-

Posts

195 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Shamus Blargostadt

-

-

very nice, thank you for posting the progression pics!

-

-

Ah sorry for the double post. Posted this first one from work and it said it was blocked for being a hacker site when I hit "submit". Just posted again with pics.

Thank you you for the comments all

-

Forging a knife (sushi knife) and when forming the tang I got a crack. Can something like this be hammered out or do I have to abandon that whole end and do something else with it? Still learning and not afraid to learn the hard way, I just don't want to waste time and coal if it is futile.

This is leaf spring material from a truck.

thank you!

Sorry for the double post. Unintended

-

I think I know the answer to this but just to be sure... I'm making a knife (sushi) with a hidden tang and the top part where the tang begins to form developed a crack (visible on one side, not the other) I'm still in the forging/shaping stage. Is this something I can continue to heat and hammer the crack out or do I need to cut it off and just switch to a smaller blade?

-

even my low setting (cheapest blow dryer I could find) sends way too much air. I need some kind of flu to cut it down. Too much air burns up the fuel too fast and burns up my steel. My son is constantly melting his pieces by turning on the air and getting distracted.

I use coal.

-

What was the forge like that you guys used?

-

What grinder(s) are you using? Does it have a variable speed motor? What height is the work rest set at in reference to your body? What grits and stages are you grinding in? Are you using a push stick to hold the blade against the grinding medium, or are you trying to hold it with one of those thumbs until it gets too hot to touch? All of these aspects of grinding affect the finished outcome. Give us some idea of your process and we might be able to give you some pointers and lessen the learning curve a bit.

whew, tried to reply several times over the past couple weeks but kept getting "permission denied".

I have a craftsman 2x42" belt grinder, single speed. It feels a little high, chest level. I've been holding the blade with leather work gloves while grinding (pain is an excellent instructor!) then cooling in a water quench bucket.

I've been struggling with position on the belt.. not sure if I should use the small "slack" area or against the metal backing, or the arm flips down to allow grinding against the larger bottom wheel. My first attempts at hollow grinding against the wheel were awful.

I'm able to muddle through producing a blade but I'm introducing a lot of flaws accidentally that seem to be near impossible to erase.

-

despite your indicated flaws, this looks great! Very impressive!

-

Nice. The only minor down side I see is if you want to say heat the middle of a long piece for some reason. the fire pot doesn't extend out from under the hood enough for that, and the angle iron hood supports are just about where I'd want to put the steel cross wise in the forge if I wanted to do that. I'd find not being able to work across the forge that way a bit of a nuisance, but that's because that's how I've always worked mine. No really big deal, you can always correct that in later incarnations if you find a need.

actually the bricks, hood, and hood supports are not fixed. They're all removable. It's all heavy enough to stay in place without welding it.

I do run into length issues though. I had a hard time getting that entire knife length hot enough to heat treat.

-

Yes, actually in the mechanical drawing I made the angle steel the table rests on are supposed to be facing up, instead of down, to create a rail. He had it welded together though before I even knew he was thinking of welding it. No complaints from me though

I was thinking I could probably use that inside my garage, with those bricks in place, and just find a way to pipe the smoke out of the garage. The fire can be light-yellow hot and the outside of the bricks are barely warm to the touch.

-

That's the sushi knife project I'm working on there on the table. Just heat treated it and did the first temper today.

-

welp, thanks to the inspiration of another thread in here, I had this made. Working pretty good but I need to build up the drum with some clay. Including design print too. If anyone wants the .dwg to modify, just let me know. There are 1.5" angle brackets welded to the bottom, 3 sides, so the drum just slips into it. Easy to replace if ever needed. The hood sections aren't welded on so they can be removed and the circle cutout replace if I ever want to use it for a table. Maybe to hold a propane forge down the road.

My buddy works at a fabrication shop and supplied most of the material from scrap, and just charged me $50 for the stock he pulled off the shelf, then welded it for me (and gave me a welding lesson to boot!) Can't beat that!

It does a great job keeping the smoke out of my face. I used firebrick just like the original guy I plagiarized did but I don't think they're necessary (an elder from church gave me a case of them!) I can just take them out and use them for a propane forge some day.

-

for the sake of noobs like me - I've grown much more comfortable using this cheap ($19) 4" angle grinder. I'm tearing through this truck spring pretty nicely now. It takes about 20-30min to cut a bar out, using light back-and-fourth motions (rather than just digging in and cutting it like a piece of wood)

-

I'm still chopping up this scrap truck leaf spring.. so practicing swinging the hammer and grinding

I noticed there seem to be a lot of different jig designs out there. Can anyone recommend a tried and true one that isn't too hard to make that would work on my craftsman 2x42" belt grinder?

-

yeah I think I might need to make a jig. My first attempt at a hollow grind looks like a funhouse mirror.

-

man I feel like I have two left hands, both full of thumbs, trying to grind blades. I can't believe how much I suck at it.

-

just as a follow up, I cut halfway through with the grinder then hot-cut the rest of the way (with the help of my son) Now said piece is well on its way to becoming a sushi knife!

-

ah, that explains all of the cold hammering I saw on various videos on forging sushi knives.

-

I was going for one steel (spring steel) I'm still a beginner. Always wanted one of these but could never afford one.

-

-

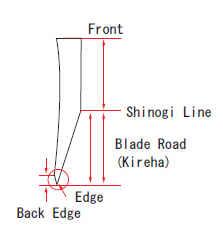

Hoping someone may know about sashimi/sushi style knives. I notice that the handmade ones usually indicate if they're right handed or left handed. Every picture I've seen shows one side of the blade and a typically round symmetric handle. Does this mean the blade is sharpened on one side or do they get ground a special way, or perhaps both?

Hoping to make a couple from some leaf spring steel as my next knife projects. Any tips appreciated.

-

"lunch buckets" are popular around here.. usually a small cooler or large tin lunch box. Definitely big enough to warrant a forged hook as a beginner project!

-

I was looking at a few online. They seem to range between $25 - $38. Shipping tends to double it though. Is a bull pin something common that could be bought in a steel supply or home depot type place?

I did pick up a huge chisel looking thing at a second hand store with a mushroomed base, about 12" long and approximately 1.5" - 2" Diameter. I'm doubting I have the skill to draw this to a useful taper though.

First sushi knife

in Knife Making

Posted

Thank you Charlotte! I was trying to do a Japanese edge, bevel on one side and hollow grind on the "release" side but my grinding skills were not up to the task. I'm going to need a lot more practice on the grinder.