with a matching bone sheath is in deed a nice idea.Sadly it would raise the price of the knife merciless, and bound to custom agreements this one goes out with a leather sheath....but I will do that on another one.

Looking forward to Your Puukoo!

-

Jspool and Shamus Blargostadt, Thanks Guys!

-

Hi Will, I guess that guitar strings maybe have 1% Carbon. Springs in watches, pen nibs and things like that often have 1%C.

(At the end of the thicker strings mostly the tempering color is visible and its yellow-orange)... on D'adario strings it is good visible.

But I think, it will be very difficult to fire weld those thin wires flawless.

You can try with some effort and weld closing it in a small case or box to get the atmosphere out and then with a single first push on a good press or two, three blows on a good dice it might work.

an acceptable weld only from strings I guess that needs precise preparation, good equipment and above all a bunch of experience., maybe adding some steel powder(with different, less carbon content than 1%), to fill up the gaps would help to make the project a success .I would leave them straight and not try to twist them together, they are springy hard, needed to be annealed and it will come out in an uneven twist or whatever.

And keeping the package small it enhances the success to " the cause ".

Puukko images

in Knife Making

Posted

Well done kumppani! I like the combination of the handle materials a lot

The only critique I have is the file work on the blade spine, a bit to coarse and IMHO always making blades looking less serious....but that is a matter of taste, You like it so its fine.

The only Puukoos I have made I recently posted already...maybe makes not so much attractive sense to post them here again.

But one or two images more of Yours would really enrich the threat.

dont forget to show us the sheath when it is finished.

Cheers