-

Posts

195 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Shamus Blargostadt

-

-

I'm guessing that forging a proper tomahawk drift is an advanced project?

-

Perfect! Thank you!

-

ok this is going to be a really dumb question.

If I want to buy some 1/4" square or round stock bars to start out forging some scrolls and other simple projects.. maybe tackle a set of tongs, what do I ask for at the Steel-R-Us store? Just "I'd like to buy some 1/4" square and round stock" or are they likely to counter with, "well buddy what kind of steel stock you looking for? We got 01, 1060, CPM 10V, some D2, or how about some L6....etc.. etc.. etc.."

I just want to heat up some steel, smack it around, and learn how to make stuff.

-

Thank you again Sir!

-

All that said, you have the fire pot built from a break drum already, ash from the coal, or a bit of clayed soil will make a ok slope/bowl out of the square sided drum, and if its to big? Again just use mud to line the drum and make the bowel the size you need. As to the forge shape? As long as you want the cool look and understand the limitations, it should work. Google image shearch will turn up the original.

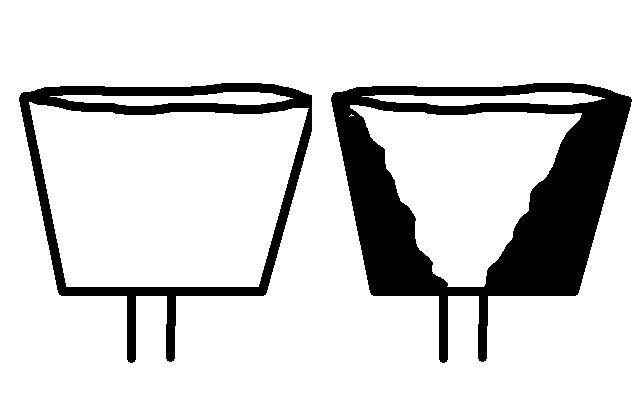

Charles - The break drum I have is about 13.25" internal diameter (top) and about 5" deep. If my air is coming in from the bottom, are you saying the pot should look more like the drawing on the right, below?

-

Thank you very much guys. As always, greatly appreciated!

-

yes i have the break drum forge part built. it's propped up on cinder blocks. I took to heart the advice of folks here to consider a chimney.

I don't know how to weld but a buddy says he has the scrap i would need to make this and I know a guy who will quote on fabrication and welding it.

-

I'm thinking of fabricating the forge in this video. I was wondering on some vet thoughts on the design of the firebricks and the firepot location in relation to the chimney. Most coal forge's I see in videos have the firepot in front of the chimney. This is the first time I've seen it in front.

Do you guys/gals think having the firebrick around the pot is helpful? How about if the bricks lined further up to the front, so the firepot was surrounded in the back and sides?

the only problem I'm thinking is perhaps it will be harder to tend the fire, removing clinkers, etc..

the break drum I have is slightly larger than this one in the video, probably by 2"dia. I also have enough firebrick to come to the front. Just wanted to make sure I wasn't making a mistake before launching this.

-

Steve - I've had two of those calls. Both times I had great fun wasting a half hour of letting them attempt to walk me through hacking a Windows PC, when I run Linux. Both times I got switched to an "expert" who proved to be just as dumb as the first guys. I just laughed my rear off at the stream of curses when I finally get tired and tell them it's a linux box and that they should get a real job.

Die Hard Unix/Linux user here. I started with AT&T System V Unix in the 90s and refused to put microsoft anywhere on my resume since.

BTW - the images look fine to me.. using ubuntu and chrome here.

-

That sounds like a prudent approach Scotty.

There is a flea market here with a selection of cheap crowbars, chisels, and hammers (smaller mass ball peins and claw types), usually around the $3/ea range but might go cheaper if I buy several. Any recommendations on what kind of tools I could consider making from those types of things?

-

That unit in black frog's video appeared to support metal. "variable speed" and it even had a label saying to use a 24 tpi blade for iron and steel.

-

That's a pretty nice price for a cutoff saw, kubiack.

thank you all, really great info.

-

Porta-bandsaws are fantastic.

bandsaw would be ideal for this. I'm limited on funds though.. was hoping to keep it under $60 if possible.

I bought one of the hand held grinders from Harbor freight that use the 4 and 1/2 inch wheels. I also bought some 10 packs of the thin metal cutting disks. I have cut both thick metal (it was either 1095 or D2 a half inch thick), truck springs, leaf springs, etc. using my hand held cutter. You can lock your piece into a vice and the metal scribed so you can follow the line you want to cut. It is real easy to cut the leaf spring either width ways or long ways if you wanted a longer piece for a knife. I have done both. I always wear leather gloves , a thick cotton apron and one of the Harbor Freight cover your face face masks when I am cutting metal due to the pieces that fly around and the sparks. I also wear eye protection under the face shield as pieces can get under the shield. I thionk I paid $9.99 for the hand held grinder, $5.99 for the cutting disks and $1.99 for the face shield. The gloves were probably 2 bucks. I have cut everything from spring steel to wrought iron with this set up and it works well for me. You don't need a $500.00 cut off saw to cut metal pieces to forge.

Ohio Rusty ><>

The Ohio Frontier Forge

ah thanks Rusty. That's really good to know. I'll look at getting a face mask. You've had blades disintegrate then?

-

I hit on this topic in a totally unrelated thread and wanted to ask another question. Thought I'd start a new thread for a beginner like myself looking for the same answers.

The background is I acquired a leaf spring 1/4" to 1/2" thick from a scrap yard, and was trying to figure out how to break it down into workable chunks, being limited in tools and knowledge. I do have a makita chop saw but the general wisdom appears to be that it is designed for wood and using it for metal has a good chance of breaking the unit, at best.

One good recommendation I had was to find a hacksaw blade that was 12 - 14TPI to saw it with. I found a 14tpi but it was really slow going. Another person suggested getting a bandsaw blade made for cutting metal and cut/punch that to install into a hacksaw. I'm in the process of finding a blade to try that.

In the mean time, a local hardware store had a sale on Genesis 4.5" angle grinders for $20. They have terrible ratings on amazon for burning up and failing. I figured I'd give it a try and take it back if the motor burns.

so.. to my questions. The angle grinder worked pretty darn good. I cut the steel with just a few breaks to let the motor cool down and used the 14tpi hack to move it along. It was a little scary though. Having been blessed with a vibrant imagination, I could easily envision the grinder blade disintegrating into shards, embedding them into my forehead and taking off fingers. It got a little less scary with time but it was hard to keep the line straight cutting freehand like that. I'm thinking curved cut and straight high speed circular blade isn't such a good thing. I want to cut it lengthwise now, for blade sizes.

Has anyone used a sawzall/reciprocating saw for breaking down this size of steel?

-

That is one nice forge. Makes me wish I knew a welder, or knew how to weld. I wonder how much a shop would charge to make that table and hood setup.

-

I recognize the ambient noise. You just got peeps! Sounds like my basement.

thank you for this, I was just wondering what the next step was going to be in my break drum forge

-

I saw a 350# Sweden Anvil at a flea market for $1500 last weekend. Looked beautiful but holy cow that's a lot of clams.

-

I'm much obliged gents. I'm going to give both methods a shot. I wish I had started a new thread for this question.. really good info for a noob like me.

-

The lowest tpi blade I could find was 14. It cuts but it's going to take a loooong time to break it down with a hack saw. I do have a chop saw. A bit embarrassed to admit I don't know the answer to this but can I get a blade to use in it that could cut this? It was passed down from my father-in-law who has since passed on. I've only seen them used for wood so it didn't occur to me that it might work for metal too. He was a hobby wood worker and left behind some nice wood working tools.

-

the bar is 3" wide, 38" long and 3/4" thick in the middle.. then it tapers to 1/2" thick on the ends. I mean to get a good angle grinder at some point but don't have one yet. I wouldn't have thought a hacksaw would be a good route but I'll give that a go Frosty. Thanks for the tip!

I'm definitely seeing some axe heads in this Ronin. I'm wondering if I can cut a length, smash the middle down to make it thick enough to take a handle hole (ignoring the fact I don't have a drift yet) then flatten the heads for an edge.

-

ugh... was hoping a chisel and hammer on it might work. It's not in front of me... maybe it's 1/2". It looked like it was off a truck. Definitely thicker than the 1/8" stock we used for our knives.

-

I just picked up a bar of 1" leaf spring yesterday. I was thinking of doing that very thing Jeddly.... as soon as I figure out how to break it up into smaller bits.

-

-

TP - yes that's kind of what I had in mind too. I have a couple tongs and a hammer but none of the chisels he uses. I was thinking of hitting the flea market up for scrap tools to modify first. The S shape of the body and twist section for the candle holder resembled some of the first learning tasks in the books I'm reading. "The adventure [knowledge] is in the journey, not the destination."

"heat shrunk in or forge brazed" - thanks I'll check those methods out!

Beginner steel stock

in Blacksmithing, General Discussion

Posted

Yes I did search, asked around and read up to find sources. I just didn't know what to ask for, specifically. I'm still trying to learn the language and lingo of smithing.

Oh and had a metal shop owner invite me over to rummage through their scrap pile last night!